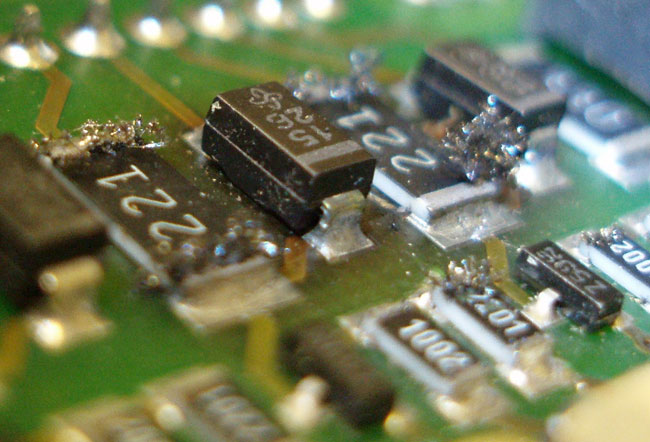

Good troubleshooters are becoming rare these days. To some, the idea of working through a problem, finding and then fixing an issue seems like a time-consuming, wasteful evolution. More often than not, it is easier to replace the entire assembly with a new one, throwing the old one away. This is especially true with computer components. The other option is to send a module or assembly back to the factory for repair. Truth be told, often that is a good course of action when a fully equipped repair bench is not available. Surface mount technology can be difficult to repair in the field, as can many RF components.

Being able to troubleshoot components and assemblies is still a valuable skill. Finding and identifying trouble is a good skill no matter what it is used for. I find analytical troubleshooting skills to be good life skills to have. I think my in-laws are occasionally amazed when I walk into a situation and point to something and say: There it is, fix that.

Many times, however, there is no smoking gun. Those situations require a bit of investigative work. The first step in troubleshooting is developing a history:

- Has this failed before

- Is there a history of failures

- Has it been worked on recently

- Is it new

- Has it been installed properly

- It is old

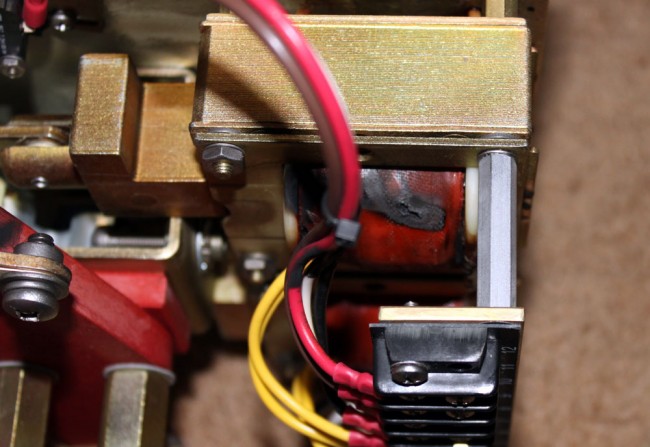

- Has it been affected by some outside force like lightning or a power surge

This is where good maintenance records or maintenance logs come in handy. Recently, I have found many places that lack any type of maintenance documents, which means the repair history is unknown. This makes it difficult to find a good starting point and can greatly increase the amount of time required to troubleshoot a problem.

Once the pertinent history is gathered, it can be organized and analyzed for clues. For example, if something has been worked on recently, that is a good place to start. If something has a past history of failures, that is a good place to start. Newly installed equipment is subject to early failures under warranty due to component failures. Old equipment may just be plumb-worn out. Improperly installed equipment can exhibit all kinds of bizarre failure modes. That information coupled with known symptoms would indicate a good starting point for troubleshooting the problem.

If no good starting point can be discerned, then the next step is to recreate the failure. This usually means turning the thing back on to see what it does. Chances are good that whatever the problem is, it will still be there. Once a good set of symptoms have been identified, then it is time to start working at one end of the problem unit once the failed component is isolated.

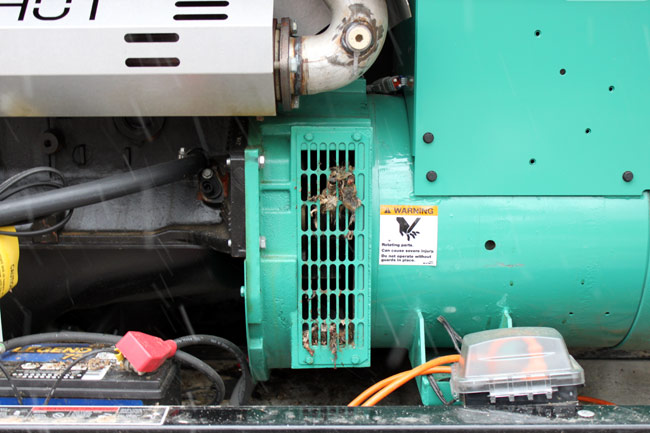

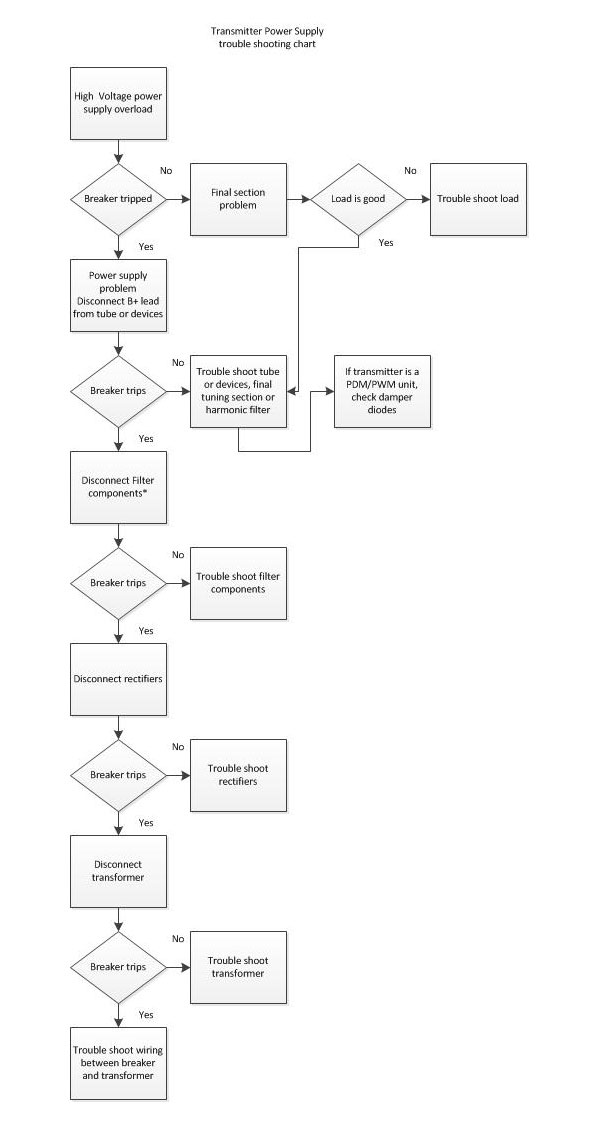

Oftentimes, equipment manuals will have troubleshooting guides. These can greatly speed up the process for large, complicated things like transmitters, generators, and so on. There is also the tried and true troubleshooting chart:

This is an example of a troubleshooting chart for a transmitter power supply. Many equipment manuals will have this type of information in the maintenance sections.

It is also important to note that when working on high-voltage systems, it is necessary to have two persons on-site at all times.

Good troubleshooting skills have many applications.