If a person were to drive south down I-95 through Bridgeport, CT and look off to the left, they would see a 500-foot smokestack for a coal-fired power plant. Side mounted on that smokestack is a 6-bay Shively FM antenna. The antenna is more visible when driving south. That would be the antenna for WEBE 107.9 Mhz. This is right downtown, therefore, I would imagine this station has no problems with reception.

WEBE is a class B FM with a full 50 KW ERP. Most FM’s around here take advantage of a nearby mountain to gain some altitude and thus reduce the TPO a bit. There are several class B stations that run less than 5 KW into a relatively small antenna, but they are way up in the 900 to 1000-foot HAAT range. In this case, the power plant is located right on the Pequonnock River Bay, so the AMSL at the base of the smokestack is only 10 feet. This means lots of watts out and a fairly large antenna.

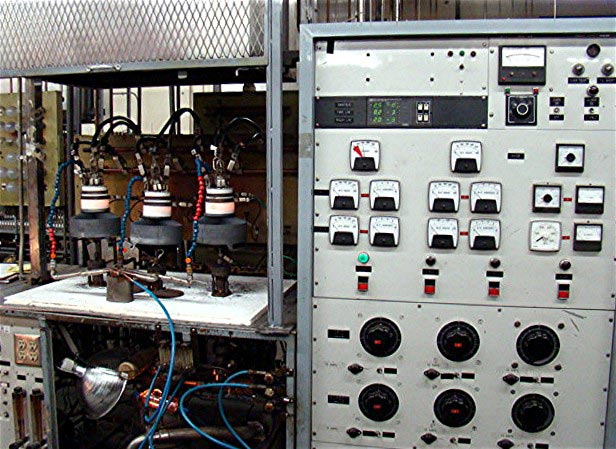

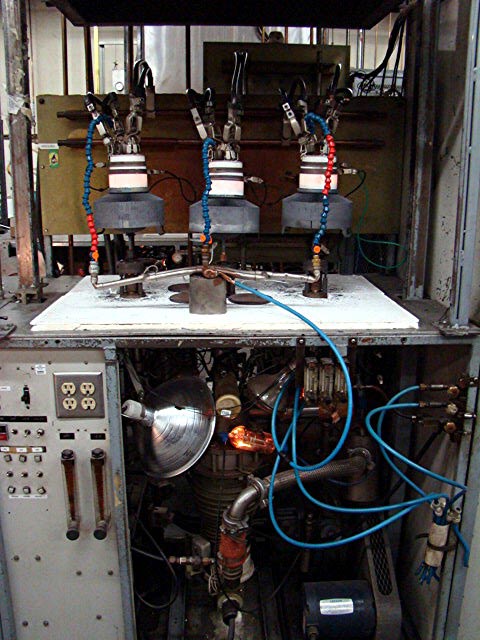

They are using Broadcast Electronics FM35A for the main and backup transmitters. They were installed in late 1986 and are a little long in the tooth.

They run near a 12 KV plate supply, about 3.8 amps making 34 KW TPO. That goes into a six bay Shively 6 bay 6813 antenna centered at 475 feet, which makes the HAAT 117 meters.

One of the problems encountered at the site is the smokestack emissions. It seems that a fair amount of mercury comes out to the top of that thing. In the past, this has caused major problems with the antenna shorting itself out and burning up transmission line. Because of this, the entire antenna system, radomes, and transmission line is supplied with Nitrogen from this liquid nitrogen tank:

The antenna then intentionally bleeds N2 into the radomes continuously, overpressurizing them, to keep the smokestack emissions out. This type of tank is needed because a conventional N2 tank would last about a day, whereas the liquid tank lasts about 20 days.

The BE FM35A decided to blow a 200 Amp fuse on Friday afternoon:

I had a BE FM30A that would randomly trip the 200 amp main breaker every once in a while. I could never find anything wrong with the transmitter, it would just come back on and run normally again after the breaker was reset. I even replaced the breaker thinking breaker fatigue. Still happened. In the end, we replaced that transmitter. In this case, I don’t see that happening anytime soon.

BE FM35A heavy iron:

I would not want to replace this thing, it must easily weight 1,000 pounds.

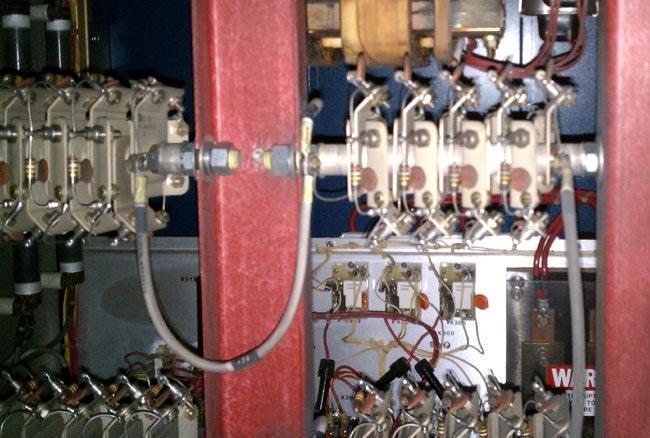

And rectifier stacks:

12,000 volts DC. That will light up any dirt, dust, piece of fuzz, etc. in the transmitter.

It is one of the more unique FM transmitter sites I’ve ever been to. Every time I see it, I am reminded of that song, Smokestack Lightning. My favorite version of that song is the live recording by the Yardbirds