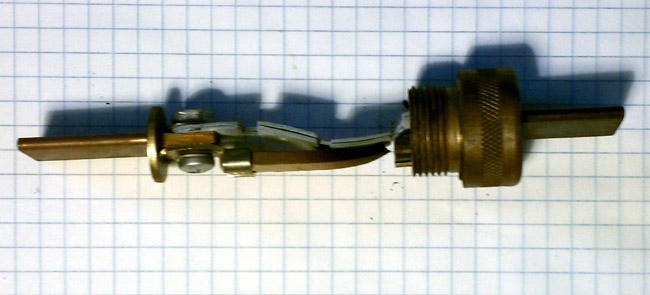

I found this fuse in an old electrical panel that we were removing from the WICC generator shed. This was the original service entrance for the site as it was built in 1932 or so. The generator shed had a manual three pole two position transfer switch, which was fine back when a licensed transmitter engineer was on site whenever the station was on the air. The generator, according to the old records I could find, was an upright 2-cylinder slow-speed engine with a belt-driven generator. They were mounted on concrete pads about 5 feet apart. The motor had a big flywheel that was hand-cranked with the compression off. Once a good head of speed was built up with the hand crank, the compression lever was thrown and the engine would start. Alternatively, the procedure was tried again.

That was all replaced in 1971 when the transmitter site underwent a major upgrade. The old electrical service was bypassed and abandoned in place when a new meter and panel were installed in the transmitter building. The old service seems to have been frozen in time, untouched for forty years.

This fuse is a Kirkman Engineering Company and has a manufacture date stamp of January 1945. It is a replaceable link AKA “renewable” fuse. It has “peak lag” links, which I think would be called “slow blow” today. Peak lag may also indicate a large inductive load, which would lower the power factor. What I find interesting is that someone, once upon a time, placed two 100 amp links in parallel, then crossed the 100 AMP label out and wrote “200” on the fuse body.

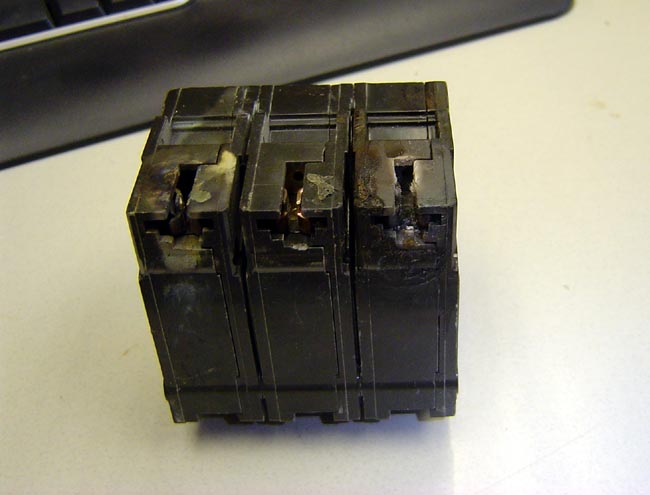

The problem with this setup is that the panel and wiring were all rated for 100 amps. The wiring is #4 copper, and the transfer panel and switch are clearly labeled “100 amp, 3 pole.” It would appear that the finger stock holding the upper blade in place was loose, causing the fuse body to overheat. In fact, it became so heated that the case and the wood fiber holder were charred and missing.

Fortunately, there was never a fire.

The reason why we use properly sized fuses and breakers.