As a part of the re-wiring of a transmitter site, I realized that the site needed a temperature sensor. I believe it is important for any remote transmitter site to have a temperature sensor, too many things can go wrong at a transmitter site.

I recall one incident at WGNA-FM in Albany, NY where a ventilation fan failed on a hot summer day. The Harris HT-10 transmitter stayed on the air while the temperature climbed through 160 degrees inside the building, finally shutting down when the solid-state driver module failed. This site had a temperature sensor and a live operator taking transmitter readings every three hours. They faithfully logged the temperature increase in three-hour increments but didn’t call anyone until the station went off. When I arrived there, it was so hot inside the building that I couldn’t touch a metal surface.

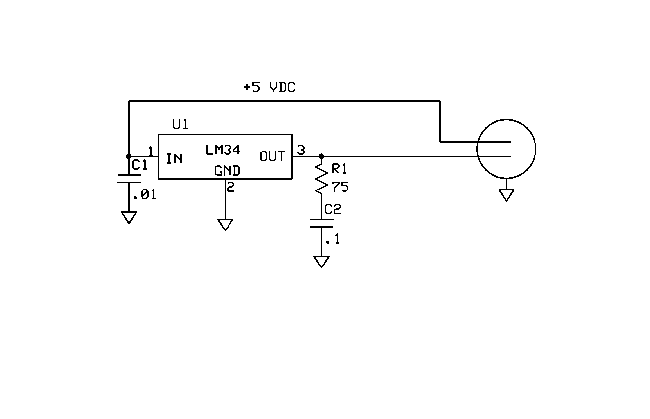

For the present-day project, I looked at the Burk BTU-4, which seemed a little pricey. After doing a bit of quick research, I found the National Semiconductor LM34 a good alternative. This unit puts out 10 mv/degree F, which can be directly calibrated to a metering input of an ACR-16 using the Lin scale. I checked the accuracy by using a piece of melting ice, it was right on. The design and implementation are very simple:

The LM34 is available in TO-46 or TO-92 case. I bypassed the V+ with a 0.01uf capacitor. It should be mounted in a small box with the case of the LM34 mounted on a metal cover or heat sink. The TO-46 version, the case is ground. It can be run on any voltage from +5 to +30 VDC, I used +5 because I had a little wall wart with the right voltage. The wire is any type of balanced audio wire like Belden 8459, etc. The LM34 cost 4 dollars, the rest of the parts were laying around. It took about 15 minutes to create.

The site is air-conditioned, therefore I set the remote control to alarm if the temperature goes above 85 degrees F inside the building.

We use “Sensaphones” which do all kinds of alarm magic. Temperature limits, sound level, 3 sets of closure (or open) contacts, battery backup (“D” Cells), telephone number programming, etc.

Another way would be to use a conventional thermostat, and connect its contacts to the Burke.

Excellent post Paul. That’s a cheap and necessary device.

One other thing to consider is an “industrial strength” building exhaust system, triggered by a thermostat as a backup to the aircon.

The problem with an air conditioned building is that it’s air-tight, so when the unit fails the room becomes a hot-box even on a relatively mild day.

Set the exhaust system thermostat to above the normal maximum temp with the aircon functioning, and it’ll kick in on failure. This’ll reduce the urgency in getting the aircon repaired, and lessen the chance of an off air incident before you get to site.

Okay, I’ll bite, what is a “sensaphone?” They sound quite useful.

a quick google suggests http://www.sensaphone.com/ looks interesting

Doh! Thanks, Daniel.

I have just done this with LM35, that’s cool, thanks Paul !

Paul,

Is there a chance you have the full parts list for this? Thanks!