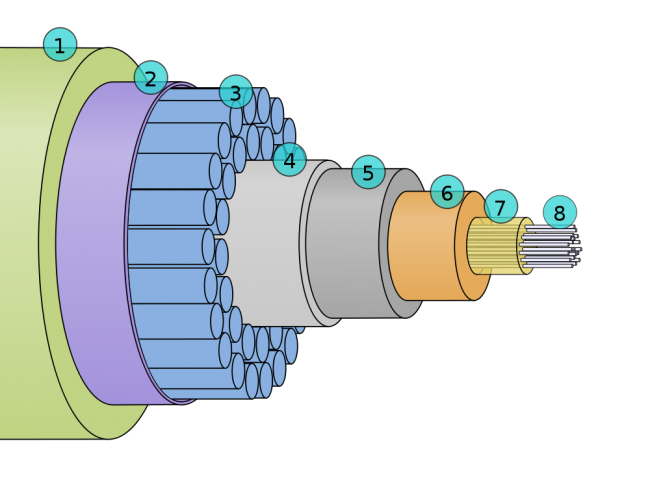

It may be surprising to some, but the number of wires allowed in any given conduit is not “as many as can be jammed in there.” The National Electrical Code, AKA NEC or NFPA 70 gives specific guidance on the number of current-carrying conductors allowed in any specific size and type of conduit.

This is due to the fact that current-carrying conductors generate heat. Cables enclosed in a conduit need to dissipate that heat so that the insulation on the cable doesn’t melt, which would be a bad outcome.

Conduit fill tables are found in Chapter 9 of the NEC. There are several tables that give the number of conductors for each size and type of conduit. Then there is the general rule of thumb that for more than two cables, the maximum conduit fill is 40%. This comes in handy when several different size conductors are being run in the same conduit.

An example of this is when several circuits are going across the room to the same general location, in this case, a row of transmitters and racks. Instead of running individual conduits for all those units, one or two conduits from the electrical panel are run to a square wireway, then the individual circuits are broken out and wired from wireway to the individual loads. In this case, the following equipment is being connected:

- Harris FM25K: 100 amp 3 phase high voltage power supply (#2 THHN), 30 amp 3 phase transmitter cabinet (#10 THHN)

- Harris FM3.5K: 70 amp split phase (#6 THHN)

- Harris MW1A: 30 amp split phase (#10 THHN)

- Two equipment racks: 20 amp single phase (#12 THHN)

- Coax switch: 15 amp single phase (#14 THHN)

- Dummy Load: 15 amp single phase (#14 THHN)

- Antenna switch/dissipation network for AM station: 15 amp split phase (#14 THHN)

- Convenience outlets for the back wall: 20 amp single phase (#12 THHN)

Excluding grounding conductors, which will be addressed below, the total current carrying conductor count is thus:

- #2 THHN: 3 each

- #6 THHN: 3 each

- #10 THHN: 7 each

- #12 THHN: 6 each

- #14 THHN: 6 each

Ampacities based on NEC table 310.16, THHN insulation in dry locations, maximum temperature rating is 90° C (194° F) based on the ambient temperature of 30° C (86° F)

Grounding conductors for each of those circuits, based on NEC Table 250.122 (all conductors are copper):

- 100 amp circuit: #8

- 70 amp circuit: #8

- 30 amp circuit: #10

- 20 amp circuit: #12

- 15 amp circuit: #14

The final conductor count is:

- #2 THHN: 3 each

- #6 THHN: 3 each

- #8 THHN: 2 each

- #10 THHN: 9 each

- #12 THHN: 9 each

- #14 THHN: 9 each

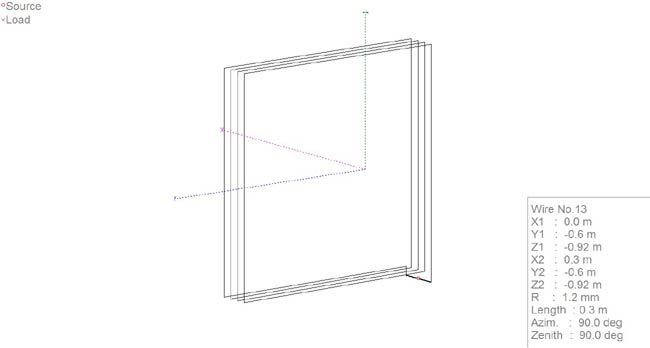

The plan is to use two 1 and 1/2-inch EMT conduits between the electrical service panel and the 4 x 4 square wireway. According to NEC Chapter 9, Table 4, the 40% cross-sectional size of this conduit is 526 mm2. It is easier to simply use metric measurements for this. The cross-sectional wire areas are found in Chapter 9, Table 5. Chart of various conductor sizes and areas:

| Conductor | Area (mm2) | Total conductor | Total area (mm2) |

| #2 THHN | 74.71 | 3 | 224.13 |

| #6 THHN | 32.71 | 3 | 98.13 |

| #8 THHN | 23.61 | 2 | 47.22 |

| #10 THHN | 13.61 | 9 | 122.49 |

| #12 THHN | 8.581 | 9 | 77.229 |

| #14 THHN | 6.258 | 9 | 56.322 |

Thus, in order to break this up into two 1 and 1/2-inch conduits, the #2, #6, and #8 (main transmitter HV power supply, backup transmitter, and grounds) are run in one conduit, the remaining circuits in the other. The idea is that the main transmitter and backup transmitter will not be running simultaneously for long periods of time. Those cable areas total 369.48 mm2, well within the 40% limit of 526 mm2 for 1 and 1/2 inch EMT. The rest of the circuit’s cable areas total 256.041 mm2. That leaves room for additional circuits in the second conduit if future needs dictate. The extra conduit area will make pulling the wires through easy.

From the square wireway to the HV power supply, 1 and 1/4 inch conduit will carry the three #2 and one #8 ground. 1 and 1/4 inch EMT has a cross sectional area of 387 mm2, the conductors contained within will be 271 mm2. Less room here, but still well within the 40% limit.

Pictures will be posted when the project is done.