You know those fancy new facilities pictures with the accompanying article you can normally find in the trades? The article usually expounds on how this guy made the decisions on purchase then these guys worked hard and pulled it all together. Here is the work hard and pulling it all together story.

WEBE and WICC have been in the same studio building for several decades. The Pacific Recorders and Engineering equipment, while great, is tired and worn out. On top of that, an F1 tornado ripped the AC units off the roof last June, ripping the membrane and doing extensive water damage to the facility.

The cleanup/water damage mitigation took some time. All of the carpet and ceiling tiles needed to be replaced. The walls needed to be resurfaced with new drywall. In some cases, modifications such as removing a storage closet from the engineering room, moving a door, and building a new talk studio and WICC control room needed to take place. In short, lots of dust, dirt, and disruption to the station equipment and staff. It has not been trouble-free, as several times computers and consoles failed due to age and dirt.

Sometime about the beginning of December, new equipment and furniture began to show up and the project was underway.

All of the new equipment was stored in the program director’s office. Heh, the program director’s office.

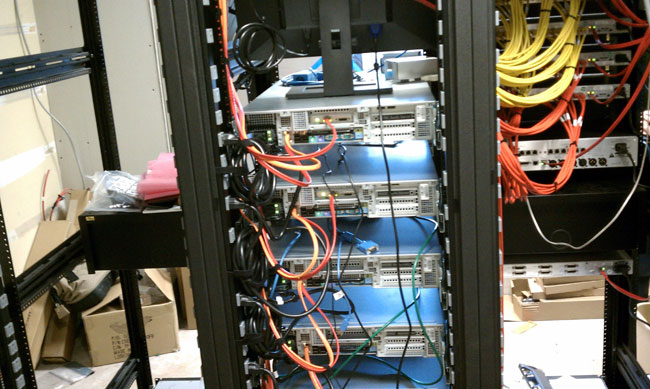

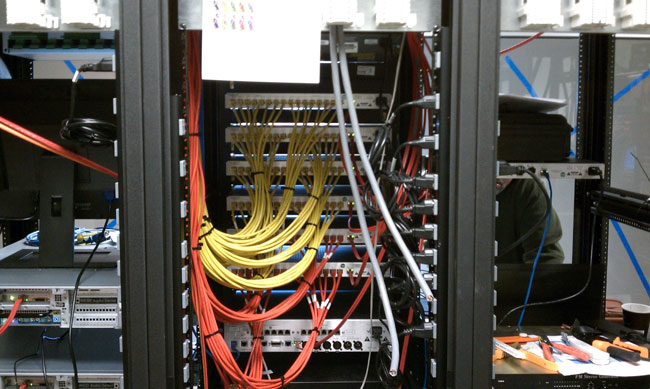

A new rack room was designed around the old one. The old racks are out of the picture to the left. The original rack room had a door into the hall, that has been replaced by viewing windows, the door has been moved to the engineering office, next door. I kind of like the windows, it lets visitors see the fancy computers but keeps them out of the room itself.

The existing automation system is being replaced by Op-X. This is the business end of the Op-X audio servers. All of the network connections are Gigabit using Belden Mediatwist (1872A) Category 6 cable.

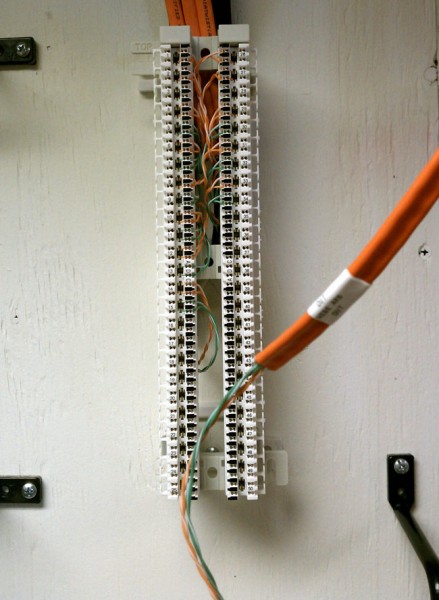

All the wiring from the studios and racks are brought to this wall. The terminations are Krone LSA-PLUS blocks. AES/EBU digital and analog audio is run on Category 5e cable.

Krone LSA-PLUS termination block with Belden Mediatwist cable. All rack and studio wire runs are terminated on this style block. Notice the wire labels, every run is labeled with both termination ends and use. Mediatwist cable is fairly easy to work with, the pairs are bonded, so a special tool is recommended to quickly separate the wires.

Wire tray between the racks and wire wall.

The new WICC control room and talk studio. The Axia consoles are pretty slick. They are not a true mixing console in the traditional sense, they are more like a control surface. Most all of the audio inputs are in the rack room, however, the microphones are digitized in the studio and sent over an IP network to the rack room. All input and output channels are computer configurable and remote controllable. Console inputs also have onboard mic preamps and full processing.

Axia console control software.

The new talk studio set up. This is located where the news room used to be. In order to stay on the air and maintain the old studios, a sort of musical chairs system needs to be played. In the end, the WEBE studio and one production room will end up where they started, everyone else will be in a new space. The news room will end up where the current WICC control room is.

Network audio switches.

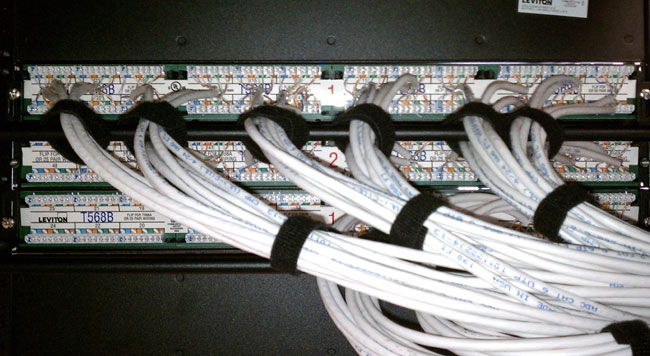

Network patch panel, notice the T568B markings.

Currently, the program directors are loading all there material in the Op-X system. The time schedule is to transfer WEBE into a temporary studio in about two weeks.

More updates as the project progresses.

Update: The new Axia equipment and Op-X automation is on line as of 2/24. More pictures to follow.

Update 2: For more information on how the Axia consoles are made, check out A broadcast console makers perspective.

Update 3: More pictures:

WICC studio is nearly done, just a few odds and ends here or there. This is located where the former talk studio was located.

WICC talk studio, host and four guest positions. This is located where the former news room is.

This is the former WICC control room. It has been gutted and several walls are being removed. This will become the permanent WEBE control room when it is finished.

WEBE temporary control room.

The former WEBE control room, gutted. All the carpeting has been removed and 1/4 inch drywall is going over the old, glue encrusted drywall. This room will become a production room.

WEBE WICC rack room viewed from the hallway, approximately where the door to the room used to be. The old racks to the left are being stripped out and removed. All of the stations are now on the air from the new racks.