We have received somewhere between 5-6 inches of rain in the last four days. That, coupled with the deep snowpack and the still-frozen ground has led to some flooding. The WLNA antenna array is located along the Peekskill Hollow Creek in northern Westchester County, NY. Back in 1980, it might have seemed like a good idea to locate an AM station in a tidal swamp along the Hudson River. I am sure the land was not that expensive and from an engineering standpoint, having a continually wet, partially brackish ground system may have seemed like a slam dunk.

Unfortunately, the idea never really panned out in the application. First of all, the neighbors had other ideas, fighting the radio station owners all the way to the NY State Supreme Court. Secondly, technically, it never lived up to expectations. The original non-directional antenna on 1430 was a 1/2 wave tower which by all accounts, worked very well. It did not, however, allow for nighttime service, which is why the new sight and array were sought. By the time the system was built, AM was already in steep decline and I doubt the owners ever recouped their investment.

Fast forward to today. All five base insulators are under water and the transmitter is off the air. These are pictures from last Wednesday after the first flood waters receded from the Monday/Tuesday storm. I imagine it looks worse this morning, although I don’t own a boat and won’t be wading out there to look.

This is tower two of the daytime antenna array. Clearly, it spent some time underwater. We cleaned off all the debris from all the tower bases. A far worse prospect is the ATU’s:

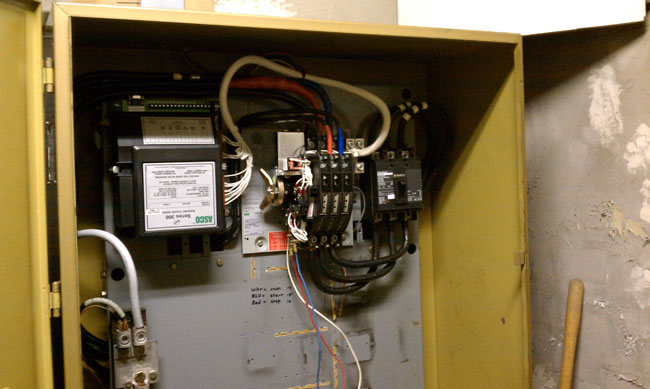

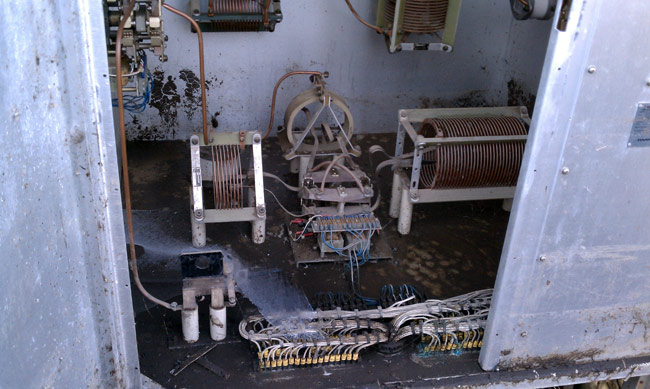

This is the Antenna Tuning Unit for tower 1, which is the reference tower for both the day and night arrays. The E.F. Johnson contactor in the bottom of the cabinet was fully submerged for an undetermined amount of time. The bottom of the unit is covered in fine silt. The high water mark is visible on the right side of the aluminum cabinet.

The contactor is going to need to be replaced, or at least rebuilt. The ATU cabinet will need to be washed out. There are two other ATUs that suffered the same fate.

This is the end of the catwalk next to the Peekskill Hollow Creek looking west towards the Hudson River. The water level reached the bottom of the catwalks and had receded about 4 feet when this picture was taken.

Lookup east, upstream at tower 5.

This is the antenna array looking north, with my back facing the creek. Tower one is the center tower, tower two is on the right and tower four is on the left. The daytime array consists of towers 1, 2, and 3 bearing 300 degrees. The night time array consists of towers 1, 4, and 5 bearing 335 degrees, so the array makes a big X in the swamp. More from the FCC database.

It is going to take a lot of work to clean out all these ATUs and repair the damage. Clean water is at least 1000 feet away. My question is; why bother? Once upon a time, this station was viable, well thought of in the community, etc. Now, I doubt anyone knows it is off the air. The current ownership over the last thirteen years did, what I’d like to call, a controlled flight into the ground. Axing staff, cutting maintenance, and generally neglecting the station. Why not take it dark for a while and figure out what to do with it? Likely somebody would buy it, even if for the land it sits on. Anyway, the grind continues…