This is another SAS console installation for WHUD licensed to Peekskill, NY.

This is another SAS console installation for WHUD licensed to Peekskill, NY.

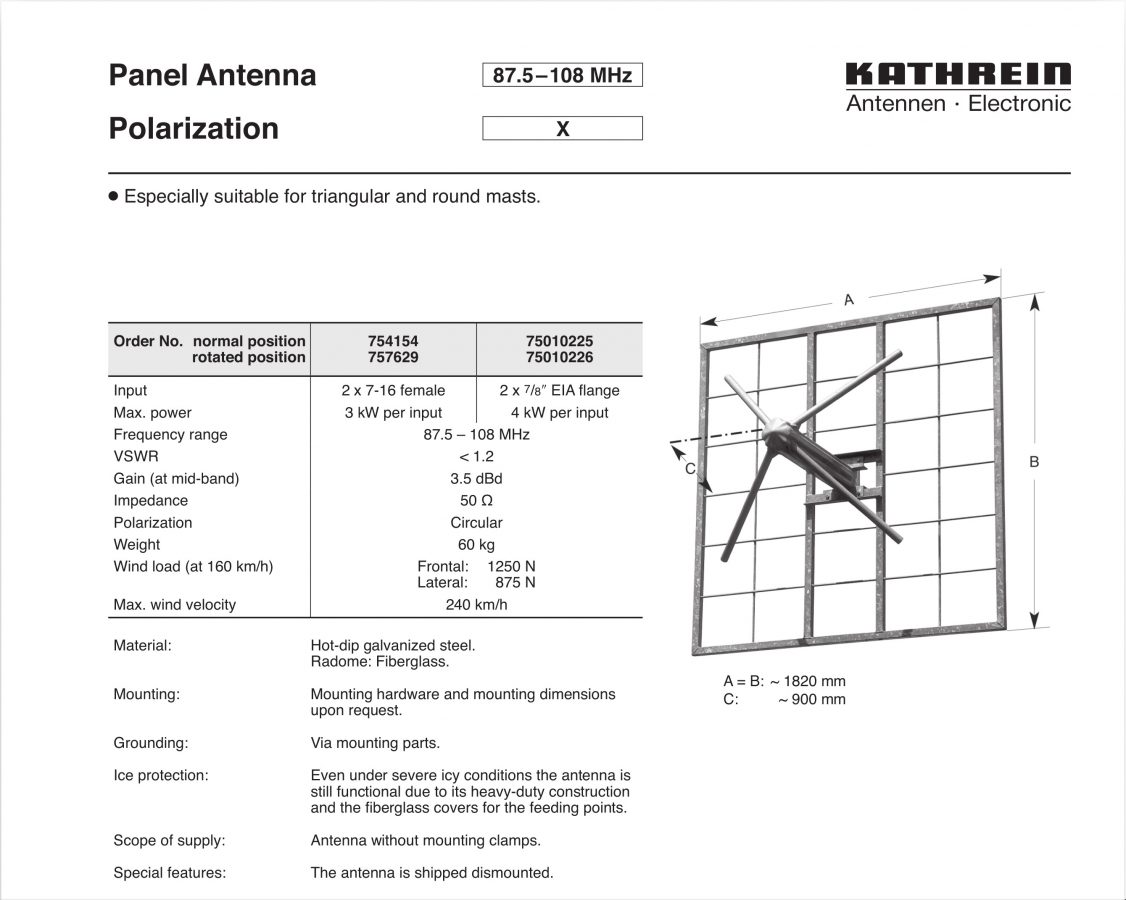

One of our clients needs to move to another transmitter site because their lease is expiring at the old site. We have been working on this for several months now. One of the nice features of this project is the panel antenna.

This is installed in a 2-bay 3-around configuration. I don’t see this particular model in the Kathrein catalog anymore, but there are other cross-polarized panel antennas available from them.

There are many existing services on this tower including two full-power FM stations, a translator, a VHF TV station, numerous cell carriers, etc. Once the installation is done we will have to check carefully for intermodulation.

Winter in the Northeast; there was just enough snow and slush on the access road that the truck could not make it to the top of the hill. This track machine works great. We have added a Polaris Ranger 900 to our inventory (not this machine) for winter access to several of the more difficult transmitter sites. While I do enjoy the occasional walk in the snow, the key word here is occasional.

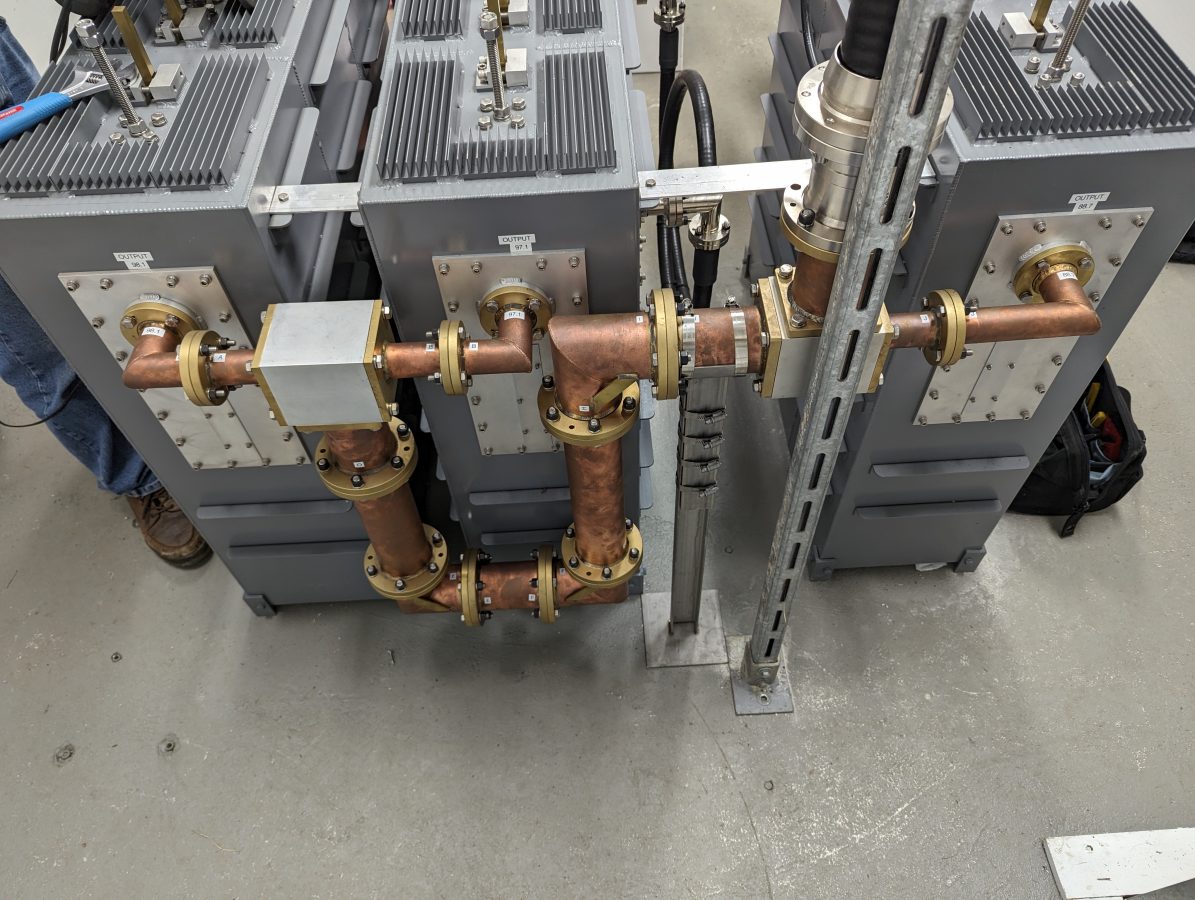

The three stations are combined into the panel antenna with this rather nice American Amplifier Technologies C-IR-3-3-30K-N branch combiner.

The input filters needed a slight adjustment to compensate for the difference between the test load they were tuned to and the actual antenna load they will be running into

Two of the transmitters are Broadcast Electronics STX-10 units. We have had good service from the STX-10 which was installed on Mount Beacon a few years ago.

We are waiting for the Comrex Bric Link III to come back from the factory after their firmware update. They are to be used for the STL. Once they are returned, we should be good to go for site turn-up.

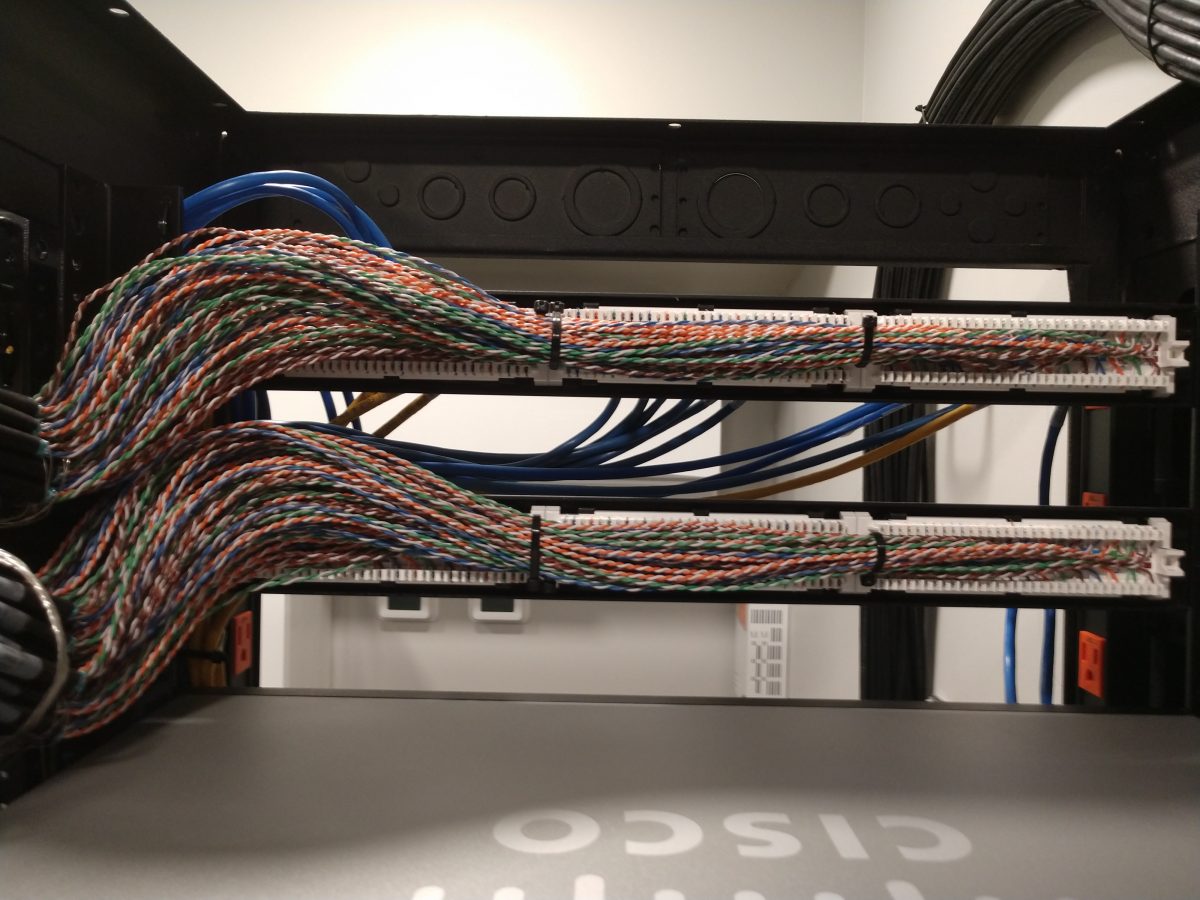

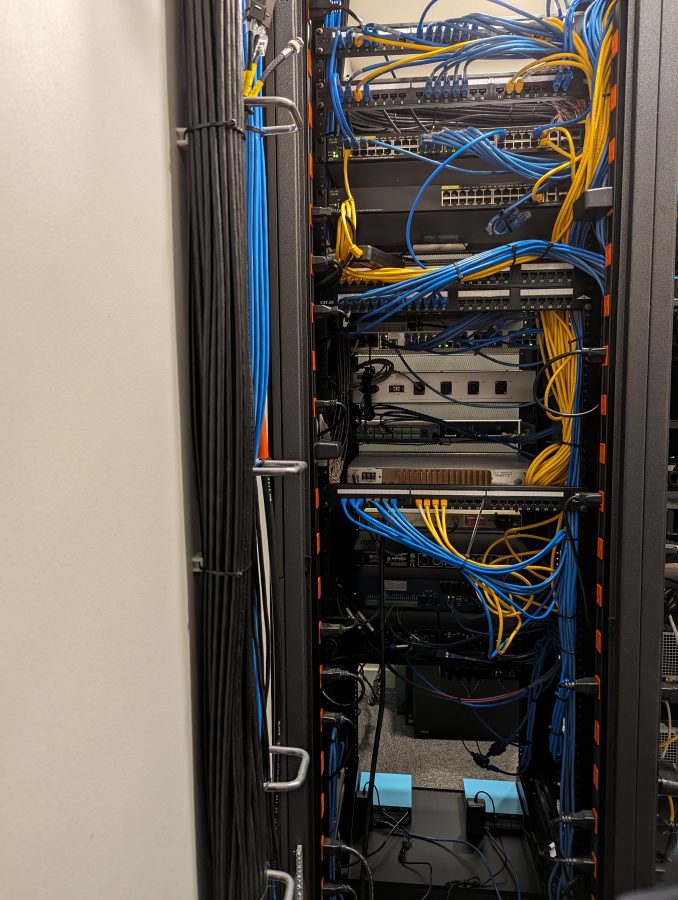

I receive several emails a week from interested readers. One noted that the blog seems to be focused on RF. Yes, that is what I do most, but the company does studio installs as well.

This was from a few years ago.

WDST moved out of their Bearsville studio location into the former Methodist Church in West Hurley.

We installed a new SAS audio router and console system.

Pictures of their old Bearsville studio can be found here:

If folks are interested, I will post some more pictures of more recent studio-build projects.

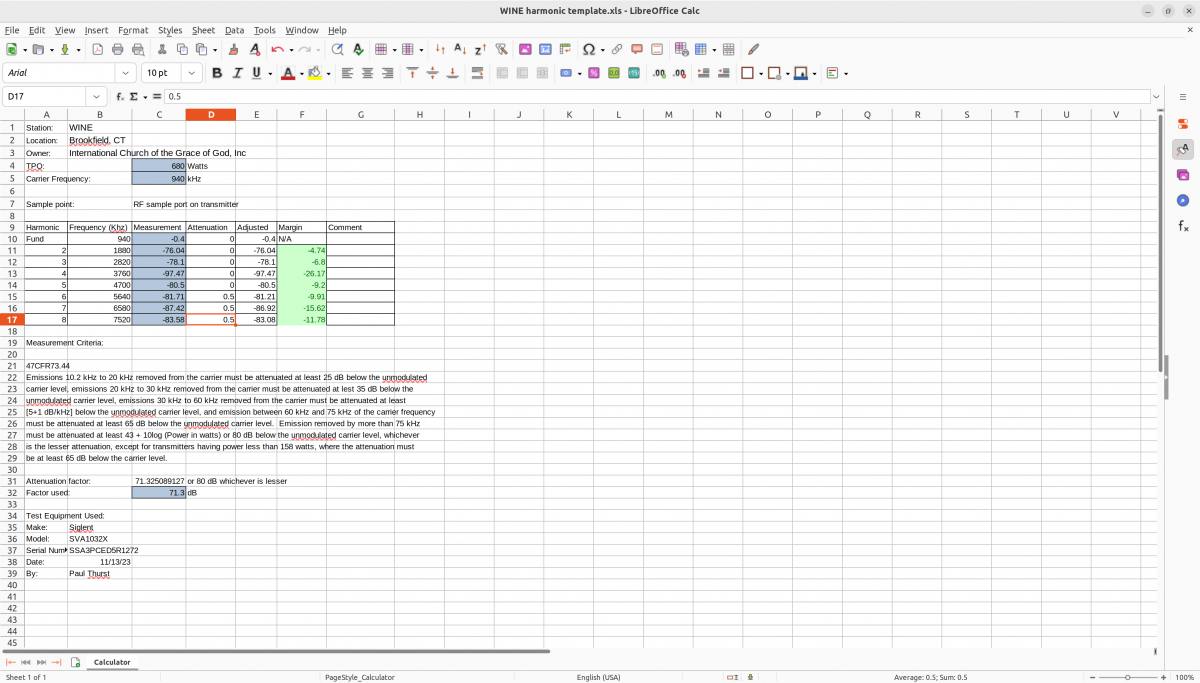

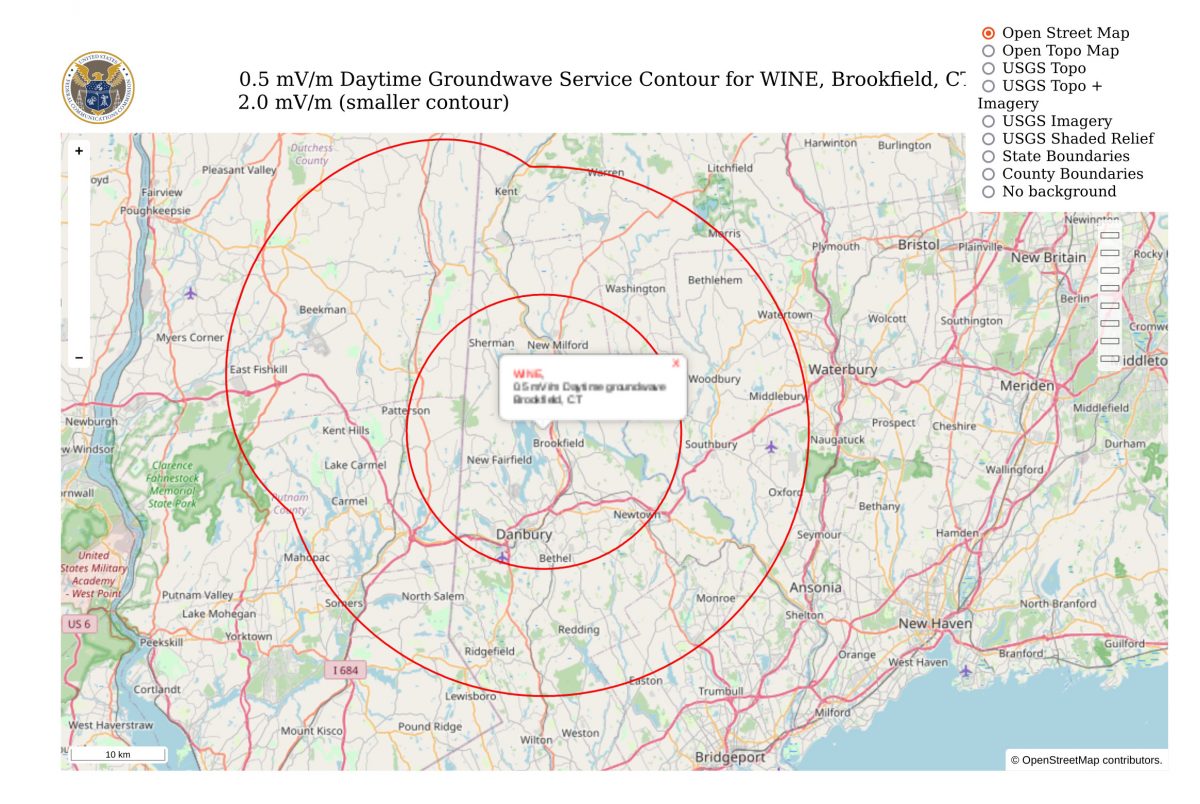

I Finished up this installation of a J-1000 in Brookfield, Connecticut for Nossa Radio. That is a Portuguese broadcaster that owns three other stations in the US.

These Nautels are fairly simple affairs; a controller and two RF amps with incumbent power supplies.

Be sure to install the surge suppressor that comes with the transmitter.

The J-1000 is replacing the 43-year-old Harris MW-1A which will function as a backup. Like all new transmitter installations; some things must be done to complete the job.

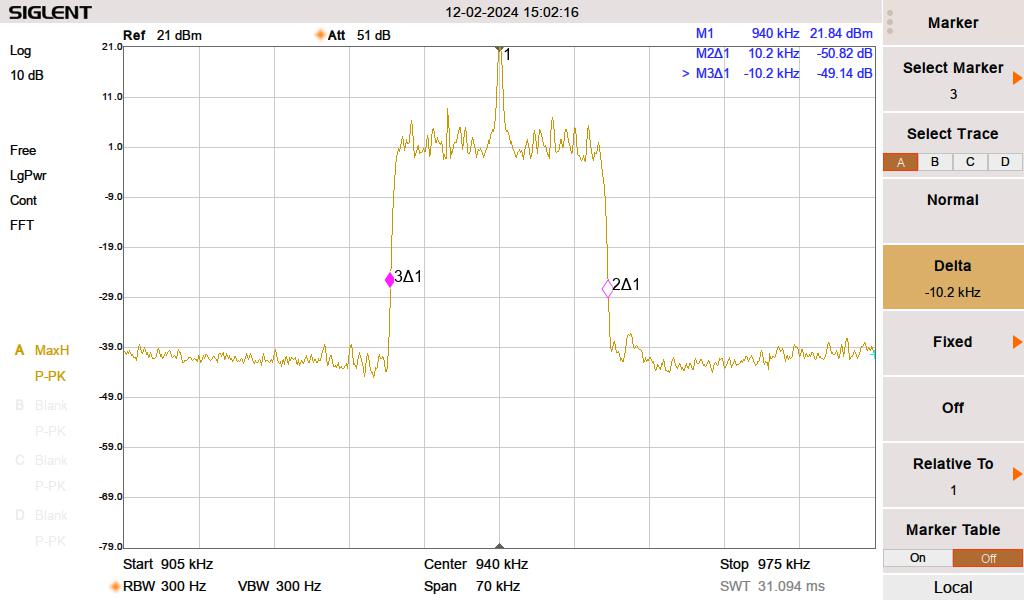

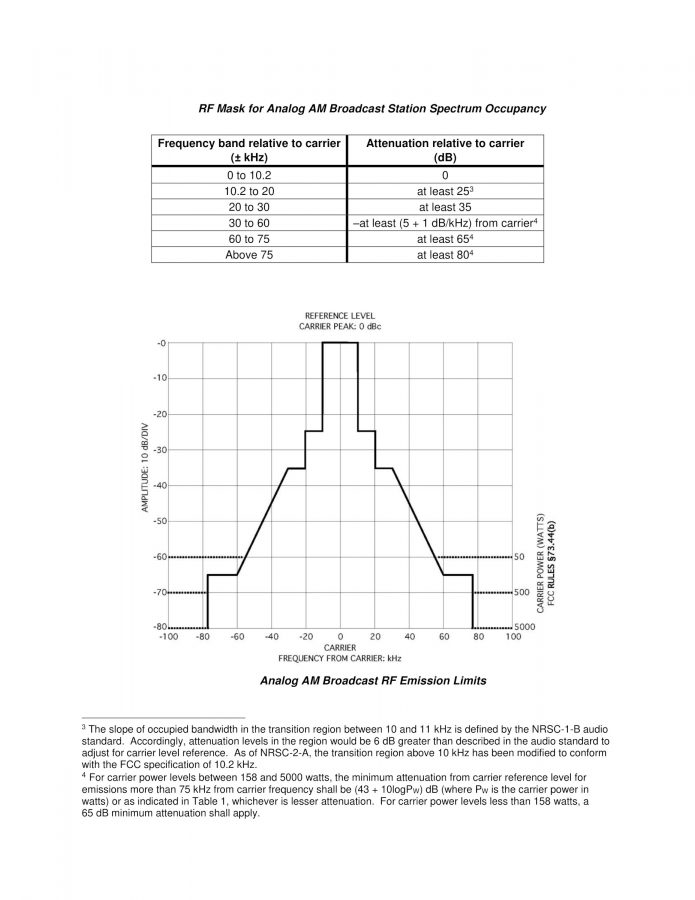

Harmonic measurements out to about the 5th or 6th harmonic need to be documented and compliant with NRSC-2 (AM mask requirements). Although NRSC-2 measurements are required, I don’t see how they can enforce that specification after AM HD radio came into being. Nevertheless, it was measured and passed. With the station carrier power of 680 watts, I used the RF monitor port on the back of the transmitter to make the measurement. Otherwise, I would need to find an empty field somewhere 1 KM away and stand in the middle of it to reduce all of the electrical noise.

The NRSC-2 mask is mainly a function of High-Frequency limitation in the audio processor—certain transmitters, like the aforementioned MW1A did make some contributions to out-of-tolerance measurements.

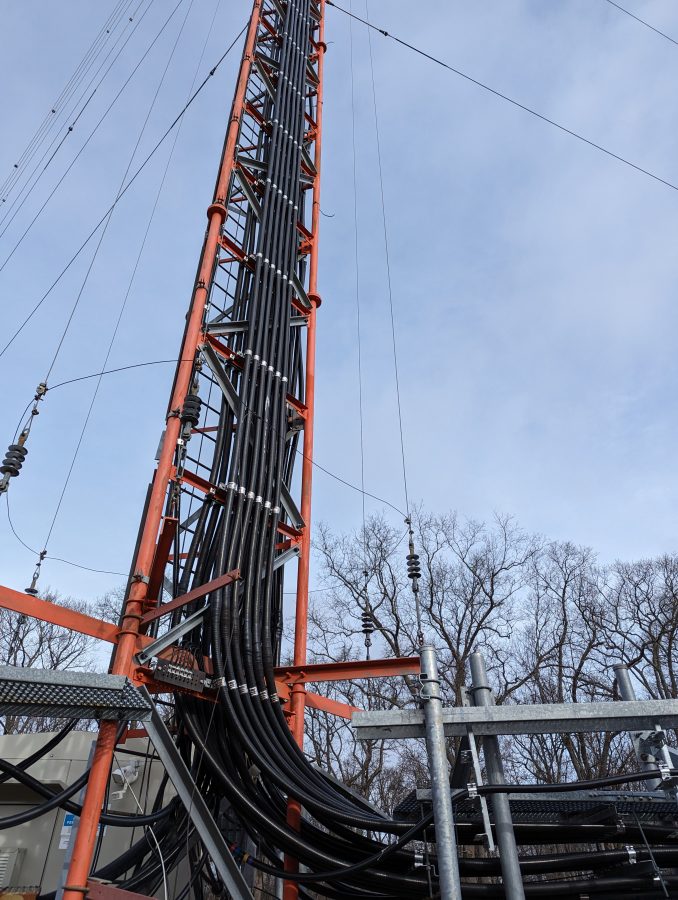

The antenna is a skirted tower that has many other services colocated on it. At the top is WRKI.

Driving away from this site, I would have to agree with the predicted contour map above, at least on the highway. I think it may be a bit different driving around in town.