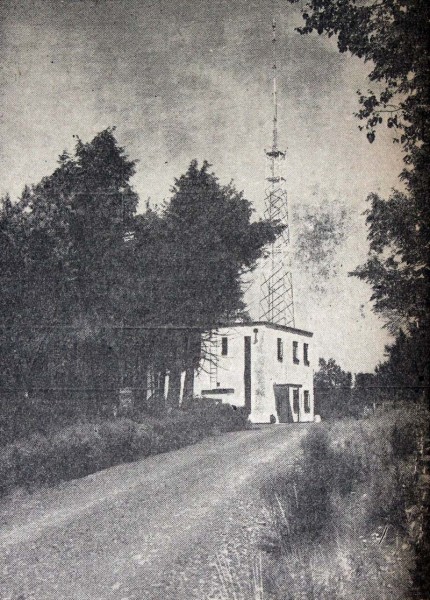

The WICC transmitter site, Pleasure Beach in Bridgeport, has been cut off from normal access since the bridge to the island burned in 1996. Since that time, access has been by boat with a 0.93-mile walk from the dock to the transmitter building.

Last summer, LVI Construction, under contract from the Town of Stratford, put in a temporary road and began removing the burned out cottages. While that road is in place, the radio station has been able to access the site and get many important things accomplished. These include:

- Replacing the vandal damaged top beacon on the South tower

- Removing several decades worth of stored crap, garbage, obsolete and unused equipment

- Repair the electrical service to the building

- Replace the generator transfer switch

- Repair the Sonitrol building alarm

- Replace the old Onan Generator

- Have the power company replace the 3-phase circuit from the point where the underwater cables come ashore to the transmitter building.

All of these projects should greatly improve the reliability of the station. This should make Bill, happy, who appears to have a WICC chip implanted in his brain because every time the carrier is interrupted he posts about it on the radio-info.com website.

The biggest issue with the site was the utility feed from the shore to the transmitter building. The original circuit was installed in 1936 when the station moved to the island. It was old and the poles were all rotting and had horizontal cross arms. Ospreys especially liked the horizontal cross arms as they made good nesting spots. That is, until the nest shorts out one of the phases catches on fire and burns the top of the pole off. This has happened several times over the years causing many hours of off-air time.

United Illuminating, the local utility company, was very cooperative and installed new utility poles, wires, breakers, and transformers, this time with a vertical phase arrangement, which should keep the Ospreys off of them. Additionally, the cottage removal project included installing Osprey nesting poles.

With almost all of the cottages now removed, the area looks much better than before. Actually, it should be a nice nature preserve, and hopefully, the absence of the buildings might reduce the number of vandals in the area. The work is almost done, so the road is about to be taken up. This means we need to wrap up the work out there, so the final push is on.

In the last three weeks, 10 truckloads of junk have been hauled out of the transmitter building and generator shack. Over 1,500 pounds of scrap steel, 640 pounds of insulated wire, 2,000 pounds of particle board furniture, old t-shirts, and hats (something called “Taste of Bridgeport” which, if anyone knows what that was let me know), old propane tanks, batteries, etc. We also managed to fix the fence and gate in front of the building and cut down the overgrown yew bushes and bittersweet vines.

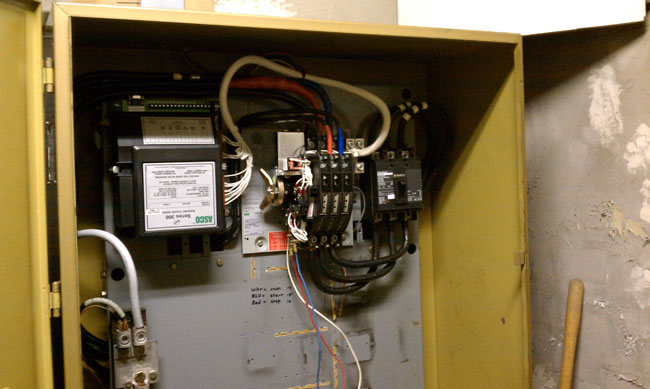

The old Kolher transfer switch was also an issue. There was no place to mount a new switch inside and mounting one outside is out of the question, so the guts from the Kohler switch were removed and replaced with an ASCO unit. This was done in the summer of 2009. The breaker on the right side is the main service disconnect for the building, which was installed in September.

Today, it was time to replace the Onan propane generator. The old generator is an Onan 12JC-4R air-cooled propane unit which was installed on April 4, 1969, at a cost of $1,545.00. For many years, this unit gave reliable service, but it has many, many hours on it and it lacks the fault/self-control circuits needed for remote (read desolate) operation. Several times over the last few years, the generator would run out of gas or the propane tank would freeze up and the starter would crank until it burned out.

It was cold out on the island, with temperatures in the twenties and a bitter west wind blowing right into the generator shack. All of this conspired to make working conditions difficult. Wind chill readings were in the single digits all day long, and in spite of long johns and extra layers, by 3 pm I was shivering and even several hours after coming inside, I still felt cold.

The new generator is a Cummins/Onan 20GGMA which is rated for 20 KW. We used a John Deere bucket tractor to move the generator from the flatbed truck to the generator building, and then push it inside. The old generator wiring to the transfer switch was reused, but a piece of flex was used to connect to the generator instead of the solid conduit. The building fan was also wired up so that it would run whenever the generator was running.

The generator load with all possible things switched on and the transmitter running at full power is about 12,000 watts, but this would mean the air conditioner and tower lights were on during the daytime. More likely, the transmitter will be at low power when the tower lights are on and the AC will be intermittent on/off at night. At full load, this generator uses slightly less than 2 gallons of propane per hour. At half load, I’d estimate that to be 1.4 or so gallons.

HOCON gas came out and connected six 100-pound propane tanks in series, which should prevent tank icing. Propane weighs about 4.11 pounds per gallon, therefore the fuel supply should last about 100 hours, or 4.5 days, give or take. Why 100-pound tanks? Because we will have to shuffle them back and forth between the dock and the generator shed, a journey of about one mile, in a cart. Anything larger would be impossible to deal with. Even so, refilling the propane will be a 2 person job and will likely take all day.

Do not junk the Onan. I have 3 of those and the Studebaker air-cooled engines are very reliable and economical performers. It sounds like the thing was running “balls out” at the 12 kW load, but now with 8 kW of headroom, you should be OK. Surprised that you manifolded a bunch of dinky 100 gallon tanks? Most codes allow them to be close to the building, but I think that you would have been better off with a fenced (alarmed) 1000 gallon tank 20 feet from the building and feeding the genset with “Trac-Pipe” or AGA approved yellow plastic tubing rated for direct burial.

Ah, Studebaker, I was trying to figure out who made that engine. Don’t worry, that generator is going to a good home.

Regarding the fuel tank, I’d prefer a single 1000 gallon tank also, but the station would be unable to fill it once it ran out because vehicle access will be cut off again when the temporary road comes up, likely in a few days time. Thus, portable tanks are required.

I honestly believe that getting a 1000 gallon “dinosaur turd” (as some call them) to the site may have been harder at this time, however, with only a 20 kW genset, the tanks contents would probably last 10 years before re-filling would be needed! And, by then, easy ingress and egress will undoubtedly be accomplished to the island. Fooling around with a hair-brained manifold system of 6 tanks seems “rinky-dink” to me, not to mention the time involved in disconnecting, reconnecting, and carting them back and forth to the island.

Unless things radically change for the better in Bridgeport, I’m of the mind that access to the island will be limited until the lease ends (2036) and/or AM broadcasting ends and the station turns in its license.

I guess the carrier absence alarm for 600 won’t be going off in my monitoring lab anymore (at least for awhile). In my 36+ years of engineering AM and FM stations I would have been embarrassed to have any of the facilities I engineered suffer the amount of downtime WICC was subjected to during 2010. Perhaps this influx of maintenance will indeed prove to make the station more reliable.

Bill, generally speaking, I agree with you: The principle job of a broadcast engineer is to keep the signals on the air.

While working at this site, we had several constraints; the construction company locked the access gate everyday at 3:30pm no matter what, tower climbers are not going to climb at night, tower climbers require the station to be at low power or off the air depending on what they are doing on the tower, the utility company is not going to connect a new electrical service at night and so on. It would have been nice to get the generator installed first, but the powers that be in Atlanta only approved it’s replacement last month. In short, we did the best we could under the circumstances.

Thanks for listening, WICC should be more reliable.

Paul, I certainly understand working under constraints, especially since I have worked more as a contract engineer than being on-staff at a station. Besides, I also enjoyed the freedom to walk away when the corporate bean counters decided what needed attention and what didn’t in spite of solid recommendations.

I worked for a small AM station and while they had an almost non-existent budget by the time I got there they would do the right thing when push came to shove. It was a battle to replace an antique remote control but when they would have problems with it they knew enough to know the investment would pay itself back. Stations that skimp on their own infrastructure will only have it come back to bite them on the backside and I’ve see this occur more than once since I started in the field back the mid-1970’s.

I had tie downs for STL lines on a directional array break loose and it changed the system to the point where the solid state transmitter refused to stay on the air while the tube backup kept on chugging. Since I didn’t own a climbing belt (nor was I insured to do so) we called a tower climber to do the repair work. Yes, low power and I gave them all the time they needed on a Sunday – no locked gates, no bum’s rush. While certainly not ideal we did get the job done and kept things going. The owners even paid the Sunday surcharge to get things corrected instead on hanging on the backup for a prolonged period of time.

I think the rule is to keep the infrastructure up to par and not let it deteriorate to the point where every bump in the road turns into a crisis situation. When I was paid well for my services I would in turn show my allegiance to the stations I worked for. When corporate owners refuse to invest in their physical plants (or their people) things are going to fall apart. Obviously there are some radio groups that aren’t equipped to ride out the economic storm and it shows with the cuts both behind the scenes and in front of the mic.

Now that I’m mentoring high school students with a campus limited AM and FM station I built for a local school district I’m hoping I will be able to train these future engineers and air personalities the right way to do things – too bad the small amount of gear that was donated to build up the station dates back to the 70’s. At least the kids will learn with real broadcast gear, albeit late 20th century!

BTW: Enjoyed a bunch of the blog articles. I’ll have to share some with my students.

Bill, thanks for reading and commenting, I appreciate your experience and efforts to educate those that are interested in broadcasting. Regarding maintenance, you are correct; it is much better to pay for maintenance of existing equipment than to let things go until the station goes off the air. Still, I see this over and over again with every group owner. In this day where there are fewer and fewer owners, it is more difficult to walk away from a station or group without having it come back to bite you somewhere else. Thus is the bane of contract engineering. That is why I and the company I work for is diversifying into other areas.

Paul You asked about the Taste of Bridgeport. This was a summer event that goes back to the mid eights.

It was held at Sea Side Park for a number of years was sponsored and ran by WICC. Booths were sold to local resturants, big food festival along with Entertainment. All the stuff from tickets totee shirts to all electrical lights equipment were provided by WICC and was stored in the generator shack. At one time there was snow fencing stored in the fence area around the transmitter building but was sold off years ago. The Taste of Bridgeport goes back to the day when WICC was own by Tribune Broadcasting.

Nice to see Cumulus invest in a new Generator.

It is not a easy site to maintain due to access.

Did you fine the classic large mic boom on the inside was of the generator shack? that is from WICC channel 43 days

Thanks, Ed. It looked like quite the thing. I can imagine walking around out there on a nice summer evening enjoying an event like that. Sadly, Bridgeport seemed to loose a great recreational area when they couldn’t get their sh*t together and fix or replace the bridge to the island. I did find the mic boom as well as the old insulators from the old wire element, they were moved into the transmitter building.

The new phasor and two BC1H1 transmitters were installed back in 1974. That’s when the horizontal wire that supported the vertical wire as the third tower was taken down. At that time they had lights on the horizontal wire.

it was very dificult to keep the pattern in legal limits

so that’s why they scraped the third wire and upgraded in 74. Back in the day they had a 1kw Raytheon transmitter out there along with a Collins 20V2 1kw transmitter. A Western Electric transmitter which was used to drive a 1kw poweramp. that goes way back. The site was manned up until 74 when the upgrades were installed. Back in the day the Engineer would have the program log and made sure that all the spots ran. He would be the official log keeper,and take the transmitter readings also. How things have changed.

I know the chief that was out there is the 70s lots of history.

Good to see something happening out there. I was at the site quite a few times to help Ed with one thing or another. Considering how many times the propane tanks were vandalized and how hard it will be to refill them, I would have opted for diesel. There was room inside the locked gen shed for a good size tank and carrying out 5 or ten gallons of diesel to add to the tank during routine maintenance visits would make sense to me. You also get more energy from a gallon of diesel as well.

Paul, what type of heating plant heats the building? Or is it not heated. On the subject of diesel generators, it might make sense if the building had an oil burner. However, if not, diesel standby power can be trouble. Fuel oil sours from sitting, and picks up moisture along with fungi over time. And the cold weather starting is not always instantaneous, especially if it is real cold and the plant sits outdoors. A station I used to work for went with standby diesel power when the FM transmitter power was upped to 20 kW, and they have had much trouble compared to the old LPG genset. Personally, I have both diesel and propane standby plants, and the only way you would get me to go diesel is if the fuel could be used in a years time. An oil furnace of say 50,000 BTU/hour fed off the same oil tank probably would be another good way to go.

Once upon a time, the transmitter building had steam heat. I’d imagine by a boiler in the basement. The boiler and all the oil tanks were removed long ago. I think the environmental concerns about fuel storage tanks, especially out there, would be too great. They were talking about a $20,000 fine if we ran over a birds nest, imagine what they would do if we spilled a drop of oil on the ground.

We have a few diesel generators around, mostly in the >100 KW range and in areas where they run often. Those generators do turn their fuel supplies over in 1 years time.

Doesn’t anyone remember Ken Cooper and the days when he was running Top 40 Classical on what was then WICC FM?