Warm, unmanned buildings in the wilderness are very attractive to all sorts of uninvited guests; mice, rats, snakes, insects, etc. Unfortunately, these can do damage to equipment, as evidenced here:

Thus, some steps need to be taken to secure transmitter sites, generators, outbuildings, and even vehicles from mice in particular. Mice can squeeze into a hole that is .7 inch (17 mm) in diameter when they are fully grown. In many transmitter buildings, this leaves lots of opportunities; coax feed through ports, ingress holes drilled for wires, electrical service entrances, cooling fans, gaps under doors, soffits, etc.

Many people simply call the pest control people who will come and put poison out. That does not solve the problem and can in fact make it worse. If the poisoned mice go outside to die, they are eaten by the snakes and birds that naturally control mice in the wild. Those animals then die from the poisoned mouse. Meanwhile, new mice are being reproduced every 20 days or so. Fairly quickly, the bait is consumed, the mice no longer have any predators to naturally keep the population in check and there is a mouse explosion.

The best way to keep them in check is to seal up the building as much as possible. For some reason, coax entry ports are often left open. This is very easy to fix and whenever tower crews are running new lines, ensure that they apply the correct boot for the port and line.

Another thing that happens; door jambs deteriorate or the bottom of steel doors begin to rust away. This opening is very attractive to insects, snakes, mice, and even plants.

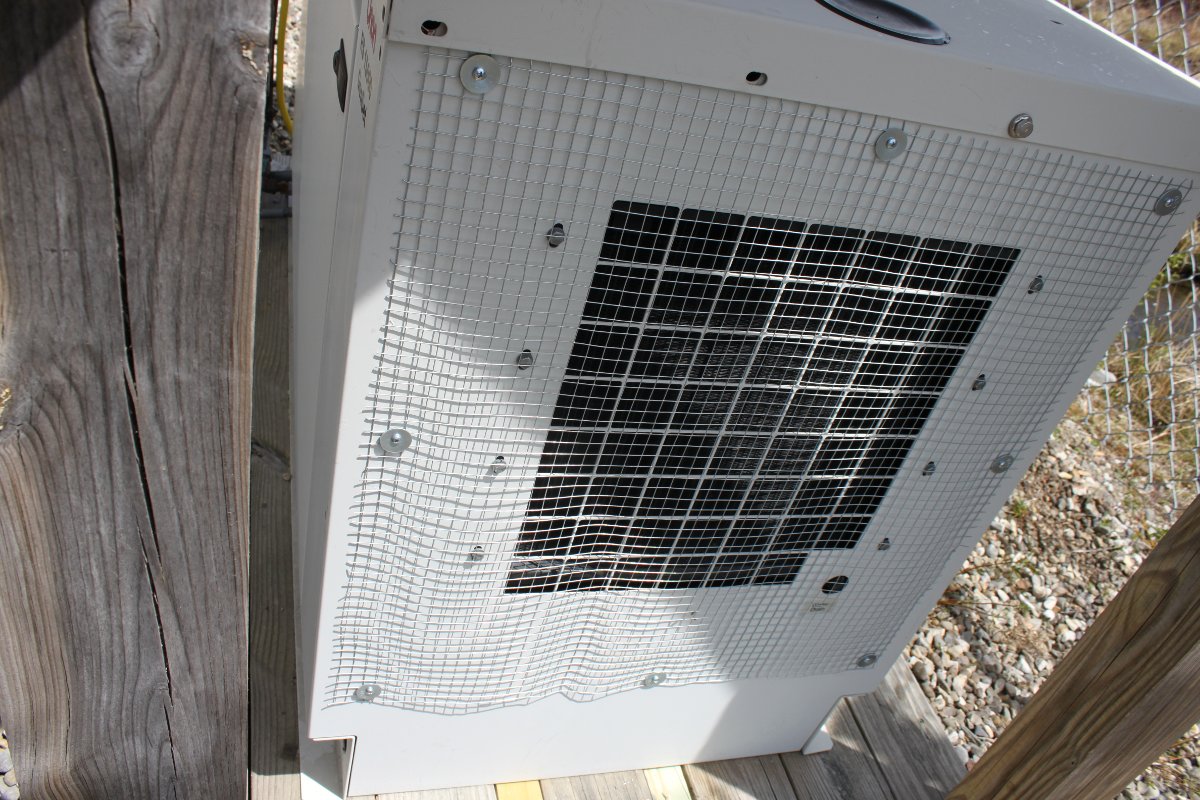

Generators need special attention. Radiator and ventilation openings should be covered with chicken wire. This can be attached to the metal housing with self-taping screws and fender washers. Be careful and look inside the housing to make sure that the area inside the housing where the screws are being applied is clear of wires and hoses.

Ingress for fuel, control, and electrical conductors need attention as well. I found stainless steel pot scrubbers to be effective for filling gaps around these conduits and pipes. They are available on Amazon or many other places.

Other openings can be filled with a combination of pot scrubbers and spray foam. Using spray foam alone often does not work, as the mice will chew through it.

I also keep a can or two of bee spray at most sites. Bees, hornets, and paper wasps love to make nests in propane tank fill covers, ATUs, under air conditioning units, or anyplace else that are sheltered from the rain.