As data transfer technology progresses, so do cable types. Category 6 UTP copper cable is commonly used today in ethernet installations where 1000BaseT (or gigabit ethernet) systems are required. Cat 6 cable has a certified bandwidth of 250 MHz (500 MHz for Cat6a). Category 6 cable is a newer version of Category 5 and 5e cable wherein the wire pairs are bonded together and there is a separator to keep each pair of wires the same distance apart and in the same relationship to each other. The four twisted pairs in Cat 6 cable is also twisted within the overall cable jacket.

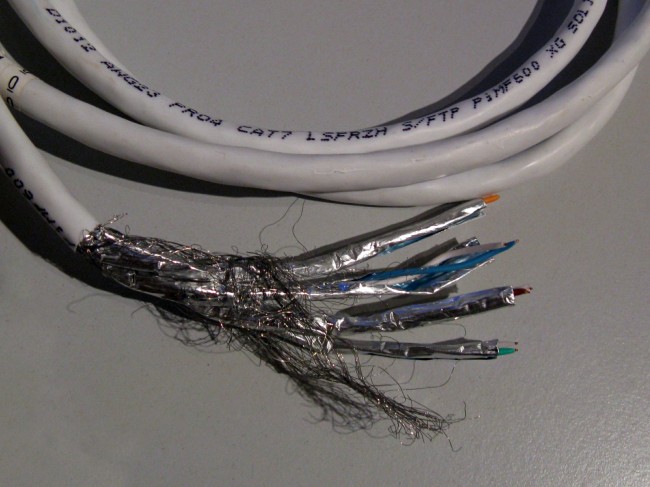

Category 7 cable is much different from its predecessors. It has an overall shield and individual pairs are shielded:

Shields on individual pairs are required to reduce cross-talk (FEXT, NEXT). It also requires special shielded connectors called GG45 plugs and jacks. Pinouts and color codes are the same as gigabit ethernet (Category 5e and 6) however, Category 7 (ISO 11801 Class F) jacks and plugs also have to contact the corners of the connector or jack. This allows better shielding. A small switch in the jack senses when a Category 7 type connector is inserted and switches to the corner contacts, thus keeping jacks and patch panels backward compatible with Category 5/6 cables.

Category 7 cable is rated for 600 MHz bandwidth (1000 MHz for 7a) which translates to 10 GB ethernet. This was previously the domain of fiber cable. Copper cable has some advantages over fiber; lower propagation delays require less complicated equipment, copper is less expensive than fiber and more durable. It is nice to have the flexibility to use copper cable on 10 GB ethernet for runs of 100 meters or less. Longer runs still require fiber.

Category 7 and 7a cable looks remarkably similar to the older Belden multipair “computer cable” pressed into service as audio trunk cable seen so often in older studio installations.