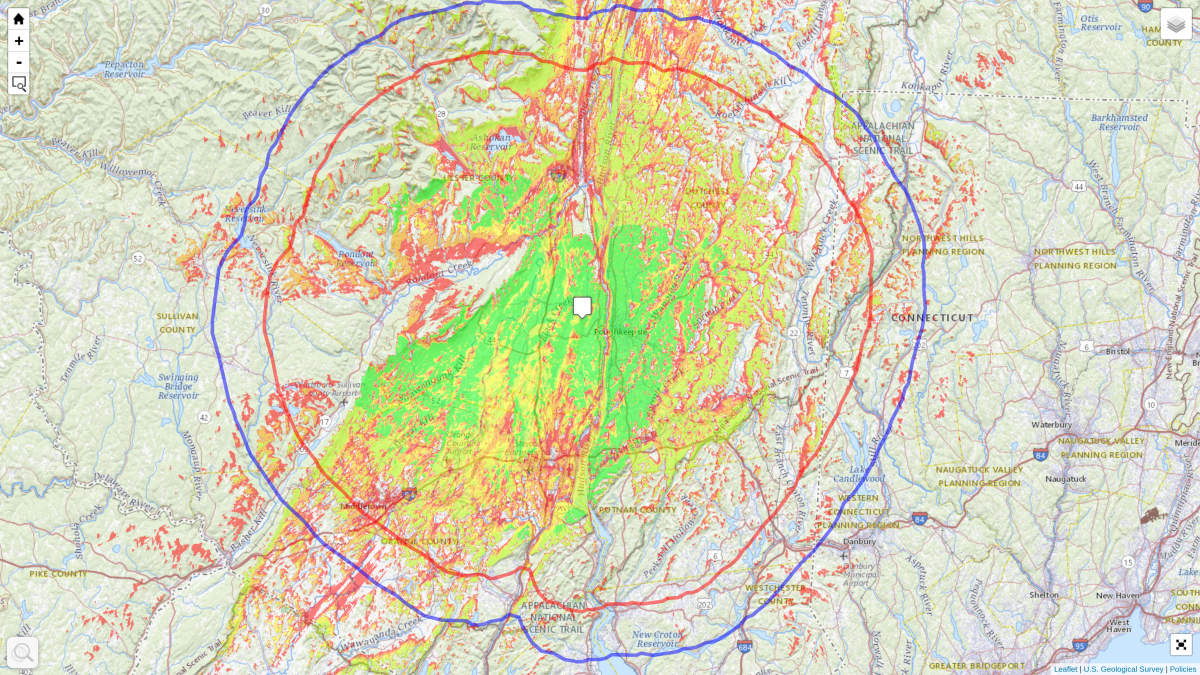

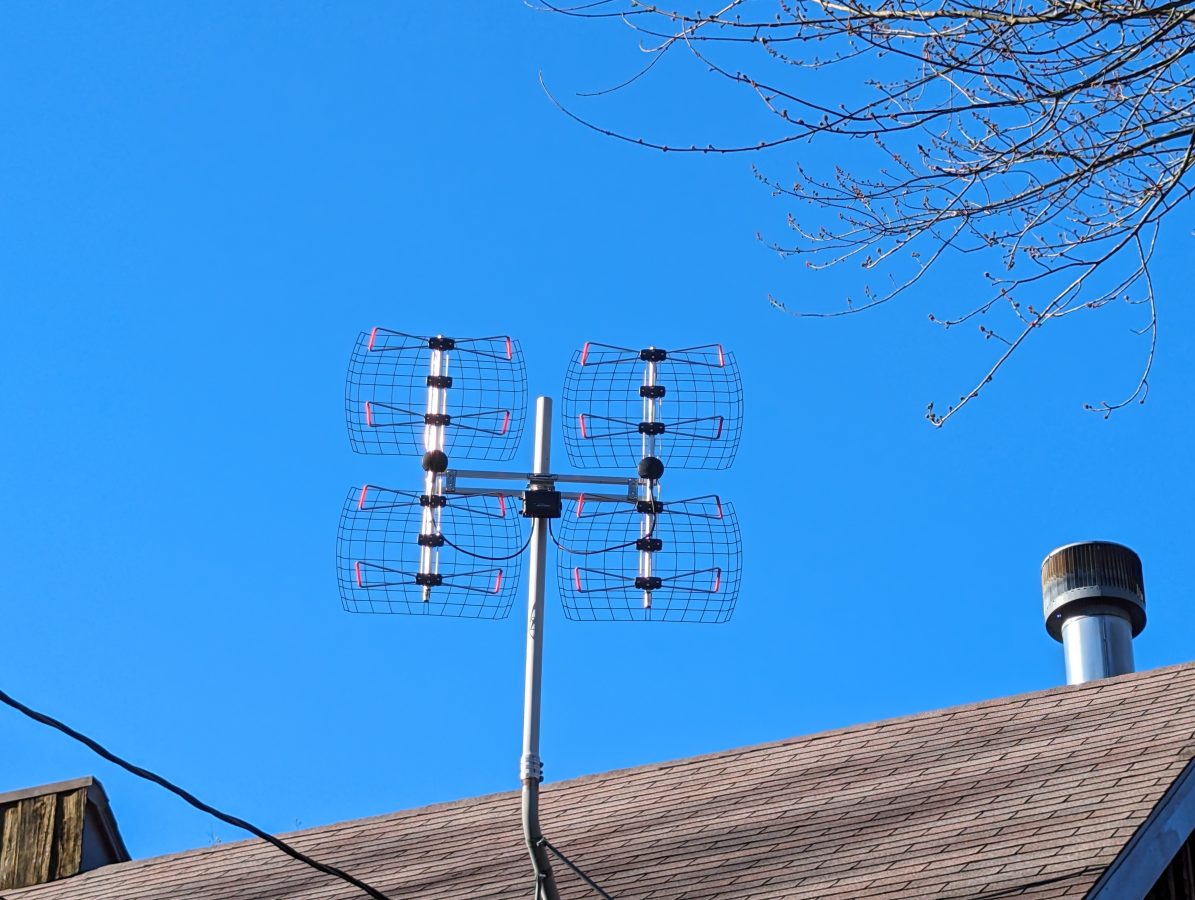

One of the many projects we are currently finishing up. Over-The-Air TV is making a comeback.

A few things about LPTV; These stations usually have an ERP of 15 KW or less, and they are a secondary service, like FM translators, which a full-power TV station can displace.

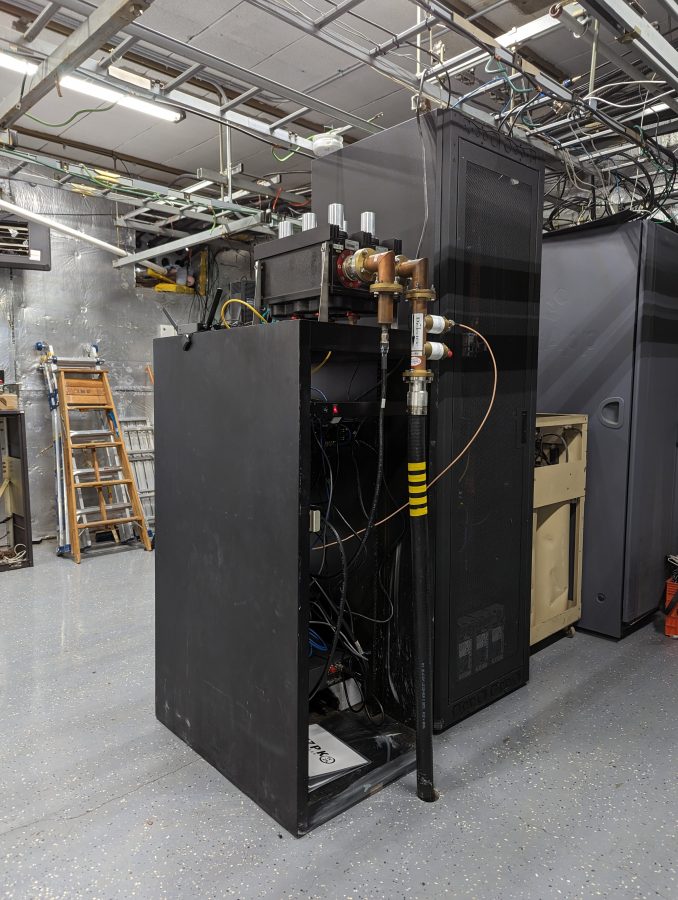

This is an ATT microwave site built in 1977 according to county records. This may have been one of those VHF Mobile Telephone sites which existed before cellular telephone systems. ATT owned it until 2022 when it was sold to a private business.

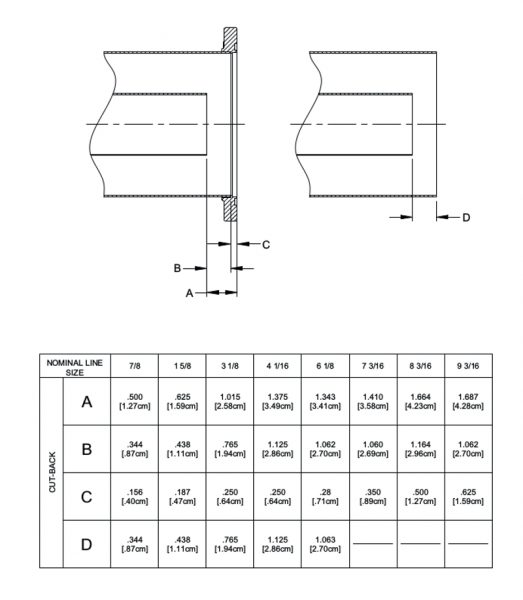

This station is on channel 31 or 575 MHz center frequency. UHF TV stations often use slot antennas, which have gobs of gain. Slot antennas are simple designs that have a broad bandwidth and until recently were mostly horizontally polarized. This particular antenna is elliptically polarized which is becoming more common as TV providers are looking at mobile video applications.

Slot antennas are the inverse of a dipole antenna. A dipole is two conductive poles approximately 1/2 wavelength surrounded by free space whereas a slot antenna is 1/2 wavelength of free space surrounded by a conductive plane. The width of the slot determines the bandwidth of the antenna. Radiation from a dipole is in the plane of the two poles versus the radiation from a slot that is perpendicular to the slot. At UHF frequencies, many slots are placed on the radiating plane, giving large gain figures.

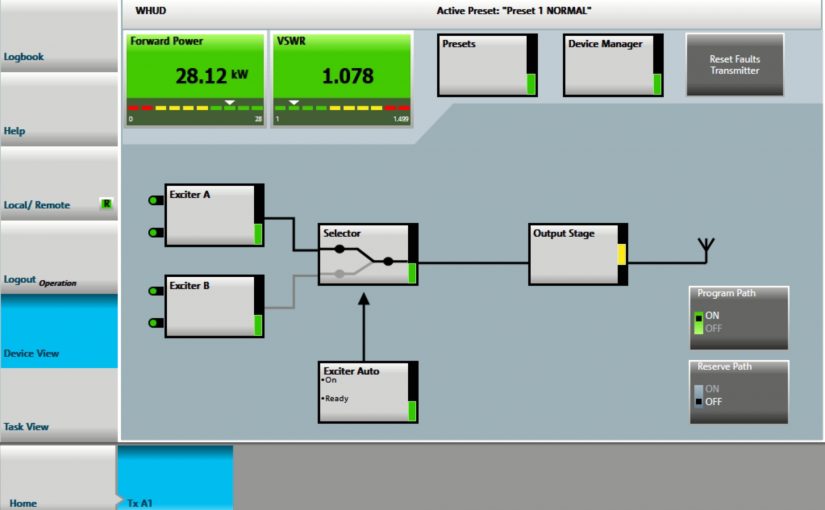

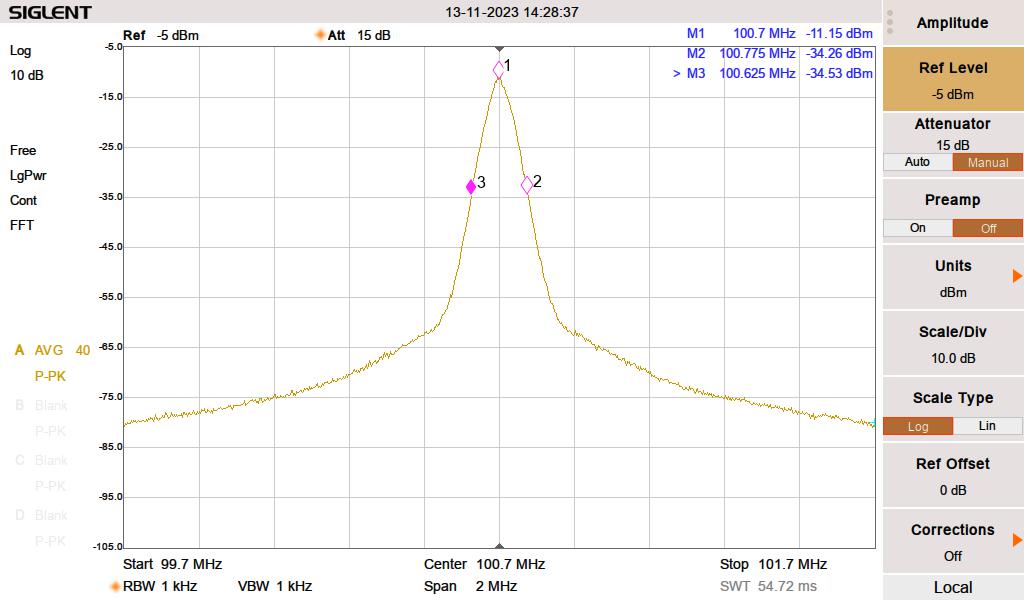

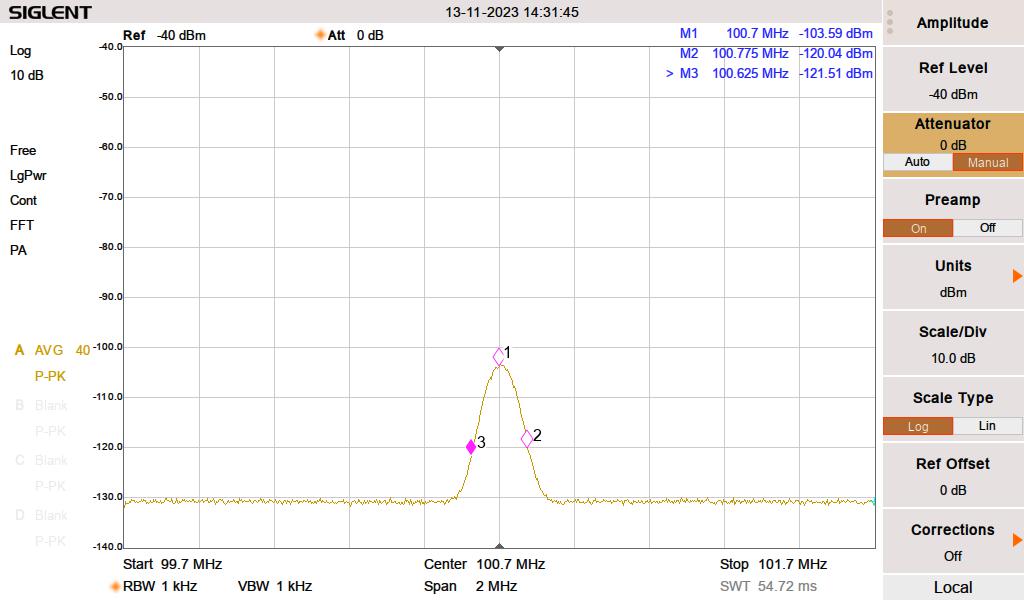

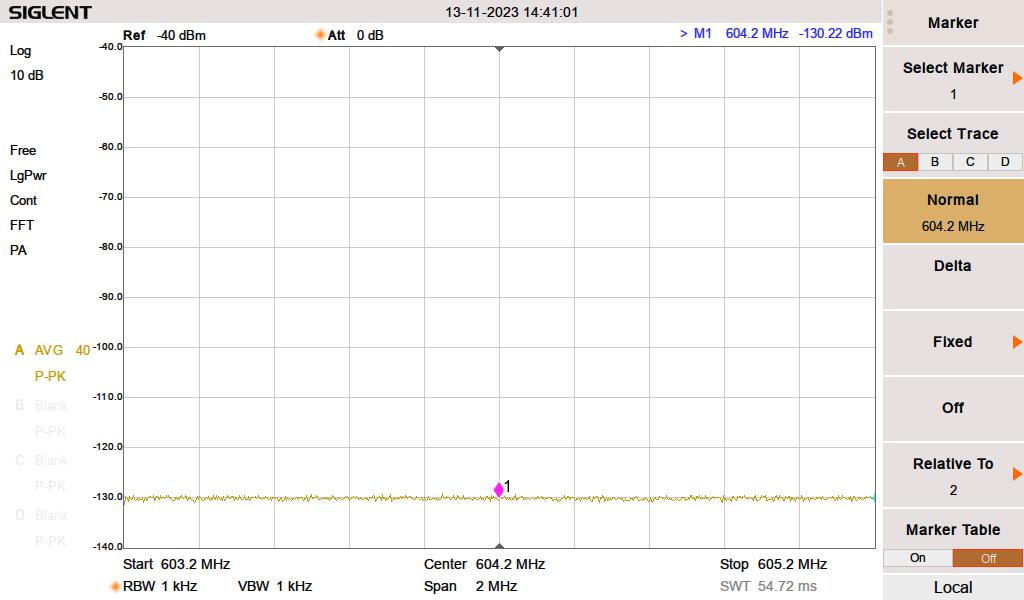

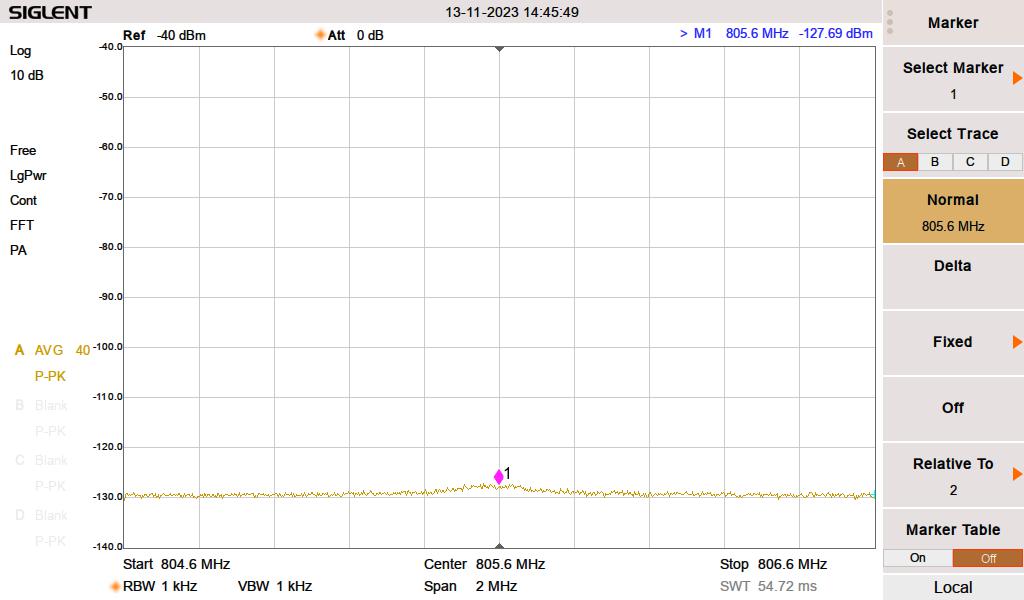

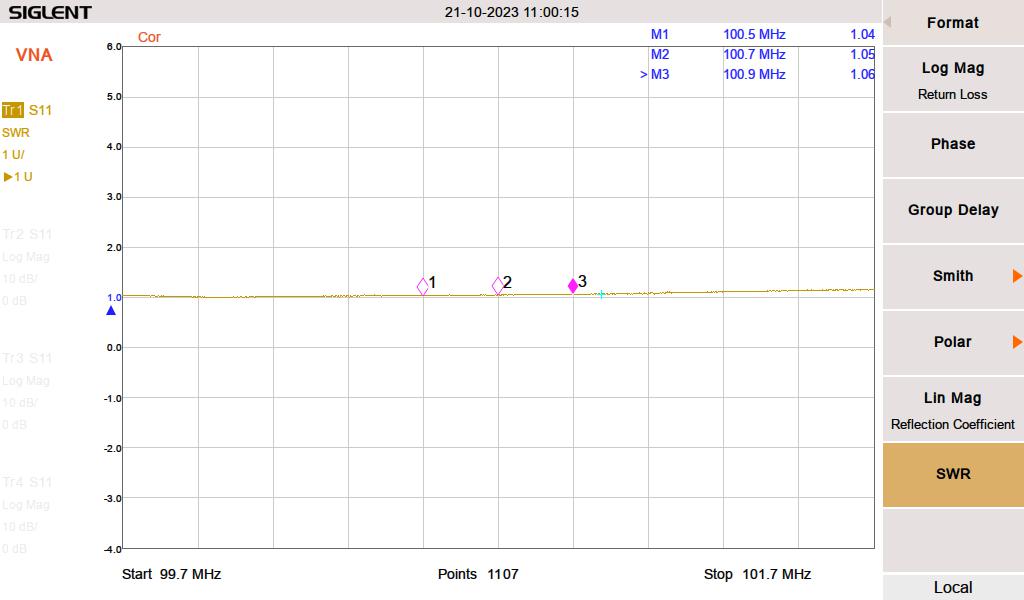

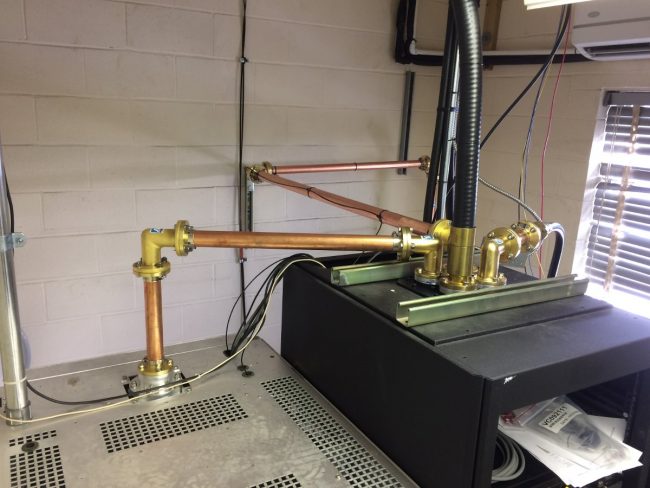

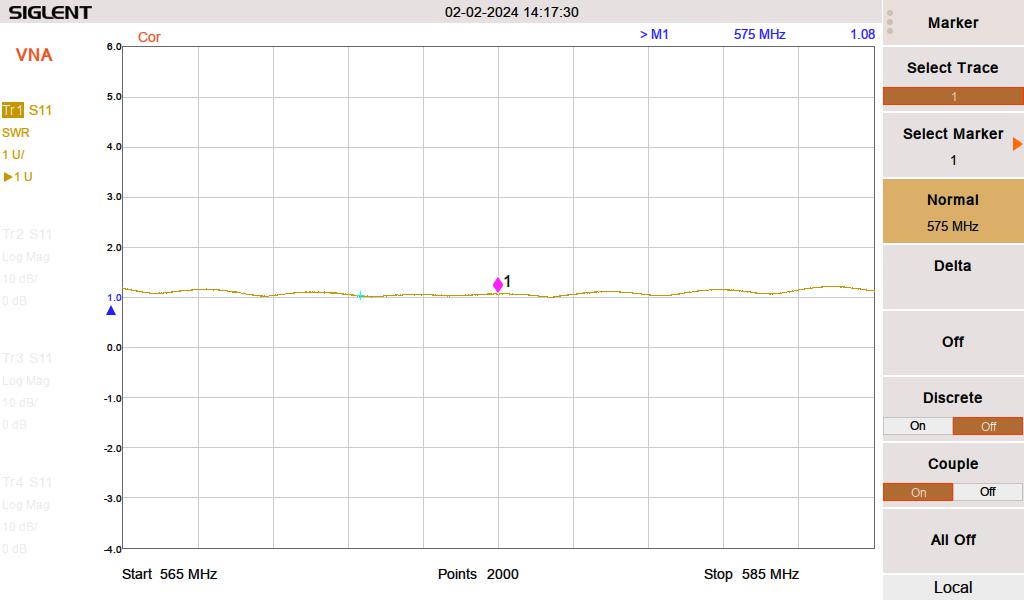

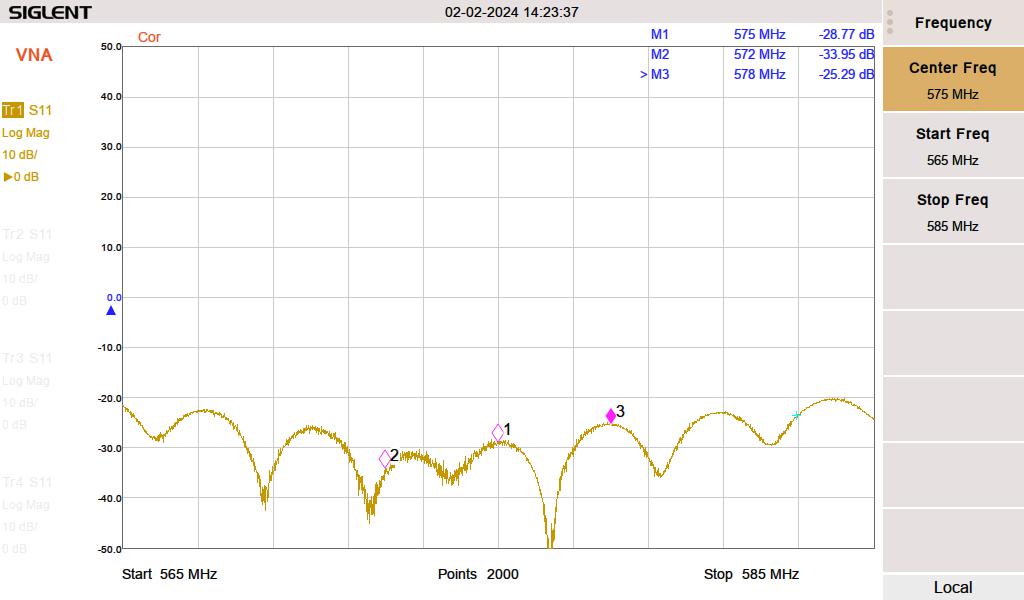

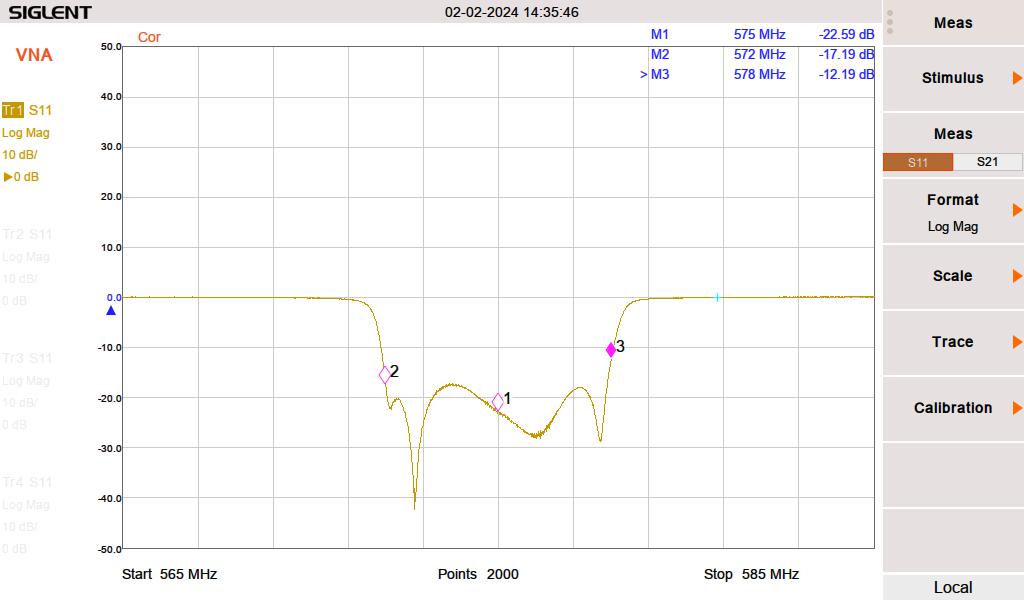

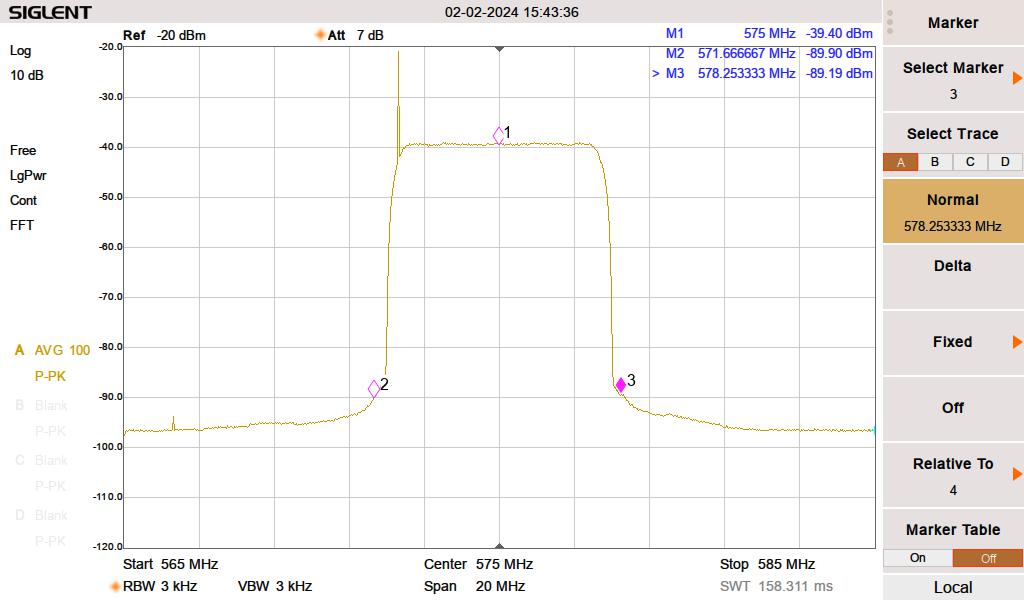

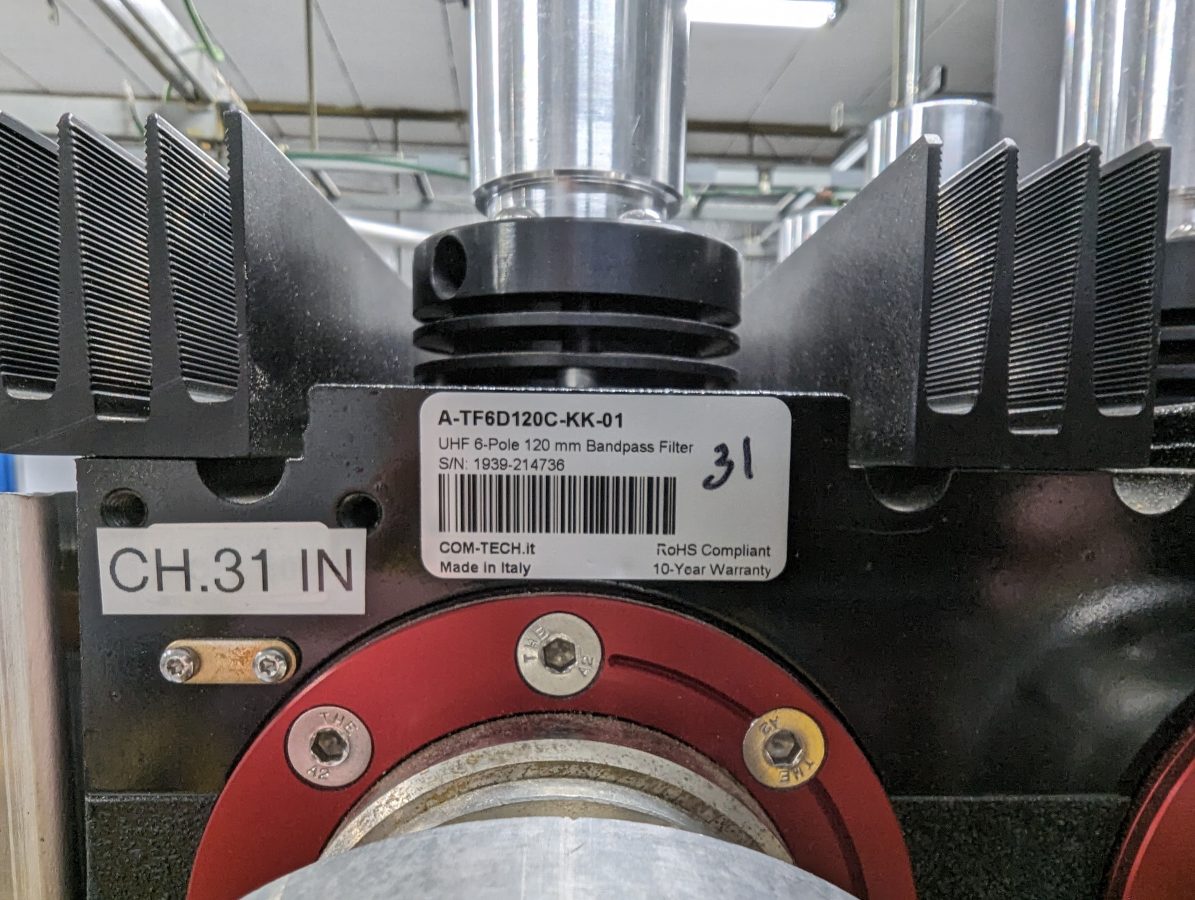

All TV transmitters require a bandpass or mask filter. This is to keep out-of-band emissions out of the tightly packed TV spectrum.

These filters need to attenuate the upper and lower shoulders of the digital carrier by 46dB +/- 3.25 MHz from the center frequency.

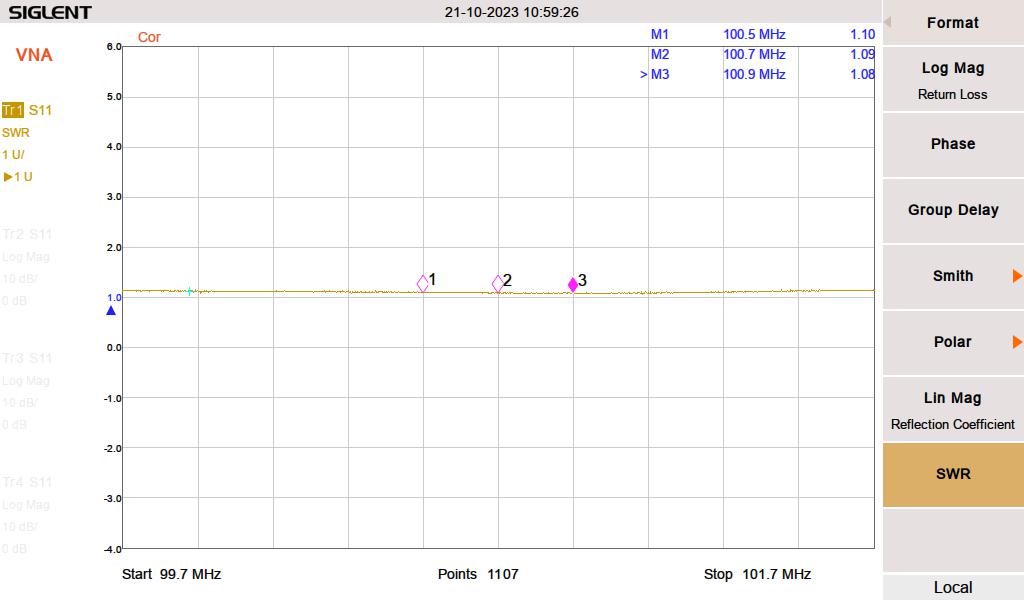

These are fairly straightforward filters, this one has six cavities with plungers that slide in and out to adjust the tuning. I watched one of these get retuned in the field, it takes quite a bit of time and patience to complete and requires a two-port network analyzer.

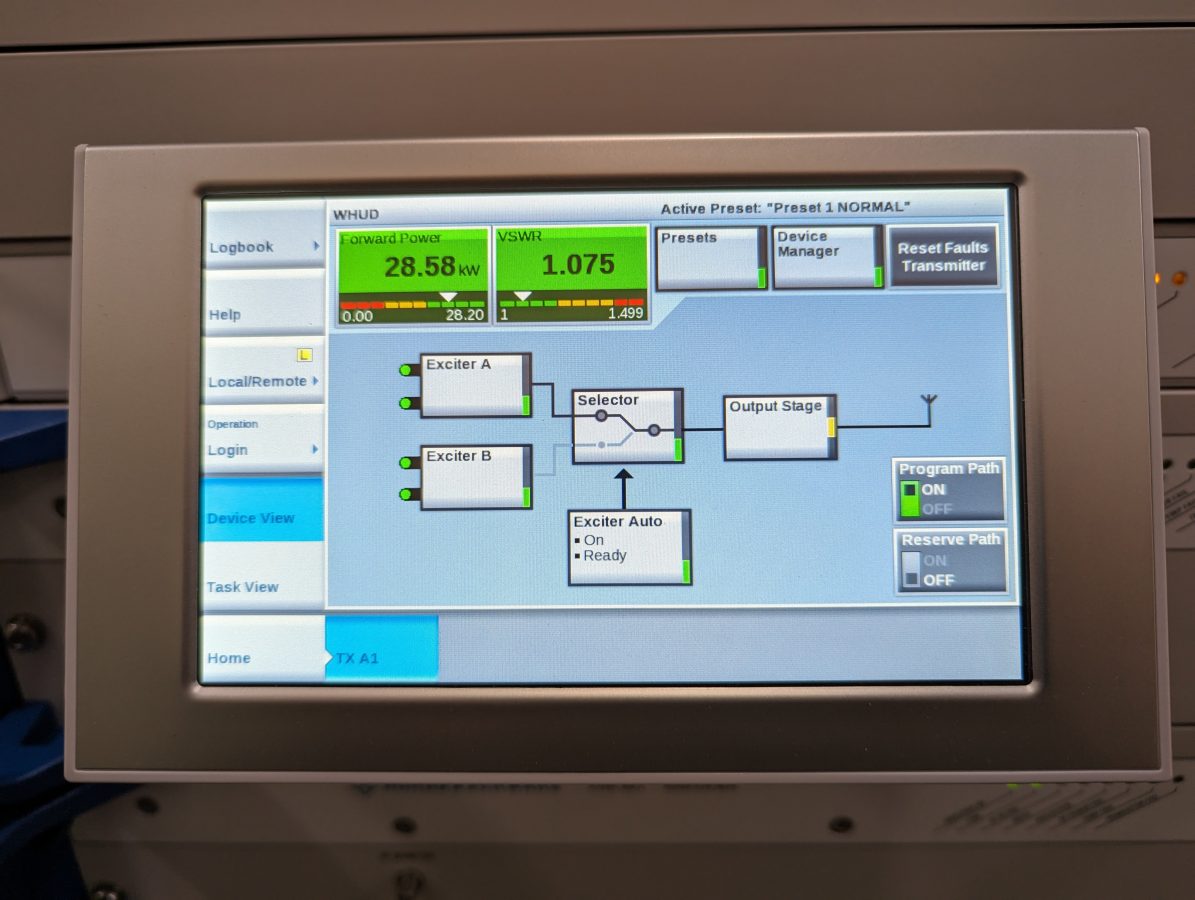

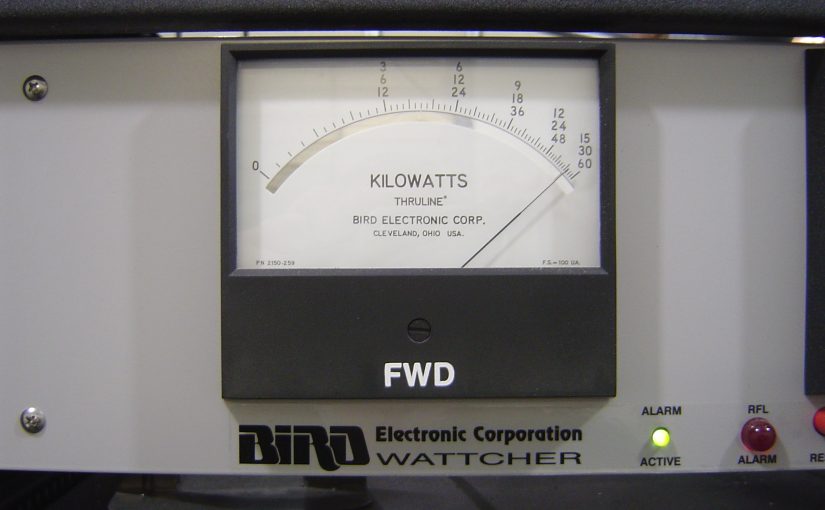

With the TPO of 400 watts, the ERP is 4.7 KW horizontal and 2.35 KW vertical.

So, why bother with all of this? Indeed that is a good question. As cable companies continue to raise their rates (the average cable TV bill is $250 or so) people are looking for alternatives. Cord cutting is a thing and OTA (over-the-air) TV as well as OTT (over-the-top or direct streaming) are popular alternatives.

This station will run France 24 English service and NASA TV to start. Other things you can find on Low Power TV stations; Heartland (mostly country music with some cooking shows mixed in), Retro (old movies), Rewind TV (Old TV shows), Buzzr (old game shows), Court TV, Weather Nation, News Net, etc. More information on OTA TV networks can be found here: https://en.wikipedia.org/wiki/List_of_United_States_over-the-air_television_networks

Rabbit Ears has a good signal search page if you are interested in OTA TV: https://www.rabbitears.info/searchmap.php

More information on Low Power TV (or Local Power TV) and be found here: https://www.lptvba.org/

For a sometimes interesting discussion on cord cutting in general, try this: https://old.reddit.com/r/cordcutters/