We or rather, I have been working on installing this CCA transmitter as a backup unit at one of our sites. It was installed as a backup at another site but was mothballed about ten years ago. Now, we need to get it running again and re-tune it. Seems like a fairly uncomplicated job.

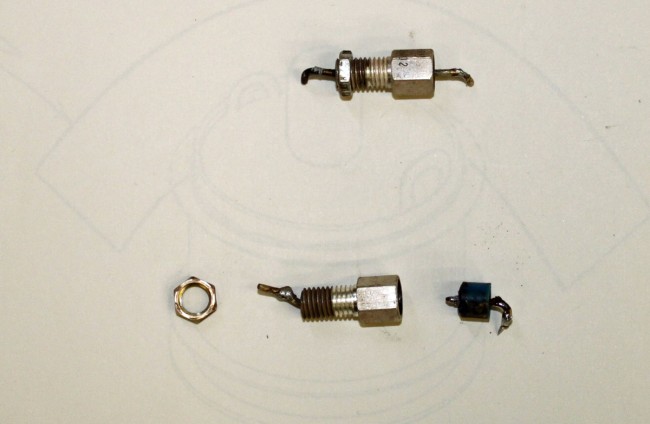

Except, every time I start it, another one of these 1000 pf bypass/feed-through capacitors fails. They are located at various points around the PA enclosure and route AC voltages into and out of that enclosure. The bypass function is needed to keep stray RF off of the control circuits. Normally, they have been failing with a medium resistance fault (40-70 ohms) to the case. That causes the control circuit breaker to trip.

This time, however, it was on the primary for the filament transformer on the IPA tube. Just a wee little pop, followed by some ozone smell and sans power output. I have, thus far replaced four of these and there are seven originals still in the transmitter.

It is time to replace them all, otherwise, this rig will fail when we need it the most. The replacement part is a Mouser 800-24437X5S0102MLF, 1000 pf 500 v made by Tusonix Electronics.

Know what’s causing the failures? Just plain old age, or is there something a bit more sinister happening behind that door?

They seem to be failing of old age. When I look at the failed units, the dielectric around the feed thru wire is all cracked and sometimes falling out.

If the insulation is cracked but the feed thru wire hasn’t moved or shorted to the case, nothing disastrous will happen but they won’t bypass any RF. However, if the wire ends up moving and touching the case, that’ll certainly cause other things to fail. I agree: replace them all. Chances are, there are other old parts that will also fail, especially electrolytic caps. You can’t replace everything, otherwise you get caught in the “might as well” infinite loop.

I just worked on an old 16-channel audio distribution amp last week. Several of the 1% resistors measured open, and this condition changed when I unsoldered them. Rather than have an intermittent unit, I decided to replace all 96 resistors. They don’t cost much but it takes a while to do a proper job. The unit should now live another 30 years; I won’t be around by then to worry about fixing it again.

Since these go into and out of the pressurized PA enclosure, the cracks fill up with dust and debris, this is what caused the medium resistance shorts. I do not know what happened to the one that blew itself in two. Since this transmitter is for backup service, it really needs to work when called on, so they all need to be replaced. As for the electrolytics, there are only a few and there are a few high voltage PS filter caps, but those all look to be in good condition. This transmitter is so simple, that once it gets fixed, it should be reliable for years to come.

I remember those failing every so often when I maintained a CCA 20kW. A good lightning storm would take a few of them out, found more than one with tell-tale arc marks that explained why they were in pieces.

The 1 ohm metering resistors were another failure point, esp. in the Ik metering circuit. Outside a few small parts those transmitters are indestructible.

I have been to Killington its been 20 years I went up there from Atlanta Ga to install a DB electronic transmitter and four 4 panel antenna from Sieal but my work was cut short by driving afternoon snow storm and I missed the lift and hiked down the main slope by my self the station got in trouble up there as the antenna came apart in winds and was order to leave the top fire tower I never knew if the ever got back on the air