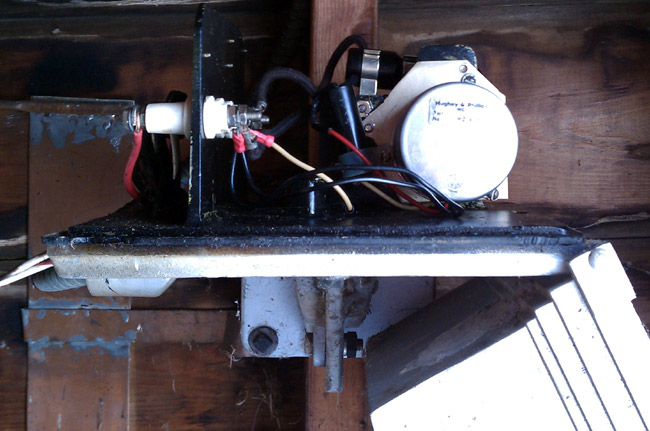

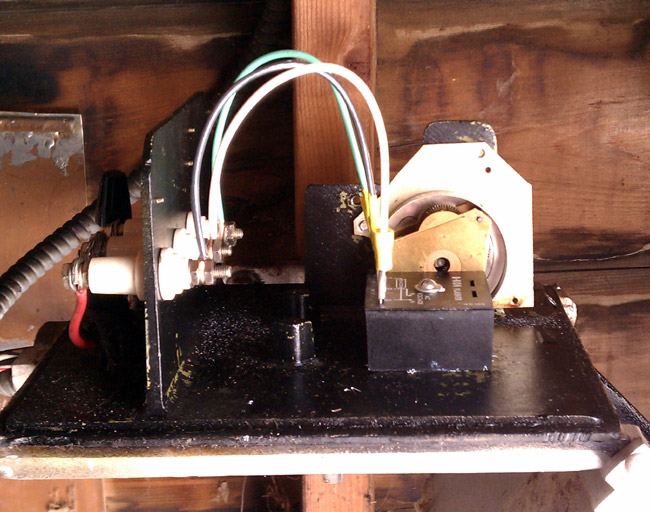

This is a Hughey Phillips mechanical tower light flasher that has been in service since 1960. Basically, it is a motor connected to a cam that rocks a mercury relay back and forth. These were standard technology for tower lights from the 1930s through about 1970 or a little later. They were very reliable, we still have some with a “pancake motor” in use on some of our towers. They were very robust and immune to lightning damage, RF interference, and other problems. The only maintenance that I can think of is lubricating the motor bearings. Eventually, however, they do wear out. Cold weather seems to take its toll, often causing the motor to stop.

This particular unit is mounted inside the tuning house for the far tower (north tower) at the WGHQ antenna array. It has finally reached the end of it’s existence; the motor bearings are shot and it has gotten stuck in both the on and off position this year causing the FAA to be notified of the malfunction.

Today, I am replacing it with a solid-state flasher (SSAC B-KON FS155-30RF). Solid-state flasher units have been known to malfunction in high RF fields, such as AM towers. To cure that, the manufacturer has built-in 0.01 uf bypass capacitors, hence the “RF” suffix. Older units did not have built-in bypass caps, so external 0.1 uf bypass capacitors were normally installed on units mounted to AM towers. While I was working on this, I turned the transmitter down to 500 watts, no need to get any RF burns.

Naturally, this has to happen after there is two feet of snow on the ground. Also, it should be noted that this is the furthest tower away from the transmitter building. Now where did I put those snow shoes? Never mind, it has been very cold and the ground is frozen solid, I’ll take the truck… This is good because I will have all the tools, drills, nuts, and bolts without having to walk back and forth several times in the snow.

I removed the motor and mercury-filled relay. I’ll have to figure out how to dispose of the relay. I then drilled a mounting hole through the base of the old flasher housing and bolted the solid-state relay to it. This is required because the solid-state relay needs a pretty good heat sink.

Turn everything back on and: Ta-da! All works normally, the tower beacon is flashing away up there. Time to leave.

Pull forward about 2 feet to turn around and CRUNCH! The truck goes through the ice of a hidden stream. Any attempt to move only makes it worse:

Put in a phone call to the one guy I know that can get me out. About an hour later he shows up with chains, a shovel, and a come-a-long. We attach the come-a-long to the fence support post and pull the truck out backward 1/2 inch at a time. It took us about an hour and a half to get it all the way out so I could drive it back across the field. I’d have taken some pictures, but my guy; was a little grumpy.

I won’t do that again.

Still, I did the job I came to do, so it was a good day after all.