I wrote a little Haiku about Thanksgiving dinner:

Telephone rings

Old transmitter beckons

Dishes get cold

Not exactly the 5/7/5 of a traditional haiku, but close enough. This year, it was the nearly 30-year-old Broadcast Electronics FM35A at WEBE. A set of readings from the remote control reveal; zero forward power, zero plate current, and 12.8 KV plate voltage. My first assumption was some sort of drive issue; a failed exciter or IPA driver. After starting the backup transmitter and making sure that it was running stably, I spoke with the program director and told him we would be out the next morning.

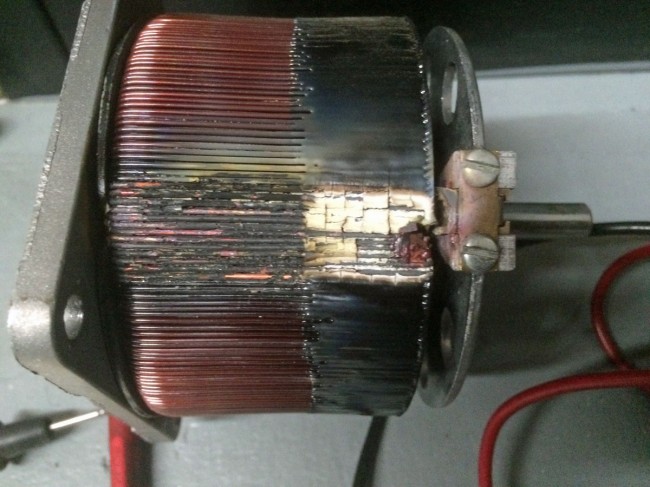

Upon arriving at the transmitter site, I found the BE transmitter had no filament voltage. An obvious clue, I began working backward from the tube socket until I found this:

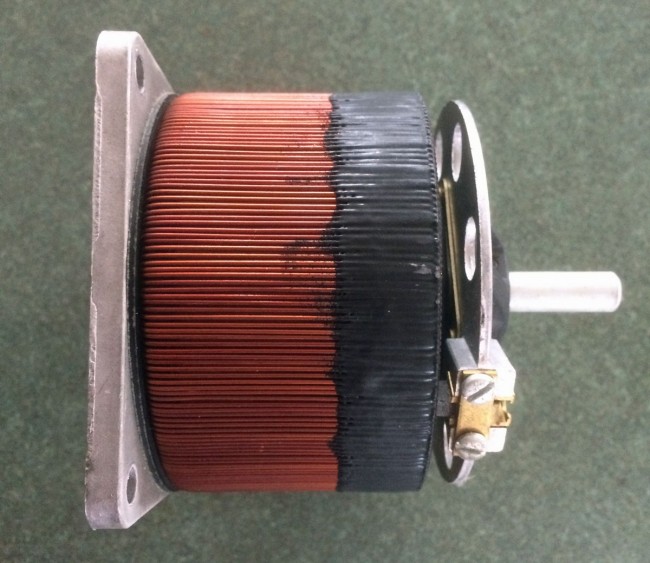

This is the auto-transformer that regulates the filament voltage. Schematically, it is noted as T204 and it is in series with one side of the filament transformer. This one is burned open. The bad news; Broadcast Electronics does not stock this part, it is a special order item, the replacement part costs $2,800 dollars and it will take a few weeks to get here. The good news, after digging through our stock of old transmitter parts, I found an exact replacement:

We will be installing it on Monday morning.

Hording odd pieces-parts is not a bad thing.

Transmitter failure

Old stock comes in handy

Save almost three grand

(oops I left out a syllable… second line should read

“Old stock comes in handy now”

@Paul: Did this failure occur while the rig was on the air? I know some sites “exercise” their main / alt transmitters by alternating them on a schedule and I don’t recall if WEBE had done that even as far back as when I was there.

How is that autotransformer able to handle the current of the 4CX20,000 final? The final has a filament current of 140A at 10v. The autotransformer is only rated for 18A. Since the autotransformer is designed for 40v, they aren’t using it on the primary side of the filament transformer, are they?

Bill, yes the failure occurred while the transmitter was on the air.

Jon, The autotransformer is on one side of the primary leg going into the filament transformer. The filament transformer is 240/208 V primary, 10 V secondary. At 208V, that equates to about 3.5 amps per primary leg of the filament transformer, well withing the unit’s 18 amp rating.

It is more than a little scary that BE doesn’t stock a critical, long lead time part like that. The bean counters are saving on inventory costs while the company burns from the customer service department on up.

The B series uses the same part and I’d be willing to bet it is in the current T series, too. I wonder if anyone buys new tube rigs?

The transmitter business is getting very tough for the companies that haven’t continually innovated. I fear that we’ll soon be down to two major brands, and the other transmitters will be orphans. I hope I am wrong.

I’ve normally been able to get those from Newark, often from stock. I see this one has a two week lead. $304.03 P/N 98F2489

$2,800 is quite a markup considering there aren’t any on the shelf.

Lowell, I was going to make the point that this a a 28 year old transmitter, however, if they are still using the same parts in the newer T series transmitters, then yeah, I would think they would have it in stock.

Chuck, wow, good find. I didn’t even thing of looking at Newark or any of the other parts places, but it is a really simple item. BTW, 2,800 was for a new filament transformer and auto transformer replacement. BE wanted to sell me both parts because they have changed the circuit and their new auto transformer would not work correctly with the old filament transformer.

Another thing Newark can provide is replacement graphite wiper arms for Variacs and Powerstats. I found that if the windings aren’t burnt up you can get the replacement arms for a small fraction of the cost of the whole assembly. This was in a 30kW BE FM transmitter screen power supply, where the APC caused the wiper to move frequently and wear out.

Steve,good on ya!

While we’re at it,let’s not forget Digikey,Grainger(if you’re handling HVAC and other heavy plant maintenance) and Mousser as truly fantastic suppliers of components/assemblies.

You simply need to know exactly what you want and what you’re doing.This is not an endorsement of these companies beyond stating that they’ve saved me buckets of time and money over the years.In a time when manufacturers keep very little on their shelves,they are often sourcing from companies such as these and charging us a signifigant mark-up.

Of course,your own cost vs. time vs. competance analaysis is your guide here.

Oh,and one more thing;One of these “box houses” hasreginal storage facilities around the country/world which is a great strategy these days! Many eggs in many baskets means that a local dissaster is less likely to close down the support buisness(including mine) as was the case with Sony in Japan.They were forced to kill off support of some of their legacy products much earlier than the market is comfortable with.