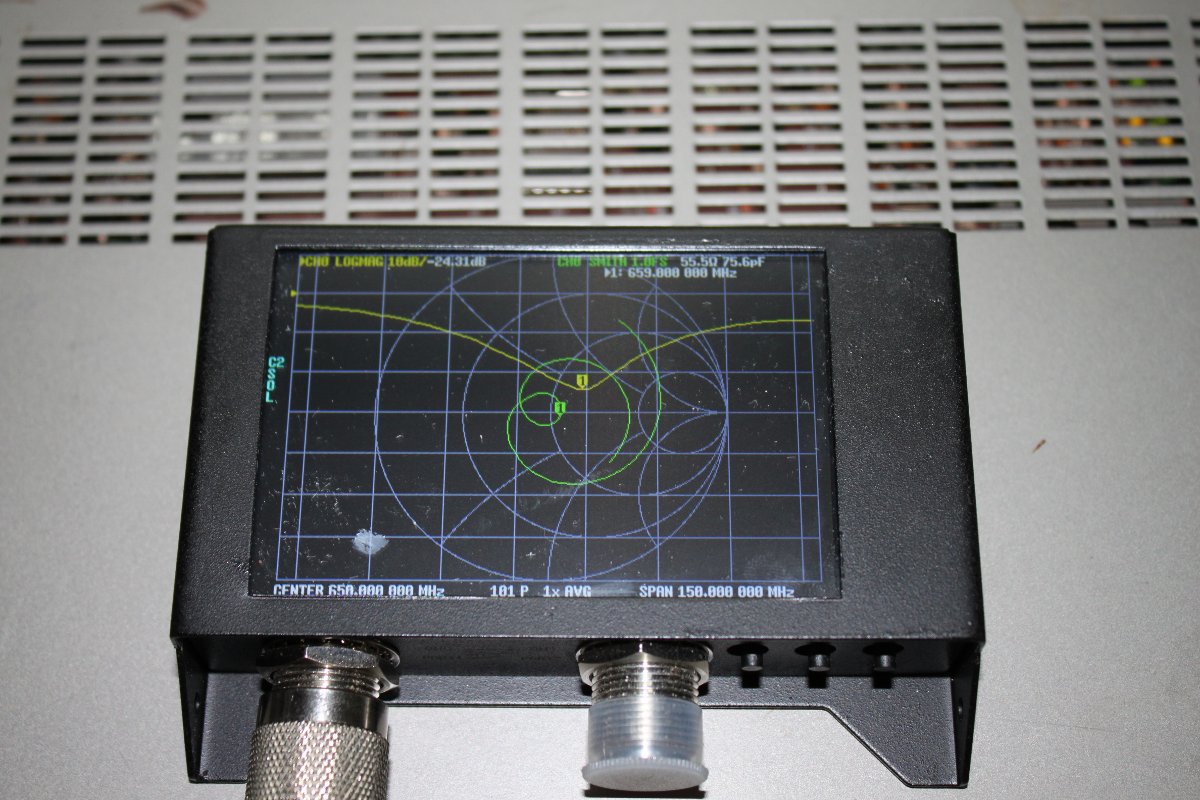

Recently, I pried open my wallet and plunked down the sum of $150.00 for one of these little devices. Now, to be certain, this is not a replacement for a real VNA, especially at a high-power broadcast site. However, it can be used for basic troubleshooting and I have had a good deal of fun fooling around with it.

First, a few quick specifications:

- Type: SSA-2N NanoVNA V2.2

- Frequency range: 50 KHz to 3 GHz

- Power output: -50 to +10 dB

- Measurement points: 201 (or 1024 with software and computer)

- Measurement types: S11, S12 and S21

- Screen Size: 4-inch touch screen

- Traces: up to 4

- Battery: 3000mAh Lithium Ion

- Software OS (VNA-QT): Win 7, Win 10, Linux, MacOS

The unit I purchased came with a small carrying case, calibration loads, and test jumpers. The software is downloadable and easily configured.

What I really like about it is the internal battery and the touch screen.

So what can it be used for?

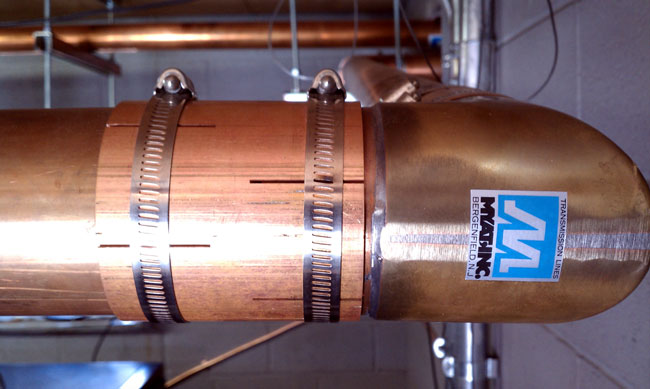

- Test a coaxial cable

- Measure the length of a coaxial cable

- Figure out what frequency an antenna is designed for

- Tune a 1/4 wave stub to make a notch filter

- Measure the characteristics of a crystal/holder

- Measure a capacitor

- Measure an inductor

- Tune a parallel resonant LC circuit to make a notch filter

- Tune a filter can

- Test a high pass, low pass or band pass filter

- Sweep an antenna (Simple AM, FM, RPU, STL, WiFi)

- Check isocouplers for proper circuit functioning

- Etc

Pretty much anything you need to know about RF antennas, filters, and transmission lines can be learned with a VNA. One thing to keep in mind; the measurement points are limited, especially in the stand-alone mode. Thus, the smaller the frequency span, the better the measurement resolution will be.

While this is a very inexpensive device designed mainly for Amateur Radio, it can be useful to diagnose antenna and transmission line problems. Would I depend on it to make precise measurements? No. Especially things required by the FCC like base impedance measurements on an AM tower or channel filter measurements for a TV station. Would it work at a high RF transmitter site with multiple AM/FM/TV transmitters? No and chances are you might burn out the front end. Those types of things are best done with professional equipment that has much better accuracy and resolution.

It is a pretty good little tool for basic troubleshooting. One can look at the individual components of an AM ATU for example, or measure the input impedance to see if there has been a shift (should normally be 50 ohms). It is small enough that it can be included in a basic tool kit. It is self-powered. Not bad at all for the price.