I am reminded of a Pink Floyd compilation album from the very early 70s. The music dates back to the late 60s and Syd Barrett. Poor Syd; shine on you crazy diamond!

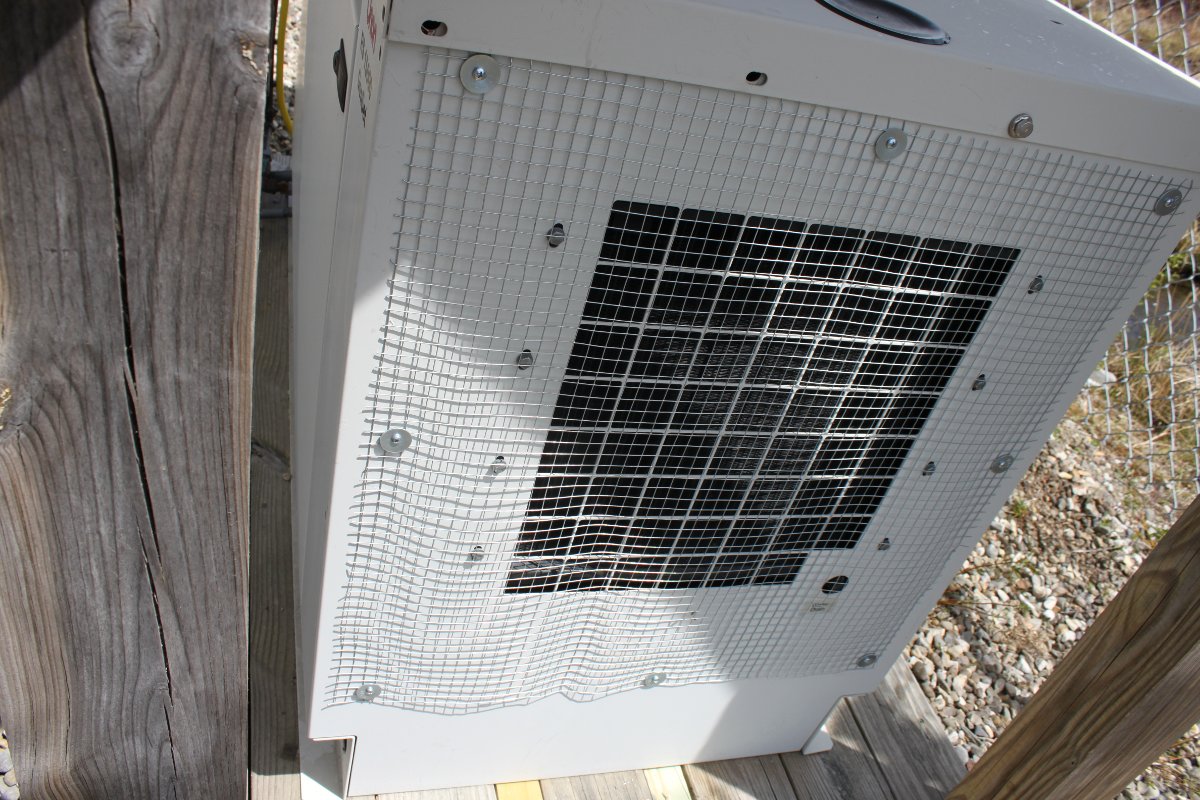

I recently finished installing these rather nice GatesAir FLX-40 transmitters:

Audacy New York decided to move 94.7 from the East Orange, NJ location down to the WOR transmitter site in Rutherford, NJ. Acting as contractors for GatesAir, we installed these two transmitters. I can say, I like the liquid-cooled transmitters for several reasons. First, once installed, they seem to be very stable. I believe that the cooling scheme helps prolong the life of the RF devices by keeping the junctions at a constant temperature. Those semi-conductor junctions are tiny for the amount of current that they need to handle. Second, they cost less in the long run to operate. Anytime a refrigerant cycle can be skipped, that reduces or greatly reduces the electrical use. The Heat Exchangers in this system use VFD’s for fan motor control. That means more constant control over the HTF temperature and reduced electrical use on the fan motors themselves.

The pump stations have backup pumps as well. In the newer transmitter firmware, the pump control needs to be set up to automatically failover to the standby unit. It is a couple of clicks in the GUI to do this.

We didn’t have anything to do with the antenna installation, however, it is a good-looking antenna! ERI 4 bay 3 around mounted on one of the WOR towers.

Overall, this was a good project. Lots of moving parts during the installation, but we were flexible working with the client and other contractors and sub-contractors on site.