The contracting company I work for takes care of 40-50 radio stations at any given time spanning from NYC and southern Connecticut up to the Canadian border. Stations or groups sign contracts and some go by the wayside on a fairly regular basis. All of this makes for the “Giant Box of Keys,” to be carried around in the work truck or whatever vehicle one is driving while on call.

The problem with the Giant Box of Keys is it never seems to be up to date. New stations or groups join and didn’t get added. Other stations fire employees and feel compelled to change the locks after doing so. Therefore, I have found the Giant Box of Keys to be a hit-or-miss proposition. In my former life as Director of Engineering for Pamal Broadcasting and Dame Media before that, I sought to simplify things as much as possible.

I found that replacing all keyed padlocks with self-set combo locks made life much easier. All of the tower fences, transmitter site fences, and road gates now had the same combination and could be changed to another combination easily if needed. That eliminated digging through drawers looking for tower fence keys and or long walks back to the transmitter building because I forgot the key or the key didn’t work. Taking that a step further, I began to replace the door locks with these:

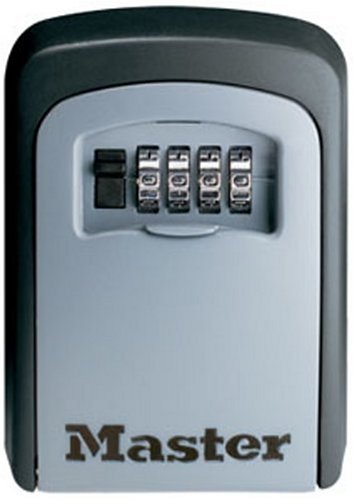

Unfortunately, those door locks are a good deal more expensive than the padlocks, somewhere between $300-400 per copy. I only got a few done before the end came. An alternative to this is a key lock box:

Of course, these are not foolproof either. Occasionally, some previous users will forget to put the key back in the box. I have also had one such box frozen under a lump of ice and once somebody swiped the whole box off of the wall with the aid of a sledgehammer or something.

There are some places where this approach will not work, such as high-security sites or leased sites where the landlord dictates the lock policy.

Still, whenever possible, using combo locks saves time and money in the long run. Rather than using precious engineering hours to make and distribute copies of keys, we can be more focused on doing real engineering work.