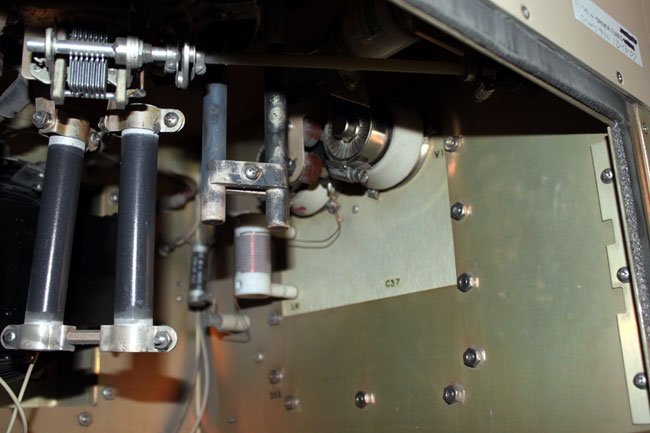

It’s a cute little thing. These were often used for driver tubes in FM broadcast transmitters. With the naming conventions of ceramic tubes, we can tell quite a bit about the unit without even looking at the datasheet.

- The first number indicates the number of grids in the tube, 3 makes it a triode, 4 tetrode, and 5 pentode.

- The C means it is a ceramic tube

- The X indicates it is air cooled, a V is vapor cooled, W is water cooled, M is multiphase

- The 250 is the plate dissipation is watts

- B is the design revision.

Thus a 4CV100,000 is a vapor-cooled tube capable of dissipating 100,000 watts, something one might find in a high-powered MF or HF transmitter.

Other bits of critical information about tubes would be maximum plate voltage, maximum screen voltage, maximum grid voltage, maximum screen dissipation, maximum grid dissipation, and filament voltage. Something to keep in mind when tuning a transmitter.

This particular tube is installed in the driver section of a Continental 816R2 transmitter.

I have noticed that these tubes have a much shorter life than there predecessors. Back ten or twenty years ago, they usually lasted 12-14 months. The latest set lasted only 8 months and both units failed catastrophically. That points to one of two things; either something in the transmitter has changed or something in the way the tubes are manufactured has changed. Once the new tubes were installed, I checked all of the parameters against previous maintenance logs. I also checked things like air flow, dirt and other possible culprits.

I could find no changes in the transmitter. The only thing I can think of is the fact that the tubes are installed horizontally, which causes the elements to warp and eventually break or short.

I am thinking we may try to convert the driver section of this transmitter to a solid state unit. The transmitter itself is 24 years old, but is still works and sounds great. I’d hate to get rid of it because of its driver section.