This is yet another addition of the “Burned up Sh*t” collection:

It is a breaker from a 5-ton AC compressor. Back in the bad old days when I was the Director of Engineering for a 28-station group Headquartered in Harrisburg, PA, I received a phone call from one of the local engineers. He stated that the studio AC unit compressor had burned out again and the breaker kept tripping. What did I think, asked him. I thought perhaps he should dig a little deeper and determine why the breaker was tripping before throwing another AC compressor at it. When are you coming to town again, he cheerfully inquired.

Okay, I get it.

I started by calling the HVAC company to inquire what had gone wrong with the compressors. Winding shorted to the case for both units was the answer received. It being July and mighty hot out, the various worker bees in the studio were feeling inconvenienced by the sweat in their eyes and dripping on their work, etc. I called the local manager and asked for a hotel room, I’d be up tomorrow. Then I called the HVAC guy back and asked in to meet me at the studio tomorrow afternoon.

Upon arrival the next morning, I found the fifth-floor studios to be hot, as reported. I trip to the roof location proved to be hotter still. I tested the voltages at the compressor unit with a DVM and everything looked good. A trip down to the utility room found the electrical panel in reasonable shape. Then the local engineering guy chimed in, “Oh yeah, I forgot to tell you, the breaker hums and gets hot when the compressor is on.”

It’s always that little bit of missing information…

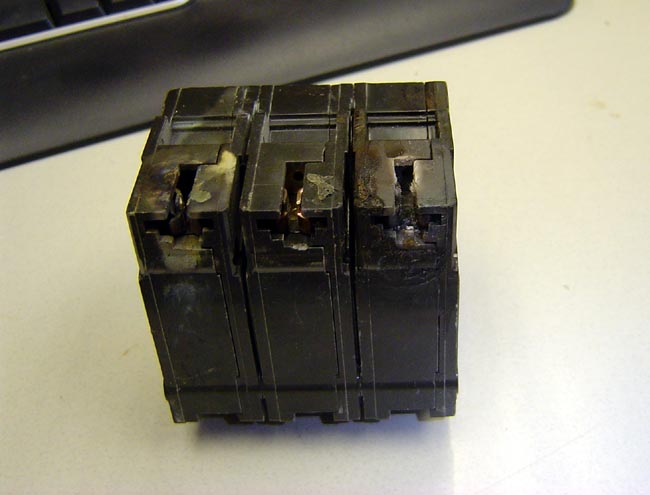

I took the breaker out and sure enough, the fingers were all arched and nasty-looking.

I replaced the breaker, the HVAC guy showed up, with a new compressor and the studios began to cool off around 3 p.m.

Since then, I have specified Square D QO bolt-on breakers for new installations, especially for heavy loads like AC units, transmitters, and so on. They are a little more expensive, but in light of two AC compressors, the unscheduled trip out of town, and the grumbling staff, it is better to pay upfront for better equipment than to put up with preventable outages.

That, my friend, is the money quote of the day! And the fact that it is backed up with an actual incident? Well, this story should be required reading for every manager everywhere. “No, we don’t need that. It’s too expensive.”

Until it’s too late. Then all of a sudden, the checkbook opens up. It just has to open wider than if you had just opened it enough to begin with. Never enough to do it right; always enough to fix it (even though it costs more).

As the saying goes, “Pay me now, or pay me later…”

Unfortunately, QO breakers will not work as a replacement in your existing panel! And, I have to disagree with you on your choice of “QO”. First, the “QO” clamp is rounded and doesn’t really grip the bus well in a standard “QO” panelboard. What you really need is a “bolt-in” breaker, and if you like the French so much, then a “QOB” type “bolt-in” will make a tight low resistance contact to the bus. Our experience with “QO” has been a lot of mechanical failures with this breaker series, and since they are supposedly warranteed for life, you can get a new one on exchange after some haggling. The classic 1 inch breaker that you show is either a GE, ITE, Bryant, or possibly General Switch brand. We’ve evaluated them all, and have the least problems with Cutler Hammer (now owned by Eaton) and Siemens (formerly ITE). The other thing to be aware of is the bus material. Many residential or light commercial panels have an aluminum bus, which is not suited to continuous heavy loads found in industrial applications. Now, if you care to study the designs of circuit breakers like I have, Cutler Hammer copied the 1/2 inch wide “QO” design and made it better by attaching a retaining clip on the jaws to keep high tension on the bus contact. If you like 1/2 inch breakers, the “CH” series now made by Eaton has been a trouble-free breaker. We have never had a problem with them.

John, Actually you agreed with me.

OK, but I wouldn’t necessarily blame the GE THQL breakers, as they actually make a better contact to the bus blade than the standard “QO”. GE makes “bolt-in” types in a 1 inch configuration that I believe run a little cooler than the 1/2 inch types because of greater mass. However, I am not a big fan of Schneider Electric, the French company with a German name! Their prices are the highest, and in my opinion after years of experience, we have had to return many for mechanical problems. In a 1/2 inch breaker, checkout the Cutler Hammer type “CH” and compare them closely with the “QO”. You might just see my point.