As a part of the re-wiring of a transmitter site, I realized that the site needed a temperature sensor. I believe it is important for any remote transmitter site to have a temperature sensor, too many things can go wrong at a transmitter site.

I recall one incident at WGNA-FM in Albany, NY where a ventilation fan failed on a hot summer day. The Harris HT-10 transmitter stayed on the air while the temperature climbed through 160 degrees inside the building, finally shutting down when the solid-state driver module failed. This site had a temperature sensor and a live operator taking transmitter readings every three hours. They faithfully logged the temperature increase in three-hour increments but didn’t call anyone until the station went off. When I arrived there, it was so hot inside the building that I couldn’t touch a metal surface.

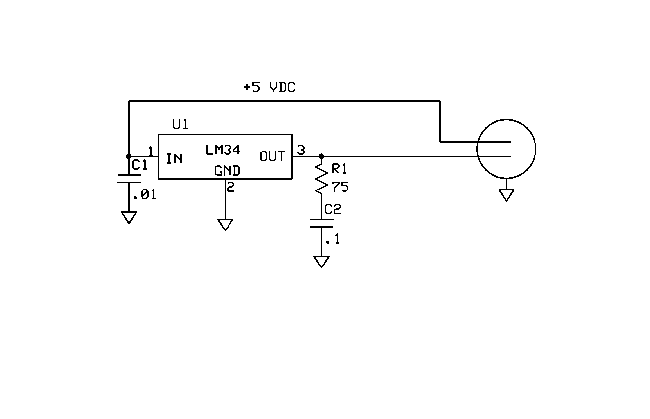

For the present-day project, I looked at the Burk BTU-4, which seemed a little pricey. After doing a bit of quick research, I found the National Semiconductor LM34 a good alternative. This unit puts out 10 mv/degree F, which can be directly calibrated to a metering input of an ACR-16 using the Lin scale. I checked the accuracy by using a piece of melting ice, it was right on. The design and implementation are very simple:

The LM34 is available in TO-46 or TO-92 case. I bypassed the V+ with a 0.01uf capacitor. It should be mounted in a small box with the case of the LM34 mounted on a metal cover or heat sink. The TO-46 version, the case is ground. It can be run on any voltage from +5 to +30 VDC, I used +5 because I had a little wall wart with the right voltage. The wire is any type of balanced audio wire like Belden 8459, etc. The LM34 cost 4 dollars, the rest of the parts were laying around. It took about 15 minutes to create.

The site is air-conditioned, therefore I set the remote control to alarm if the temperature goes above 85 degrees F inside the building.