Today, there will be a quiz.

Recently, we had an AM antenna array go out of tolerance by a good margin. This has been repaired, however, I thought I’d post this information and see if anybody could identify the problem and the solution. Unfortunately, I don’t have prizes to give away, however, you can show off your AM engineering prowess.

All of the information is pertinent:

- The station has two directional arrays (DA-2) using the same towers; the nighttime array is out of tolerance, and the daytime array is not affected and is performing normally.

- There were no weather events connected with this event; no electrical storms, no major temperature changes, no rain events, no freezing or thawing, etc.

- The problem happened all at once, one day the array was performing normally, and the next day it was not.

- Station management reports that some listeners were complaining that they could no longer hear the station.

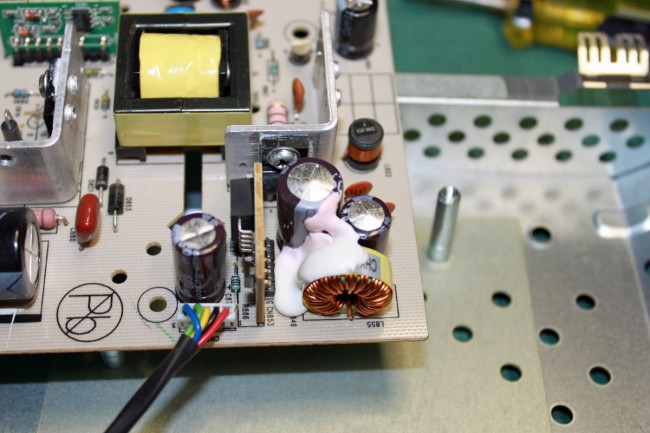

- The ATUs and phasor were inspected; all RF contactors were in the proper position, no damaged or burned finger stock and no evidence of damaged components (inductors or capacitors) was observed. Several mouse nests were cleaned out of the ATUs, however, this did not change the out-of-tolerance antenna readings.

- The towers are 1/4 wave (90 electrical degrees) tall.

Readings:

| Tower | Phase angle as licensed | Current ratio as licensed | Phase angle as read | Current ratio as read |

| 1 | 147.2 | 0.583 | 149.5 | 0.396 |

| 2 (reference) | 0 | 1.00 | 0 | 1.00 |

| 3 | -137 | 0.493 | -125.8 | 0.798 |

| 4 | 107.5 | 0.481 | 92.7 | 0.355 |

| 5 | -38.1 | 0.737 | -60.2 | 0.623 |

| 6 | -178.7 | 0.382 | 142.8 | 0.305 |

Licensed values for common point current is 13 amps, impedance is 50 ohms j0 and there is normally no reflected power on the transmitter. On this day, the common point current readings were 8.9 amps, impedance 38.5 ohms +j5 the transmitter had 340 watts of reflected power.

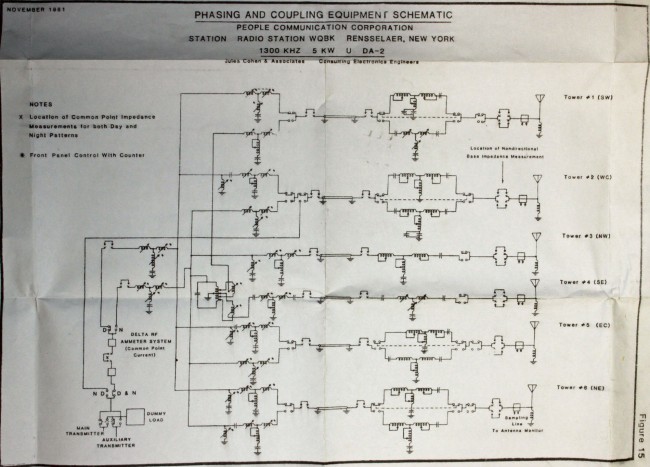

This is the overall schematic of the phasor and ATU:

Aerial view of the transmitter site, oriented north:

So, where would you begin? Ask questions in the comments section.