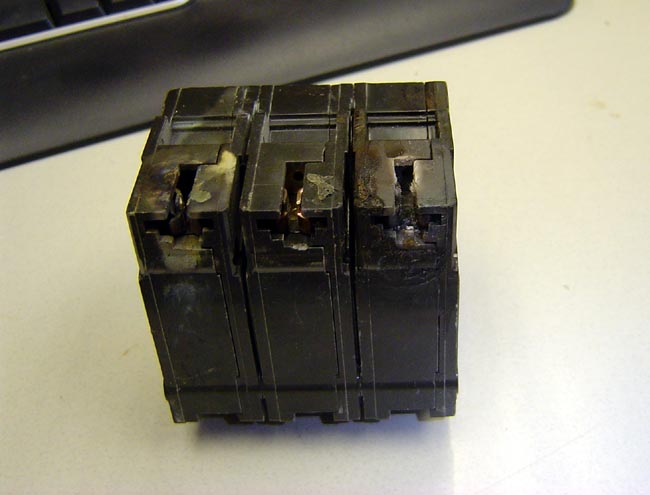

This is yet another addition of the “Burned up Sh*t” collection:

It is a breaker from a 5-ton AC compressor. Back in the bad old days when I was the Director of Engineering for a 28-station group Headquartered in Harrisburg, PA, I received a phone call from one of the local engineers. He stated that the studio AC unit compressor had burned out again and the breaker kept tripping. What did I think, asked him. I thought perhaps he should dig a little deeper and determine why the breaker was tripping before throwing another AC compressor at it. When are you coming to town again, he cheerfully inquired.

Okay, I get it.

I started by calling the HVAC company to inquire what had gone wrong with the compressors. Winding shorted to the case for both units was the answer received. It being July and mighty hot out, the various worker bees in the studio were feeling inconvenienced by the sweat in their eyes and dripping on their work, etc. I called the local manager and asked for a hotel room, I’d be up tomorrow. Then I called the HVAC guy back and asked in to meet me at the studio tomorrow afternoon.

Upon arrival the next morning, I found the fifth-floor studios to be hot, as reported. I trip to the roof location proved to be hotter still. I tested the voltages at the compressor unit with a DVM and everything looked good. A trip down to the utility room found the electrical panel in reasonable shape. Then the local engineering guy chimed in, “Oh yeah, I forgot to tell you, the breaker hums and gets hot when the compressor is on.”

It’s always that little bit of missing information…

I took the breaker out and sure enough, the fingers were all arched and nasty-looking.

I replaced the breaker, the HVAC guy showed up, with a new compressor and the studios began to cool off around 3 p.m.

Since then, I have specified Square D QO bolt-on breakers for new installations, especially for heavy loads like AC units, transmitters, and so on. They are a little more expensive, but in light of two AC compressors, the unscheduled trip out of town, and the grumbling staff, it is better to pay upfront for better equipment than to put up with preventable outages.