Radio studios involve quite a bit of wiring. Runs between the console and equipment are pretty straightforward, from whatever the connector required for the equipment to whatever the connector required for the console. When it comes to trunk runs between the rack room and the studio, however, some type of terminating block is required.

This particular cabling installation is for low-level signaling, contact closures, and the like. It uses a Belden cable with 37 un-twisted wires which do not follow the standard Western Electric color code. The color code can be found here. If it were audio or data, the wires would be terminated differently. That color code can be found here. For more information on color codes and pinouts, see this post.

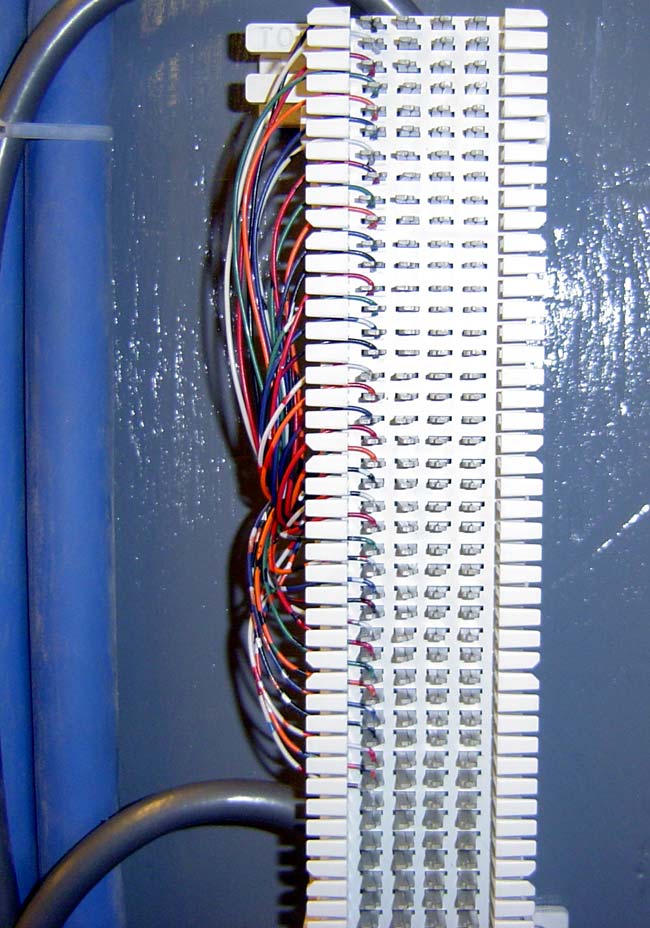

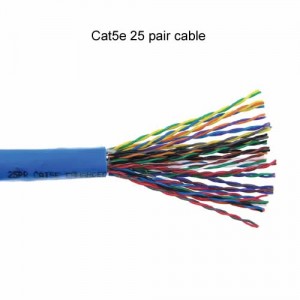

Many engineers use the venerable 66 block or M block insulation displacement termination. These terminal blocks were designed by ATT to terminate 25 pair 22 through 26 gauge solid wire. The original design was rated for category 3 (16 MHz or 10 mb/s) communications standards. Newer designs are category 5 or 5e compliant (350 MHz or 100 mb/s). Notice the part about the solid wire. Most audio wire is stranded and as such, the metal fingers on a 66 block will cause stranded wire to spread out losing contact with the terminating finger. This causes intermittent connections and audio dropouts, which I have experienced often (before I knew better, I used 66 blocks when building studios). The way to cure audio dropouts on a 66 block is to heat the termination fingers with a soldering iron. This melts the wire insulation and gets it out of the way. In the long run, it is better to use more suitable terminations.

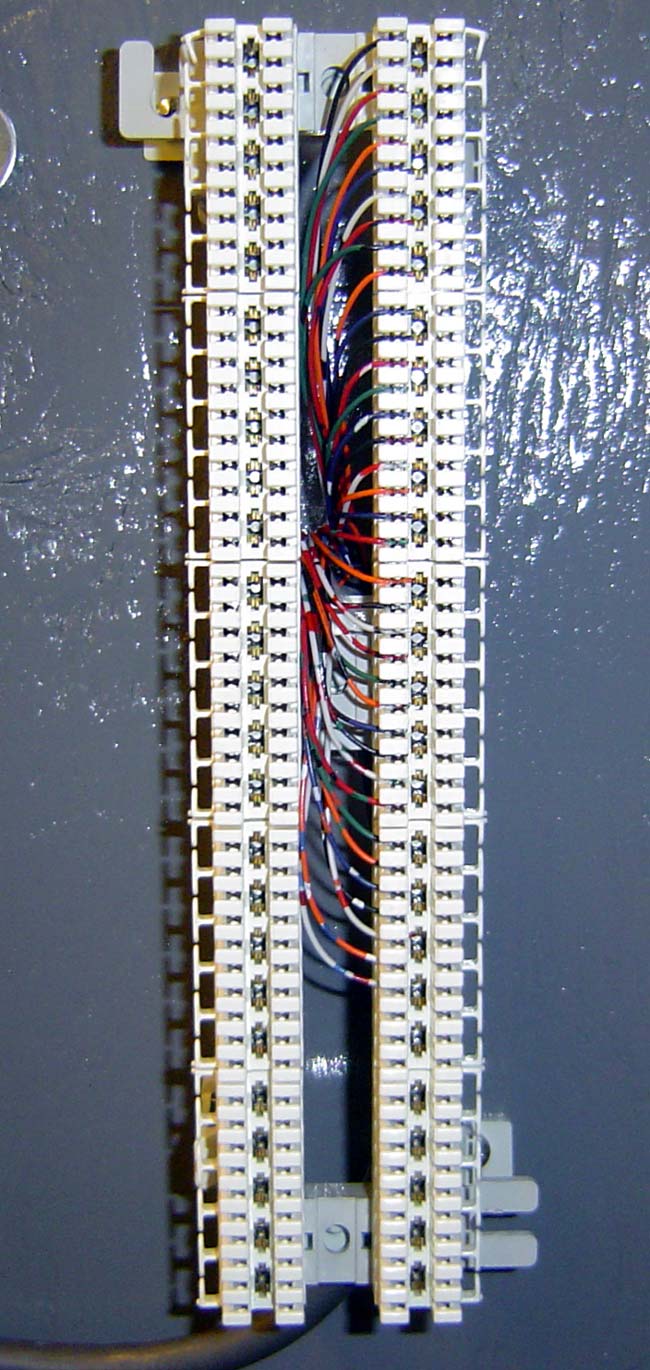

The 110 block is an updated version of the punch block for high-speed networks. it is also designed for 22 through 26 gauge solid wire. This is the termination used on category 5, 5e, 6 patch panels and RJ-45 jacks. They are also formed into block-type terminations the size of small 66 blocks. The 110 block is designed for 500 MHz (1 gb/s) or greater bandwidth. Krone makes a version of a 110 block called LSA-PLUS which is an acronym that stands for: Lötfrei, Schraubfrei, Abisolierfrei, Preiswert, Leicht zu handhaben, Universell anwendbar, Sicher und schnell. This translates to: no solder, no use of screws, no insulation removal, cost-effective, easy to use, universal application, secure and fast. Unlike a standard 110 block, the Krone block is designed for solid or stranded wire. 110 blocks are acceptable for use with AES/EBU digital audio at sample rates greater than 268 KHz as well as gigabit networks and analog audio.

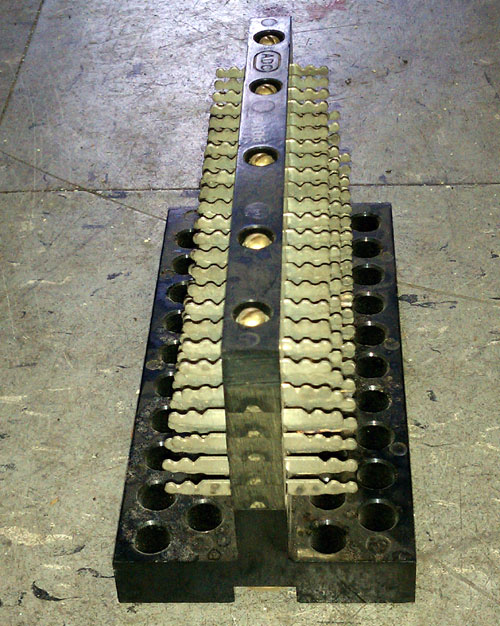

In very old installations, I have seen Christmas trees. This is a wire wrap system where wires are wrapped around metal fingers that form the shape of a pine tree, hence the name. They were very popular in the fifties and sixties and only work with solid wire. It is also time-consuming work and requires special tools and skills. Wire wrapping is a bit of a lost art.

Screw barrier strips have been used to terminate audio cables from time to time. I wouldn’t consider this method because it is too time-consuming, takes up too much space, and is difficult to label.

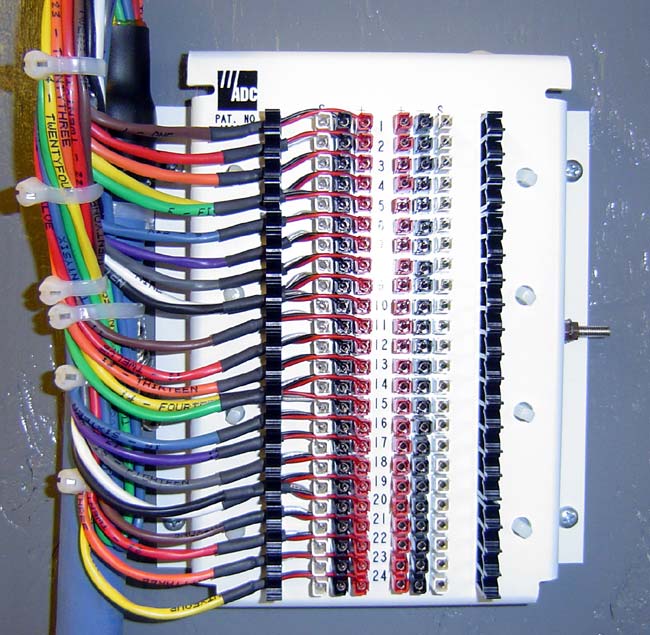

ADC makes a good termination block called ICON (Integrated Cable Organization Network) which uses QCP (Quick Connect Panel) connectors. the connectors are small square devices that are insulation displacement termination (like 66 and 110 blocks) but require a special tool to “punch down.” This particular type of connector is well suited for stranded wire from 22 through 26 AWG. QCP connectors are also used on some of ADC’s patch panels and other audio products. Like any other termination technology, they are only as good as the person punching down the wires. QCP connections are small high-density devices, I have seen them get mangled by someone in a hurry who got his punch-down tool across two of the terminals by accident. ICON blocks can be used for digital audio, however, they do not maintain the 110 ohms impedance of most digital-type audio cables (neither do XLR connectors, by the way). This can lead to some return loss, which on longer cable runs can cause problems.

Radio systems prefer RJ-45 connectors with Category 5 cable, something they call Studio Hub. These are 110 blocks as noted above, but designed primarily for computer networks. Radio Systems discovered that the impedance of most audio cables is very close to that of computer network cables, audio cable is designed for 110-ohm impedance vs. computer network cable which is designed for 100-ohm impedance. Therefore, RJ-45 connectors and shielded or unshielded twisted pair work well with balanced professional audio, either analog or digital.

For analog audio wires, ICON blocks seem to be the best, most secure high-density termination system. In all my years of using them, I have never had a connection go bad. 110 block and other category 5 or 5e systems also work well. For digital audio, Krone blocks or 110 blocks need to be used in order to maintain the full bandwidth characteristics of the cable being used. Using appropriate cable and or terminations in digital audio circuits often leads to impedance mismatches and high return losses in the system.

When I started at AM1590, a double-plug patch panel jack field was pretty much standard which had all soldered connections. ADC also made a bulkhead feed-thru termination which was more convenient but required additional double wiring to the actual patch panel jack field. Things started changing in the ’70’s with more of a telephone technology slant on terminations. The old way worked fine, but many of the new crowd seemed to dislike the patch panels (or didn’t understand them). I have no problem with Bell 66, and with Belden 8450 (solid), a neat job ensues. We always grounded the shields at one end, so this configuration is still around at some stations. Bell 110 in my opinion is a throwback and a flaky connector, I will never use it. Modular RJ45 type is the “in thing” these days, but they have their problems also. The locking tab can be easily be broken off when pulling cables through ducts, and might be just fine for Ethernet, but audio is something else. I am one to stay with “tried and true” techniques; call me old fashioned, I don’t care! Getting good electrical connections, and I mean GOOD connections has always had a source of problems. Fretting Corrosion, dis-similar metals, and cleanliness, are troublemakers unless the joint is properly soldered. Gold flashed connection points will alleviate many of these connection problems, but with today’s Gold market, it is probably way too expensive to be practical.

FYI, Lots of inaccuracies …

The 66 block pictured (aside form having a stranded cable attached in an incorrect color sequence) was invented long before any thought of running Ethernet through them. Long before the “category” (originally called “level”)rating system was invented by Anixter Bros. Co.

An “M block” (correctly, 66M) is not a synonym for “66 block”. 66 block come in numerous styles, one of which is the 66M1-50 pictured, another “66B25”.

Also, the image of the Christmas tree block incorrectly calls it a wire wrap, it’s actually solder terminated. Wire wrap termals are square in cross section.

@Steve,

Regarding the color code on the 66 block; There are lots of different color codes, none are more correct than the other. That happens to be the color code I downloaded from the Belden site, supplier of the cable attached. This is not a category rated block and those are not ethernet terminations, they are closures and low level DC signaling.

As far as the naming conventions; I am sure you are probably right, however, most people recognize 66 block, thus it is the name I used. It is a bit hair splitting accuracy, like arguing the difference between “car” and “automobile.”

Regarding the Christmas tree, you are correct, that is a solder terminal, not a wire wrap.

Lots of different color codes, yes, but the former Bell System Code is the one used most frequently for telecommunications.

Most cable manufacturers use is as well. In the telephone industry we used “conventions” as well as standards.

One of the conventions was Ring is Color, Tip is Tracer.

Pairs count: Blue, Orange, Green, Brown, Slate. Tracers and Binders count: White, Red, Black, Yellow, Violet

Here is a good reference site:

Don Telecommunications Engineer (Retired) 1966-2006

Two comments on this paragraph above – “In very old installations, I have seen christmas trees. This is a wire wrap system where wires are wrapped around metal fingers that form the shape of a pine tree, hence the name. They were very popular in the fifties and sixties and only work with solid wire. It is also time consuming work and requires special tools and skills. Wire wrapping is a bit of a lost art.”

1) We were able to wrap these with stranded wire but had to solder the connection after the wrapping.

2) It doesn’t require specialized tools. Plain-jane wire stripper and then manually wrap the wire around the post, then clip. By contrast 66 and 110 blocks does need specialized tools!

An additional few comments about the venerable “Christmas Tree” block . . . (also called by some “porcupines” and “hedgehogs” . . .)

I think that they too were a Telco thing, something used in the COs before the 66 blocks. They can be used with stranded wire but were designed for solid (stranded should be tinned before wrapping around the posts, or you can use Scotchloc connectors if you feel lucky). Connections to them should ALWAYS be soldered (unless using Scotchlocs) but I have seen some that weren’t and lasted 20+ years without an issue (hey, sometimes you miss one or two posts with the iron at the end of the day). They were part of a termination system that relied on enamel-impregnated cloth insulated solid wire. Using the correct wire (sometimes referred to as BBE, or Belden Braided Enamel, at least the cross-connect stuff; standard Telco switchboard wire) you could make pretty good time after your hands calloused up. Just take a pair of needle nose (chain nose) pliers and crush the insulation back to the point you want a clean wire and it will easily flake off. A couple of wraps around the post, starting towards the rear/bottom, is all it takes. Then a sharp tug with the pliers in the right direction and the wire breaks neatly at the post. And then on to the next connection . . . Then solder them all down. Makes a very neat and reliable job, just like lacing cord; but I don’t miss either ;>)

Hello, I wonder if this is still being monitored. I am a motorcyclist and researching the replacement of electrical connectors. The vendor (Honda in this case) only sells the entire wiring harness. There are no parts listed for the connectors, thus we must become experts ourselves in sourcing the parts.

While researching I discovered the connector is called a Type B 110 block. I added a url below (urls allowed here? I guess I will find out.)

Reading above there is a reference to 110 Ohms but this page is not succinct. Is the 110 named for the wiring impedance for the punch block?

The same-named electrical connector I am looking for has .110″ pins.

So is the naming between the punch down block and this electrical connector a coincidence, or did the electrical connection derive from the punch down block? The electrical connector does look like termination caps I found that sometimes insert into the punch down block.

http://www.easternbeaver.com/Main/Elec__Products/Connectors/110_Connectors/110_connectors.html

Thanks!

John,

I am going to say coincidence.

I believe that 110 in the IDC blocks that we use were came from their Western Electric or Bell part number. Where that came from, I have no idea but assume that it is just a number that someone stuck in a catalog… There are/were 66 and 88 blocks as well.

The connectors that you are referencing appear to be named 110 due to their physical size. I doubt that they are 110 ohm impedance.

” John

December 9, 2015 at 9:54 am

Hello, I wonder if this is still being monitored. I am a motorcyclist and researching the replacement of electrical connectors. The vendor (Honda in this case) only sells the entire wiring harness. There are no parts listed for the connectors, thus we must become experts ourselves in sourcing the parts.

While researching I discovered the connector is called a Type B 110 block.”

John,

I ride a ST-1300ABS …. Which connector failed ? I’m guessing alternator .

Don W4DNR Huntsville, Alabama

Don;

Interesting it’s at the alternator on yours. The CBR900rr fails at the regulator. Specifically the ground connection which runs hot enough to damage the plastic housing. Apparently electrical systems are not Honda’s thing 🙂

Thanks for the replies!

Kevin see this:

http://www.tek-tips.com/viewthread.cfm?qid=1400511

Without providing detail the poster suggests that the part number is derived from the config. Though it seems anyone old enough to know the details of these block configs has moved onto the next life? But it is looking like the Honda connectors are proprietary Sumitomo motorcycle connectors and are unrelated to these telco blocks.

Don, the issue is with the VFR800 but may apply to your bike. The owner is looking for the connectors on the brake light. Actually it has not failed but he wants to properly insert an accessory without tapping the wires. It is this connector that I discovered has a “110” moniker.

Chuck, for sure Honda takes massive criticism for electrical system quality. However, for everyone complaining about a fried regulator or stator there are people who ride, say VFRs, 70,000 miles on the original charging equipment. How can the issue be a quality issue, but some never have a problem? I suspect the magic is preventive maintenance, and quickly identifying shorts. In your example, I bet this ground block doesn’t fry on year 1 or two, right? If it did Honda would have to replace it. But after 5-10 years of use, the connections and ground blocks require cleaning, removing the built-up corrosion. How many bikers do you know who refresh the switches and connections proactively? I think most of the vehicle buying public rides their vehicle until it dies, then they fix it or sell it, rather than being proactive. For these reasons I think the finger pointing at the mfr. is a little unfair.