Part II of II

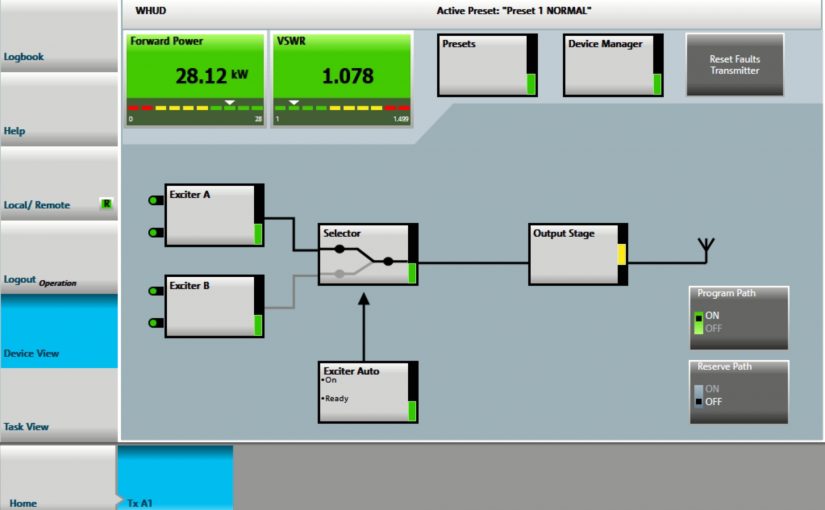

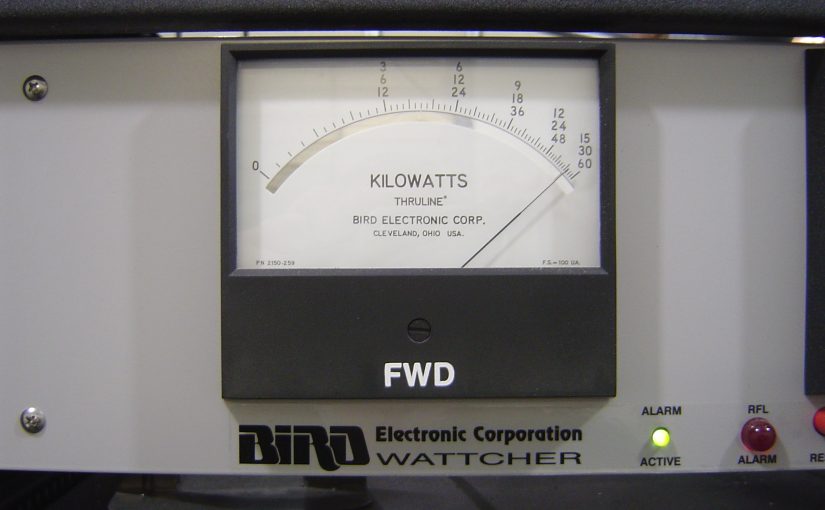

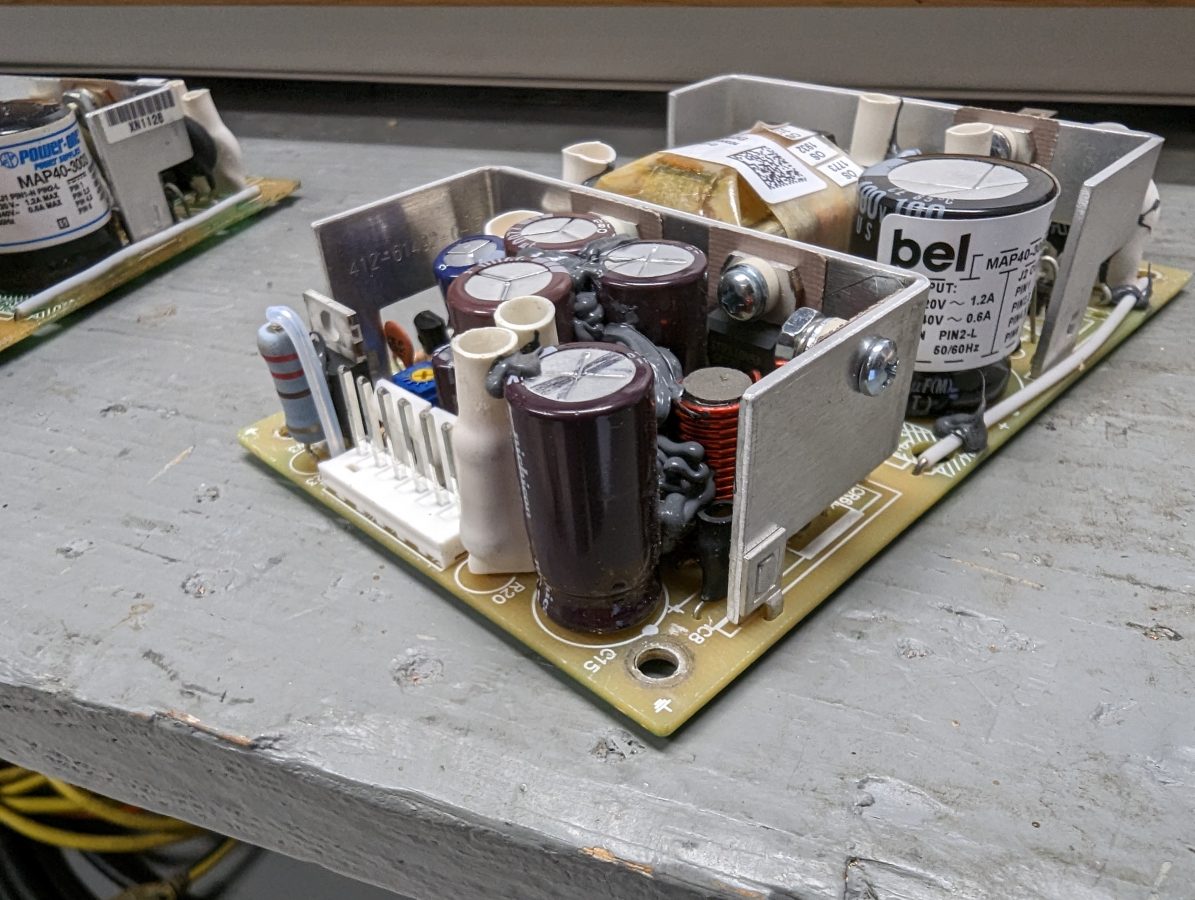

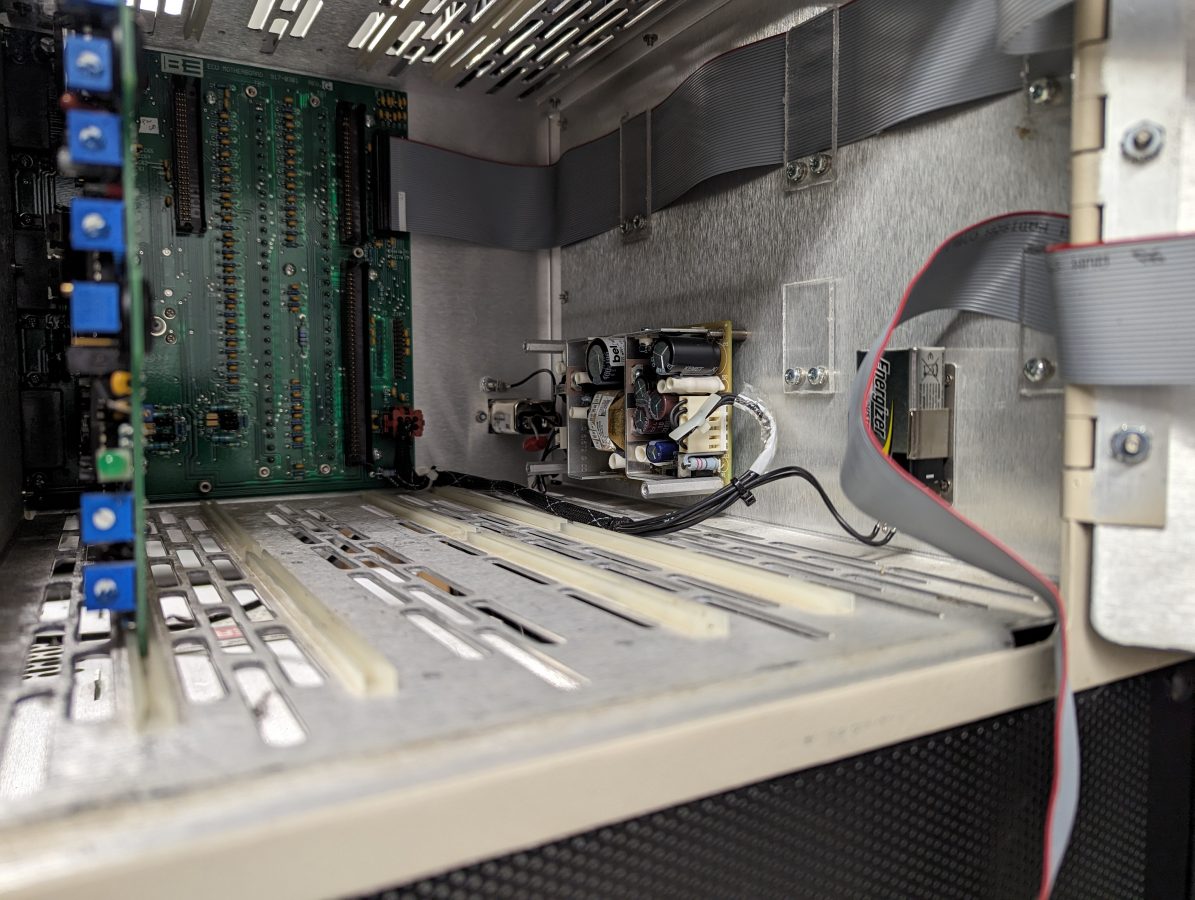

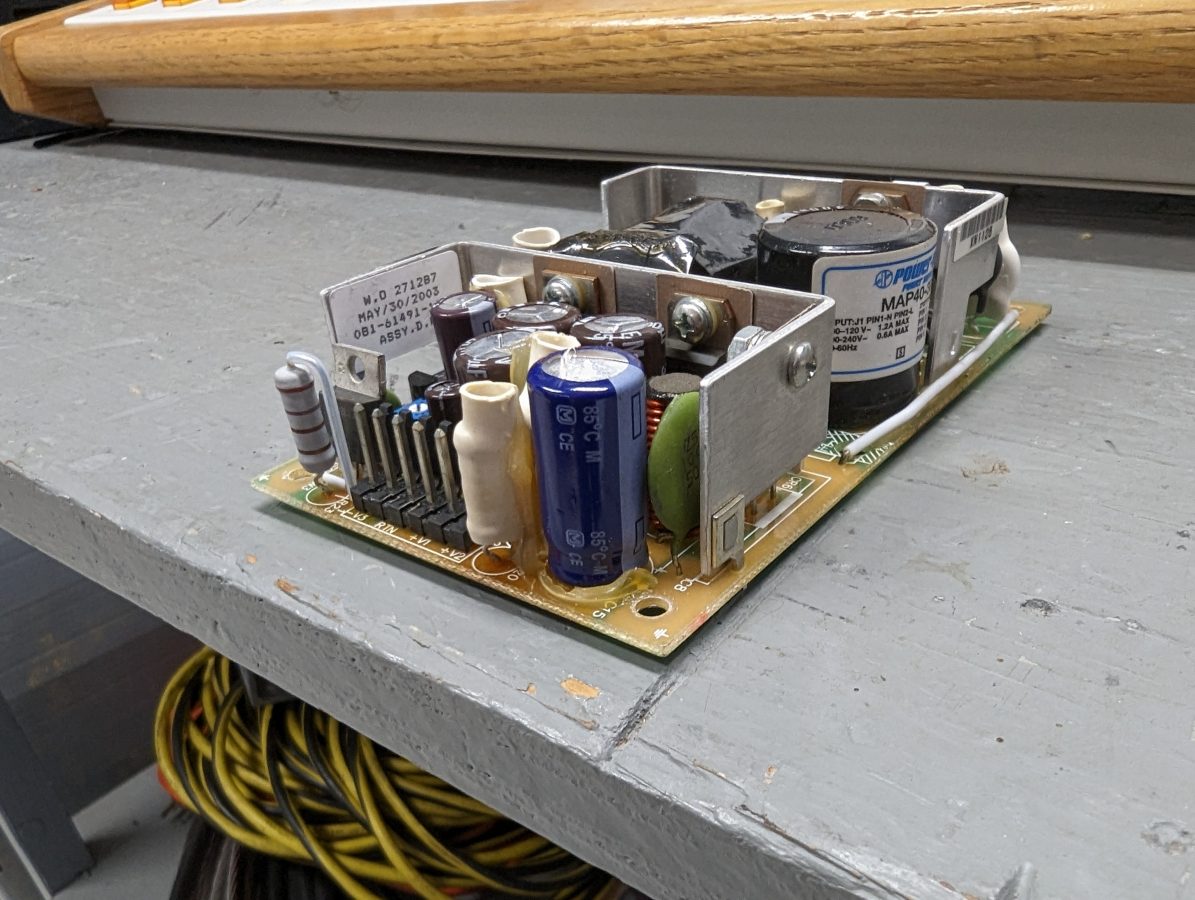

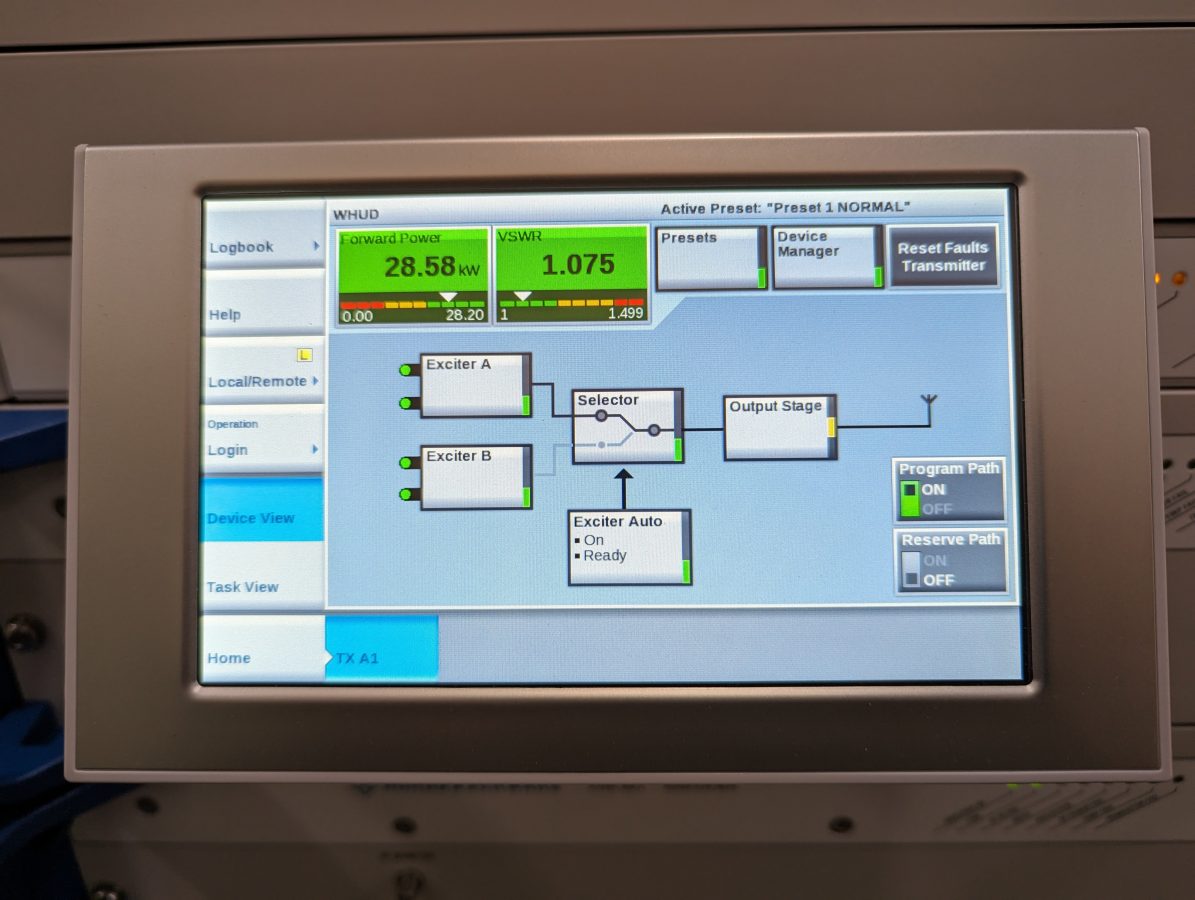

This thing is on the air! There are still some tidying-up things to finish, but it is up and running and sounds great! Here are some pictures of various stages of the installation work:

The filing cabinets hold manuals and spare parts. There is not a lot of room left in this building, so workspace is at a premium. The filing cabinet on the left needs some Windex and elbow grease.

The transformer does not have a neutral reference to the power company. The neutral for the transmitter is derived from the Y output connection. The transformer is also designed to suppress harmonics from non-linear loads like switching power supplies.

The wiring on the pump station and heat exchanger needs a little more work. The client wanted to get this on the air as soon as possible because they are in a book and were running at 50% power. Once things calm down a bit, I will put the backup transmitter on for an afternoon and properly dress the wires.

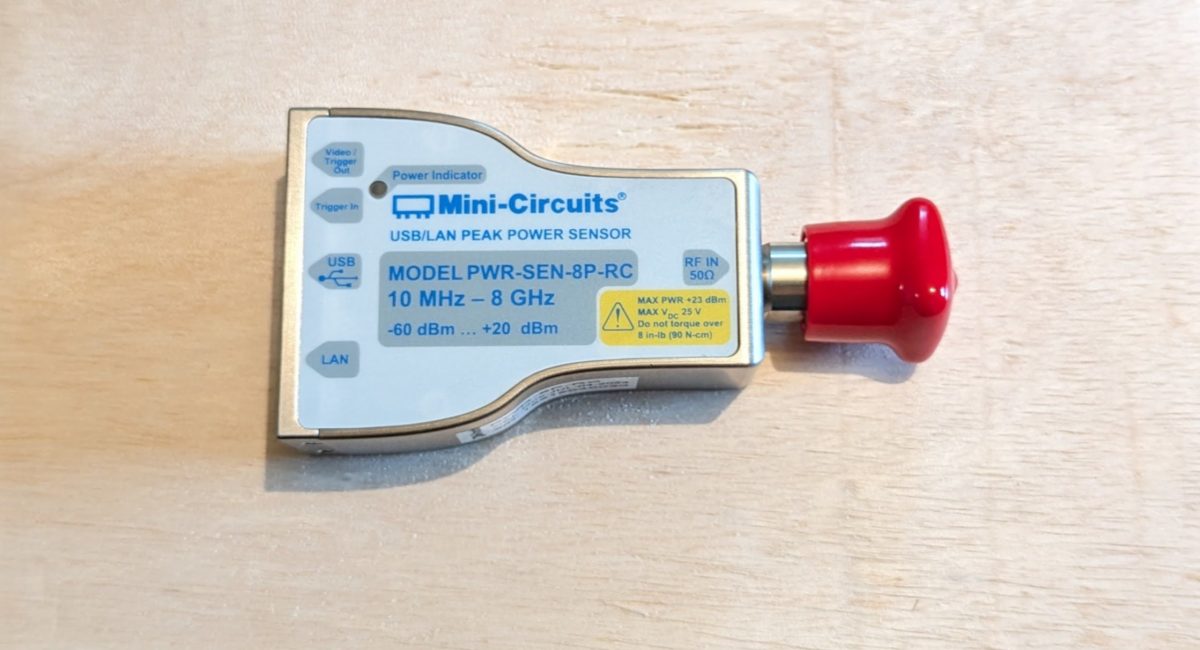

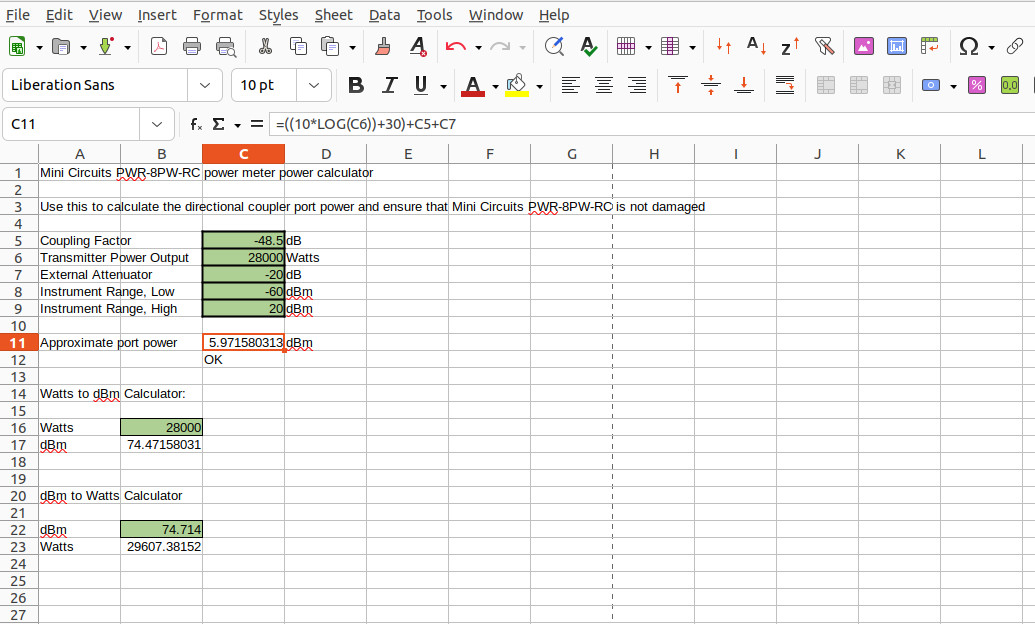

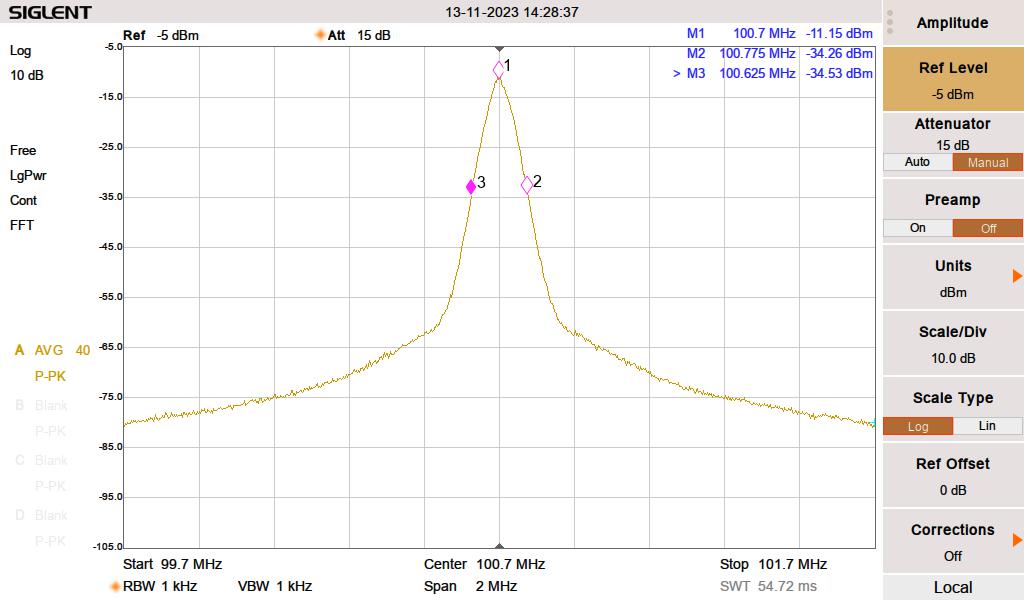

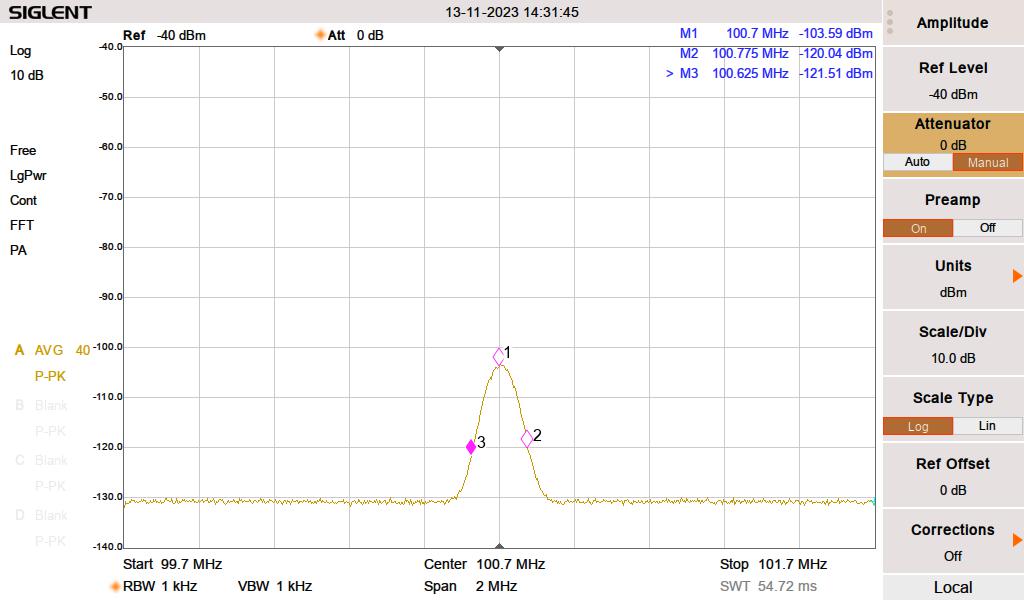

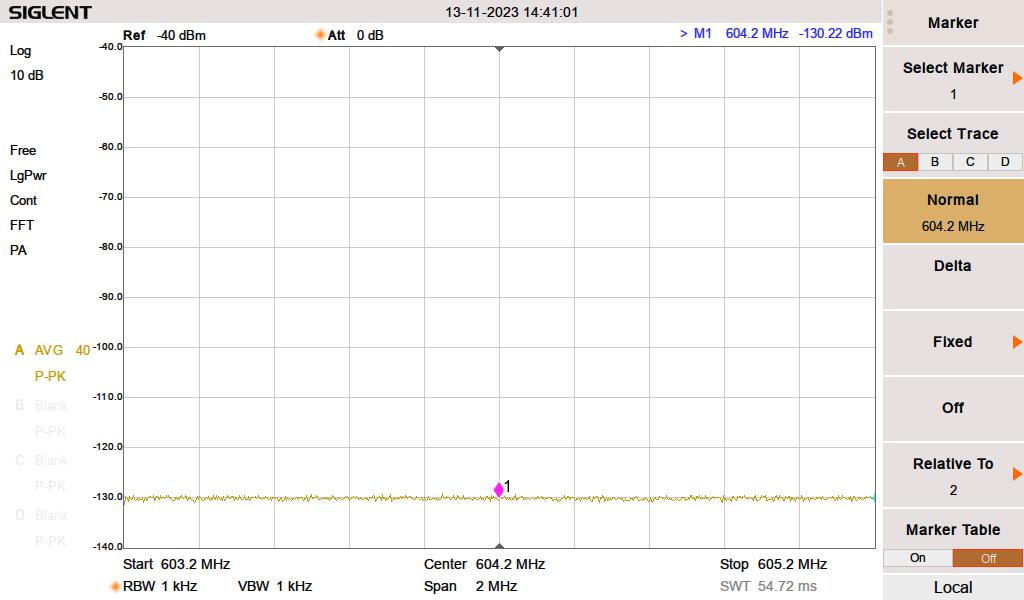

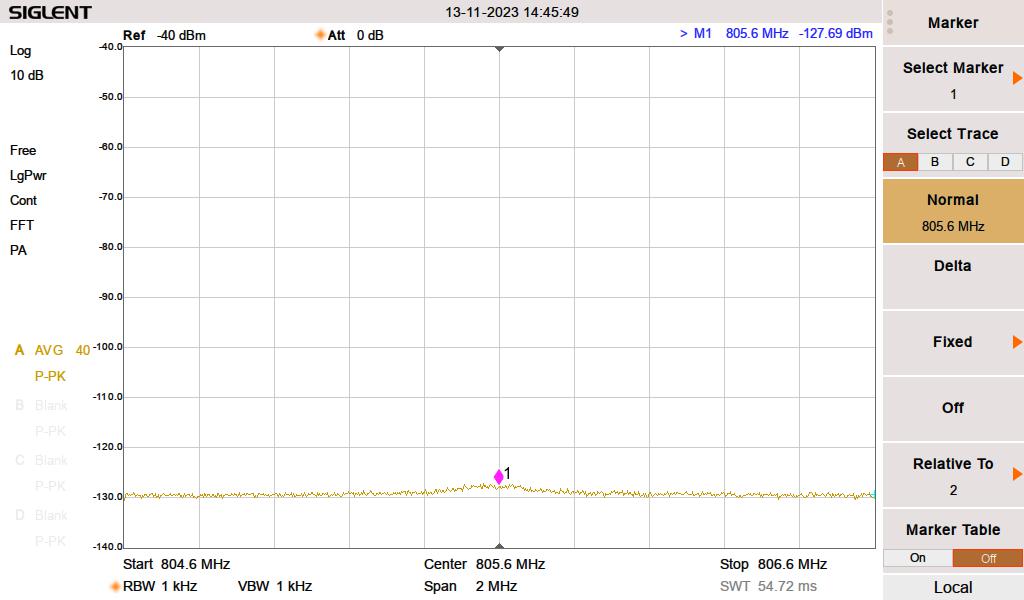

I found this FM modulation analysis function on my spectrum analyzer very useful. The station deviates slightly more than the allocated 75 KHz because of a subcarrier. Overall, it looks good. I measured the harmonics out to the 10th harmonic, most of them were in the noise floor. A few made a slight appearance, but well within FCC tolerances. It is important to document this, as this site has colocated cellular carriers and several E911 services.

FCC part 73.317 states:

(d) Any emission appearing on a frequency removed from the carrier by more than 600 kHz must be attenuated at least 43 + 10 Log10 (Power, in watts) dB below the level of the unmodulated carrier, or 80 dB, whichever is the lesser attenuation.

47CFR 73.317

The rest of the harmonics were measured down to -130 dB with the two NHP-200 high-pass filters in the circuit. The 3rd, 4th, 5th, 6th, and 8th harmonics were unmeasurable. The 8th, 9th, and 10th made slight appearances.

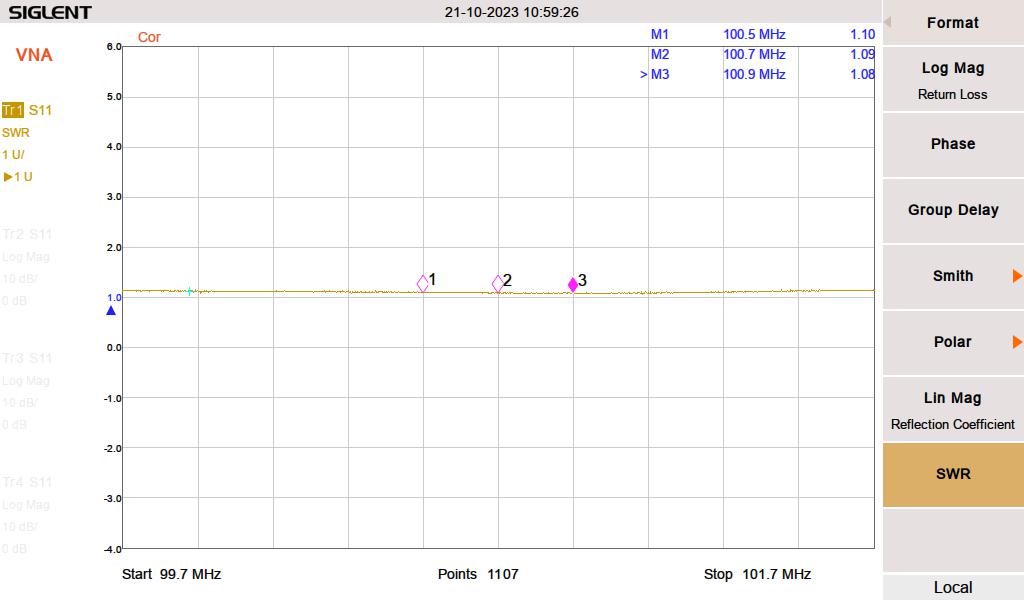

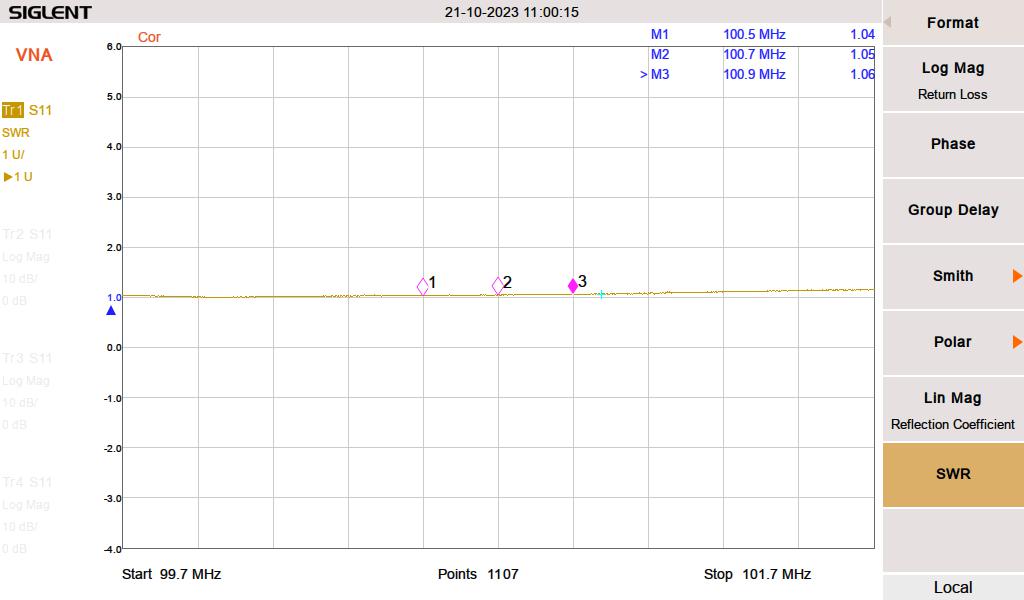

Pretty close, the VNA was inserted at a patch panel, which is the last thing before the transmission line leaves the building. The transmitter goes through an ERI switchless combiner, which probably gives it a slightly better load.

Aside from the finishing details, I need to keep an eye on this for a week or so and top off the Heat Transfer Fluid as needed. It takes a bit of time to get all of the air out of the coolant loop. Another thing; the operating pressure on this is 4 Bar, which is almost 60 PSI. That is higher than other liquid-cooled transmitter systems I have installed before.