Some things I have been working on lately:

Finishing up a transmitter site rehab. The BE FM20T is nearly 20 years old. The BE FM2C transmitters are new. There is also a rack of new fiber equipment and CODECs. This site has good utilization; there are three stations on one tower with a shared STL antenna and generator.

Energy Onix ECO-6 tube-type transmitter. One of Bernie’s better designs; a grounded grid tube with a solid-state driver section. This one needed some fans replaced and a new tube.

I wonder how much the guy tensions have changed…

The reason why you do not use a POTS line phone during a thunderstorm.

I took a tour of the USS Slater, a museum ship in Albany, NY. The museum has painstakingly restored the ship to its WWII configuration. The main transmitter is the RCA TBL-8 seen in the left/center of this picture. This unit put out 200 to 400 watts CW or 150 watts AM phone. During the hostilities, it was turned off as allied ships observed radio silence unless they were sinking (and sometimes even then).

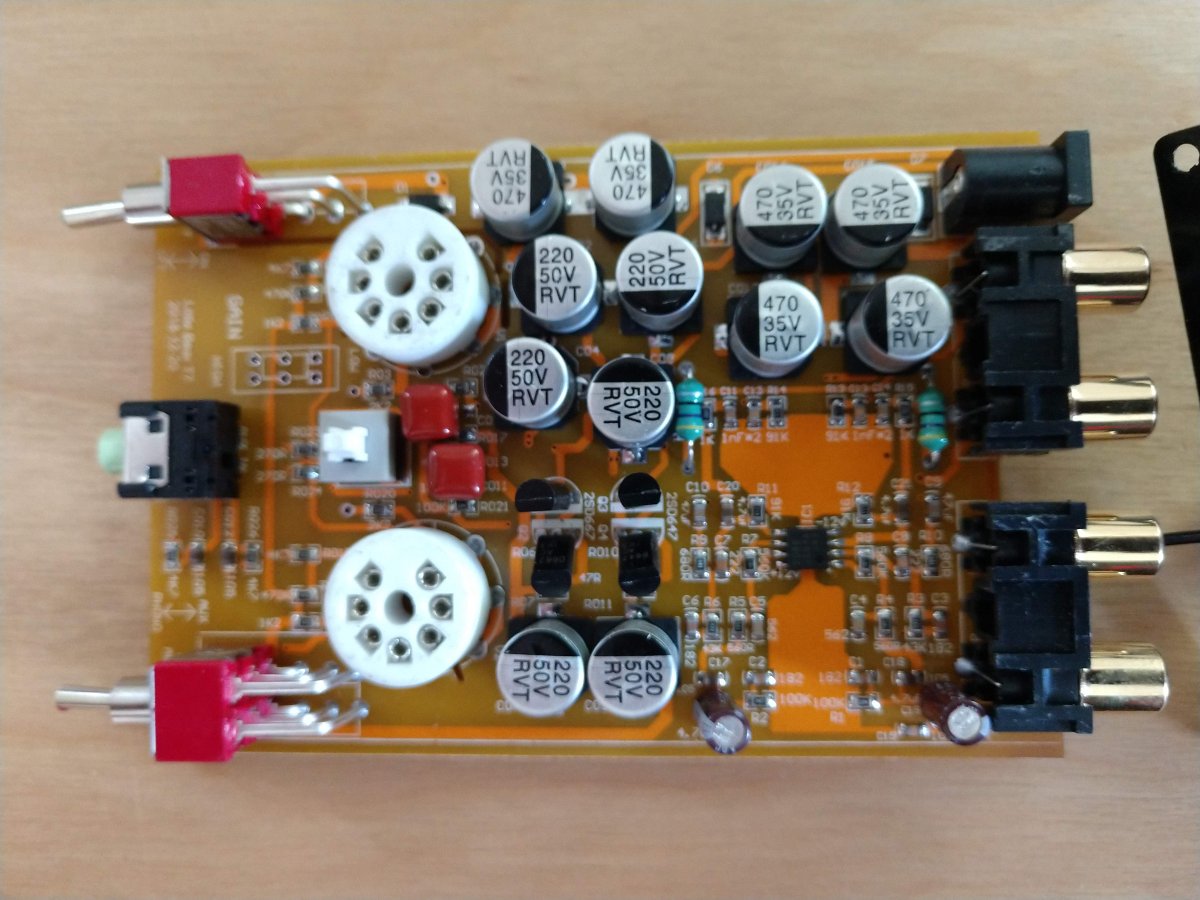

I have been fooling around with this little 6AK5 preamp. I find it works very well and sounds better than the built-in phone preamp on my Kenwood VR-309. The FU-29 tube amp did not come with a phone preamp.

This is a short video clip of an audio processor at one of our transmitter sites. The fancy lights around the control knob are designed for the program director. They are saying “Buy me… Buy me…”