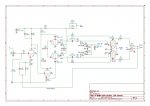

This Broadcast Electronics FM3.5A is 40 years old. There was a small problem that took the station off the air for a couple of hours this morning. The high voltage shorting solenoid fell apart, causing the 40 amp breaker in the service panel to trip.

These types of failures will become more frequent as the transmitter ages. Things like air switches, blower motors, tuning and loading mechanical assemblies, circuit breaker fatigue, plate rectifiers, screen and plate bypass capacitors, exciter and controller fans, etc. The list of potential failure points can get quite long. The fact is, nothing lasts forever.

There is no backup transmitter for this site and there is no easy way to get a temporary unit on line, if needed. This is not the oldest main transmitter that we service with no backup. That honor goes to a CCA DS-3000 built in 1970.

The question is; how long should old tube transmitters be kept in service? Also; how long should we (an independent service company) agree to maintain them? The temporary solution for the above failure was to remove the broken shorting bar and turn the transmitter back on.

That creates a safety issue for anyone who may need to work on the transmitter before the replacement arrives. It also creates a potential liability issue for my company.

I put a big label on the back door indicating that anyone doing service needs to discharge the power supply capacitor with the grounding stick (which they should be doing anyway). But I will feel better when the shorting solenoid is working again.

Get you a wooden dowel from Home Depot and start carving away!

I’m all for saving money and being economical, but at 3.5kW, there’s little excuse to not buy a new transmitter. Particularly in modern times where replacement tubes are approaching the cost of replacing the entire transmitter.

It’ll become a real problem real soon when tubes become unobtanium.

How much is a Nautel VX3.5 these days? I believe they are shipping them now? I think the MSRP is $23150. Let’s assume you can get one for $20k. Let’s further assume this tube tx requires at least one site visit a month just to repair it, and it’s four hours at $150/hr (or $600/mo) and maybe $200/mo in parts on average over a year? Whereas we’ll assume the VX requires 0 hours and $0 in parts for at least a year. And at a guess, I’ll assume the VX is about 60% efficient on the electricity vs maybe 20% for the tube. And that electricity is about $0.08 per kWh. That means 3.5 kW x 5 x 24 hours x 30 days x 0.08 = $1000/mo for electricity for the BE tube tx, whereas it’s 3.5 kW x 1.7 x 24 x 30 x 0.08 = $343/mo.

So that’s $1800/mo vs $343/mo…a savings of approx $1500/mo. Ergo, it will take ~13 years for the VX to pay for itself.

HOWEVER, one can safely assume the repair costs will start rising from $200/mo to considerably more as rebuilt tubes get more expensive and last less and less time. Plus the “lost advertising/make-goods” costs of being off the air for hours, or days, each time the transmitter dies on you. Also it doesn’t take much of an increase in electricity costs for that 15 year period to decrease considerably.

It’s a wild-ass guess, but I would bet your client could very easily see ROI in 10…or even 5…years with a new Nautel VX3.5. That’s a no-brainer in my book but obviously the client gets to make that decision.

Also, admittedly, you may have an issue with a solid-state TX needing better HVAC than might be in there now, since tubes can tolerate high-temp environments much better than a SS can.

If it were up to me I’d start looking hard at charging more for your time to keep these older transmitters running. And I’d definitely jack the rates for the “emergency call” when the thing dies and the owner is crawling up your ass demanding you get it back on the air immediately.

I agree on the tubes; it is time to go solid-state.

Aaron; your math makes sense. Also, there is lost revenue from being off the air. It takes us at least 1 1/2 to 2 hours to get there, then troubleshoot. If we don’t have the part, they could be off for days.

As far as air conditioning; a 1.5-ton mini split system costs about $3K plus installation. Home Depot sells pre-charged DIY systems for $2.5 K and from what I hear, they are pretty reliable.

For old tube units, I have one site where the main TX is a CCA AM-1000D from 1972 and the standby is the original Gates BC-1G that brought the station to air in 1964. Both are very reliable and I love their sound on the air however I agree that from an economical standpoint a solid state unit is the way to go.

The spares for tube transmitters are more likely to both cost more and need priority purchase & freight. We found this out at a station I was involved in. The Harris FM20K needed a new plate transformer – a costly specialty item which weighed plenty as air cargo. The failure of the blower motor also caused some mamnagement stress, although a local firm did a re-wind.

In contrast, our Nautel Ampfet 10 tended to fail less critically and more affordably. Blower failures were spread out over time and over several small fans. PA-related failures followed a similar pattern.

The point re. aircon is well made. Our parsimonious management never seriously addressed this. Consequently, the SS TX suffered, but in a way that allowed the AM transmissions to continue in a commercially viable manner.

Lorne, those old CCA rigs will be on the air for as long as tubes are available.

Paul, bonus points for the use of parsimonious.

The little nylon replacement part is $240.00 from BE.

The sad reality of a lot of smaller broadcasters is that the math doesn’t math when it comes time to make capital expenditures like a new TX or extensive tower work in terms of ROI.

I would suspect more than a few small market broadcasters go dark every year because of catastrophic equipment failures.

Until late last year, none of my clients’ high-power FM transmitters were made in this century. And those old boxes haven’t been replaced, the new boxes are in newly acquired stations.

The BE FM20T I care for managed 10 years out of a tube a number of years ago. The last rebuilt tube didn’t make 3 years at full emission. The rebuilt tube I just installed tuned up squirrelly, and has no emission headroom after performing the traditional filament management routine. I have two other stations with Harris HT-10’s. I just swapped a tube and exciter in one, and swapped exciters in the other. None of these sites are air conditioned.

The two new sites have Nautel NVlt rigs. Both sites are air conditioned. I am expecting a little less drama from those sites.

I have 2 combined 25kw continental 816’s to make 40kw TPO, 1982 vintage, had Tube IPA’s but converted to solid state, it really just runs and runs, tube changes and some light cleaning its been rock solid.

Also have a 1977 Collins 831G in backup that ate a plate transformer when pressed into service. Thankfully my DTO saved a plate transformer 20 years ago that we moved into place rather quickly and got it back on the air, its sparingly used now though.

I have a client with a RCA BTA 1R1 installed in 1968 as the main and only TX, its seen a hard life, been modified to make the light bulb night time power. The past 18 months I’ve taken care of it I’ve done 3 tube changes as finding good 4-400 tubes is a challenge, last change I was able to get it up to about 90% power and make more than 60% positive modulation. The primary crystal heater died and started drifting off frequency swinging +-150hz depending on the temperature. I was able to source a spare, I found tar leaking out of caps, and other components ready to fall apart if I look at it wrong. The station was sold and the new owner purchased a used DAX but is unsure about investing money into this place as theres a bunch of other issues to deal with, so we will see how it goes.

Most of the transmitters I work on are as old or older than me, or I was in diapers when they were new, including the BE you posted about. I’m a Radio/IT guy that was curious about RF, trying to learn as much as I can from my elders.

Since we drifted into AM transmitters, I was already getting only 8-9 months out of 4-400s in a Bauer 707 that was a main until 2003. Pretty fully modulated. It’s living out its days as a backup and still sounds great last I knew (2018). A lot of changes at that site since then so I don’t know if its still there. (then-660, now 660/1490 site in Omaha)