Not that I am a glutton for punishment or anything, but I enjoy troubleshooting. There is a certain satisfaction in the analytical aspect of tracking down a problem and fixing it, hopefully in a permanent fashion. Figuring out where a problem is requires a good bit of detective work;

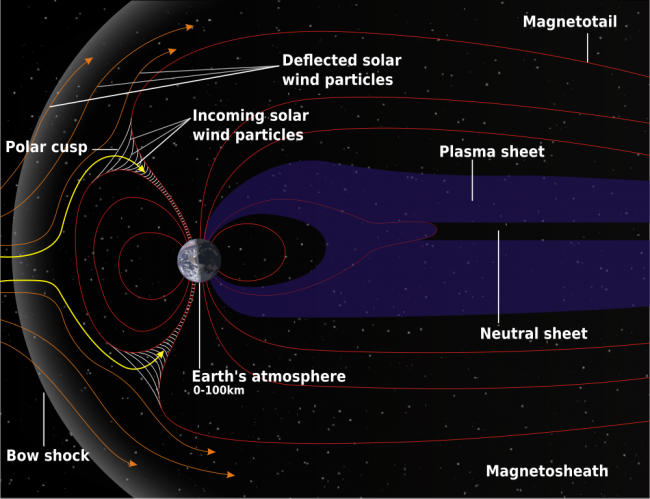

- Examining the clues; what happened before the failure, what are the fault indications, are there any external factors

- Round up the usual suspects; a good maintenance log is helpful here to track re-occurring failures. If the failure cannot be attributed to an external source (such as a power surge or lightning storm), what was the last thing that was changed or worked on?

- Following the trail back to the origin; Often the first failed part found is a symptom, not the actual problem. It takes some skill in reading schematics and making sense of a failure to trace it back to the real problem.

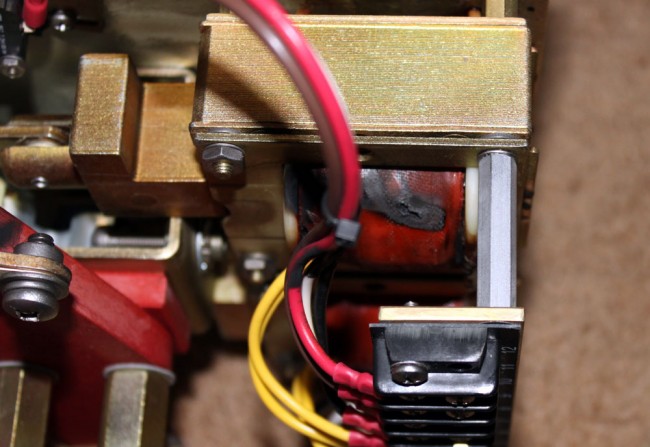

It can sometimes be exciting, like turning on the 25 KV high voltage supply and having big blue flashes issue forth from the top of the transmitter. Sometimes it can be quite frustrating, like when the station owners refuse to spend money to fix a problem. Sometimes it can be dull, like fixing the same problem over and over again because of the previously stated money problem. It’s also disheartening when the problem was caused by the stupid DJ spilling soda in the console. Not that all DJs are stupid, just the ones that spill things into consoles.

The challenge of finding the root cause can often be enlightening. I have often discovered unrelated problems waiting in the wings while investigating the why of an outage. It is great to fix those things before they burn the house down, but this approach often goes unnoticed by the ownership or management. Lately, for some reason, an ounce of prevention goes unnoticed or unappreciated.

There is quite a bit of science to troubleshooting, but there is some combination of personal traits that make a good troubleshooter. These are:

- Inquiring or curious disposition. It is fairly easy to get to the first failed module or part. Discovering the reasons behind the failure and or getting down to the component level takes a good deal more effort.

- Patience. This goes with the second part above, it takes some stick-to-it-tive-ness to trace out the not readily apparent problem.

- Good analytical skills. Often failures generate a cause-and-effect scenario. The effects can be startlingly distractive and mask the causes and the underlying problem.

- Ability to view the large picture. This is critical to discover outside influences and other issues that are indirectly connected to the system or issue at hand.

- Ability to analyze the system design. This requires background training and experience to look at a circuit diagram and discover non-error-tolerant systems. Sometimes these systems can be modified for better fault tolerance.

Poorly designed equipment is the bane of the broadcast engineer. Equipment manufacturers can sometimes fail to follow two key principles: KISS and maintainability. KISS stands for Keep It Simple, Stupid. There is no better design criteria than the KISS principle. Adding layers of complexity increases the failure expectations. Maintenance can be something as simple as cleaning or changing air filters. Making maintenance tasks difficult almost ensures that they will not be done.

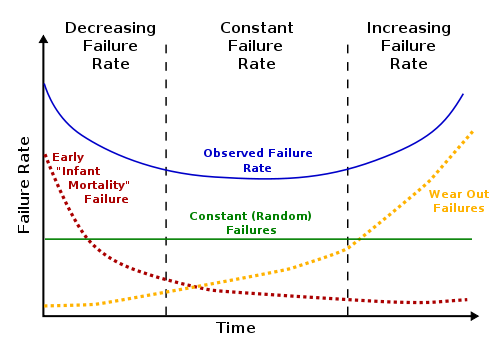

Eventually, all things wear out. It also takes some large-picture skills to know when it is time to replace equipment and that can vary greatly from situation to situation.

I sometimes wonder what the mindset of recent EE graduates is. I always have strived for simplicity and serviceability in design as paramount. It would appear that the new designs are lacking in both of these points. Harris for example is building equipment that is a packaged hodge-podge making it miserable to service. Removing a heavy transformer in order to get at key components is just plain dumb. I wonder how these “engineers” would bag groceries? When Gates was around, particular attention was paid to serviceability. The same for Collins, GE, and Westinghouse. The new breed of design engineer is a typist first, and a thinking serviceman last.