The rumble of thunder this morning let me know that lightning season is upon us here in the Northeast and likely the rest of the country as well. I used to enjoy the odd summer thunderstorm, especially the late afternoon pop-ups that cool off a hot summer’s day. Now whenever I see lightning or hear thunder I wonder if the phone is going to ring. Chances are good that it will not, as I invested many hours of my time and my previous employer’s money into lightning protection at the transmitter sites.

I go on the assumption that all tall steel towers will get struck, oftentimes repeatedly, during any particular electrical storm. Back in the day, I took a course by Polyphaser called “The Grounds for Lightning and EMP Protection.” It was a great primer on how to ground and bond equipment at a transmitter site to eliminate current flow, which is the cause of all EMP and lightning-induced failures. When I was in military communications, no expense was spared as they took uptime very seriously. Any downtime was a personal affront to the commanding officer of the unit in question.

Lightning is DC however, it behaves more like 10 KHz – 2 MHz AC. Therefore, lightning and EMP grounding systems need to be designed and installed to accommodate DC through 10 KHz AC voltages. This is easily done by choosing the correct conductors, ground bus bars, and bonding systems.

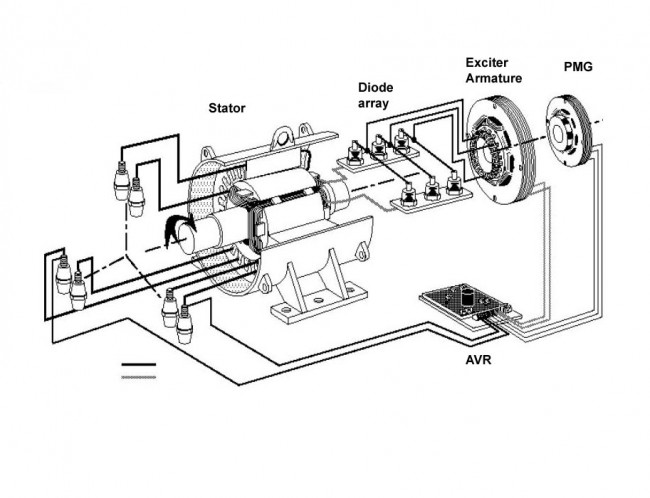

The other path lighting takes into a transmitter is through the AC mains. Utility company high voltage primary feeds act like large antennas for lightning-induced EMP. Fortunately, much of that is filtered out by the step-down transformers just before the building service entrance. It is still possible, however, for some impulse voltage to make it through the transformers and into the service entrance panel. On older tube type transmitters, this could often damage the plate voltage power supply because of the voltage multiplication factor of the plate transformer. Oftentimes, the transformer secondary would have “holes” punched through the insulation to ground. This is an expensive and time-consuming repair.

I would conservatively estimate that for every $10.00 spent on lightning protection, $1,000.00 dollars worth of damage and downtime is saved. Overall, a pretty good return on investment.

The basics for lightning ground bonding are thus:

- Use the lowest inductance wire possible. The industry standard is #2 solid copper, however, if bonded properly, there will be very little current flow inside the transmitter building, so if #2 is not available, then any solid wire up to #8 will work. Tower ground bonding should be as heavy as possible.

- Ground all guy anchor points, and bond all guy wires together and to the same ground rod or ground rod system.

- Keep the bonding conductors as straight as possible, bends should be long sweeping turns to minimize series inductance.

- All metal equipment should be bonded, no rack, telco demark, electrical panel, dummy load, bulkhead entrance grounding bus, combiner, door frame, etc should be left unbonded.

- All coax outer shields should be grounded where it comes into the building.

- All coax cables should go through a toroid before being connected to the transmitter.

- All outdoor bonding connections should be exothermically (CAD welded) bonded to ground rods.

- All grounding must go to a common ground point, AKA star grounding point. No individual ground points should be allowed in the building.

- Multiple ground rods were installed around the outside perimeter of the building as deeply as possible. Some mountaintop transmitter sites may require special grounding material (Bentonite) and or to have a ground well drilled. Ground conductors should have as much surface area contact with Earth as possible.

The whole idea is to present a low-resistance ground path and keep all of the equipment at the same potential to minimize the current flow between equipment.

For the electrical building service entrance, a series surge protector installed before the service panel is the best method. Several are made and they need to be sized for the building service. A fallback is a parallel surge protector that will provide some protection. On the AC mains connections, any series inductance that can be added to increase resistance to the lightning pulse is good. All AC mains connections to the transmitter should go through a toroid before they are connected to the transmitter. This is a good idea for remote control and mod monitor wiring as well.

I have also had great success with GE TLP175 silicon-carbide disks on secondary feeds at the kilowatt-hour meters. Square D also makes them, but I can’t remember the number. Wilkinson also made some real large ones in the ’70’s for single and 3-phase high power FM and TV transmitter feeds in a NEMA 1 enclosure. These serve as a path to ground for lightning transients coming in on feeds from the serving electrical utility. They will take many strikes and will last a long time.

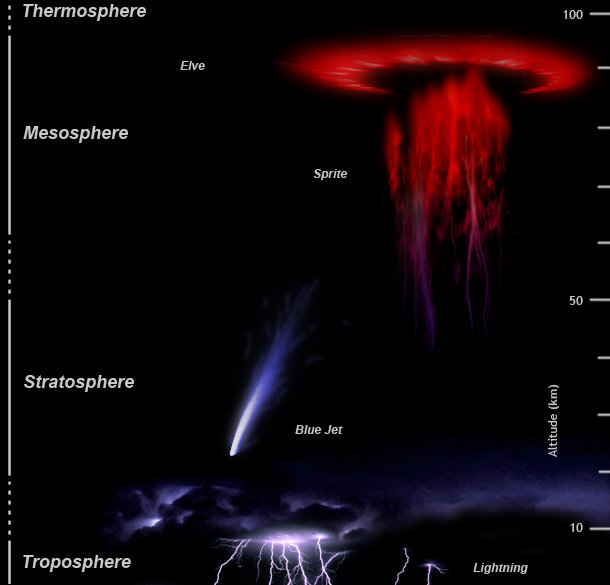

We’ve had a lot of research on lightning performed in Huntsville; the sprites were discovered by a curious scientists who borrowed time on a parked/stowed Space Shuttle camera. “Lightning” “NASA” “MSFC” and “Huntsville” should return some interesting information.