At the place of my former employment, there is an issue with AM reception. The building is full of old, electrically noisy fluorescent light ballasts, computers, mercury vapor parking lot lights, and every other electrical noise generator under the sun. The second issue is that one of the EAS monitor assignments for two FM class B stations is WABC in NYC. Under normal conditions, WABC puts a fine signal into the area. Listening to it is not a problem at my house, in the car, and whatnot. However, at the studio, the station is audible but terribly noisy. Every time one of those FM stations ran a required monthly EAS test originating from WABC, it was full of static and just sounded bad on the air.

The state EAS folks were inflexible as to the monitoring assignment. “WABC is the PEP station for NY. You should have plenty of signal from WABC at your location,” said they.

At one time, the studio had an active loop antenna (LP-1A) from Belar, which worked but also seemed to amplify the noise. I decided that the best thing to do was go big and ditch the preamp. I made a diamond-shaped receiving loop on two pieces of two-by-four by eight-foot lumber. I wound four turns of #14 stranded wire around this frame and made a 4:1 balun to feed the unbalanced 75-ohm RG-6 coax.

That cured the noise problems and for eight years, WABC sounded pretty good on the EAS monitor.

Fast forward to about a week ago. The roof at the studio building was being redone and all the monitor antennas had to be removed from the roof. The homemade loop was not in good shape. The balun box was full of water, the lumber was cracking and falling apart, the insulation was degraded by UV exposure, etc. My boss asked, “How much to make a new one?” So I said something like forty dollars and a couple of hours. He then said, “Make it so we don’t have to ever make another one.”

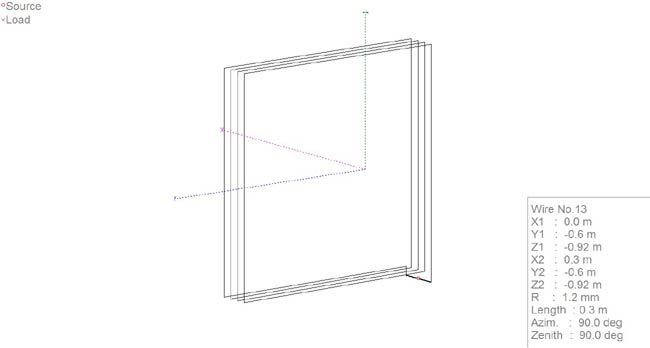

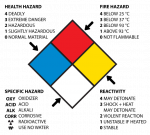

Music to my ears. I started by checking my assumptions. I made a model and ran NEC to see what the electrical characteristics for that size loop were on 770 KHz. It came out better than I thought, with about 1-ohm resistance and 282 ohms inductive reactance. Fooling around a little more showed that roughly 1.3 uH inductance and 720 pF capacitance in an L network would bring this in line for a 50-ohm feed point. Since this is a receive-only antenna, that is not a prime consideration. I am more concerned with noise reduction and maintaining at least the bi-directional quality of a loop antenna.

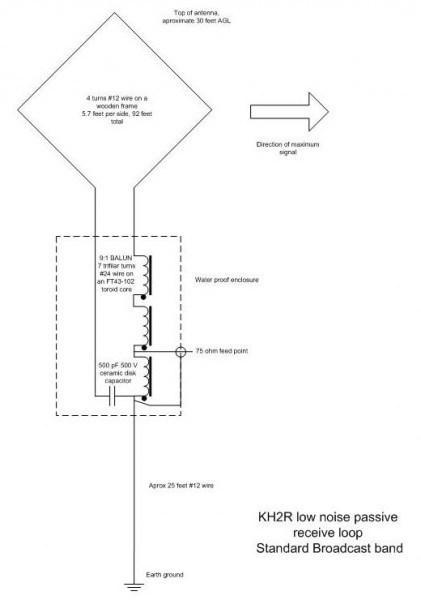

Then, I decided to get fancy. What if the capacitance was put on the end of the loop to ground instead of the feed point? That, in effect, should make the loop directional off of the unterminated side. Driving the feed point with a 9:1 balun would also bring up the inductance on the feed point. Finally, grounding the whole thing with a separate ground lead might also get rid of some noise.

The final configuration looks something like this, which is essentially a top-loaded vertical:

Now to build it.

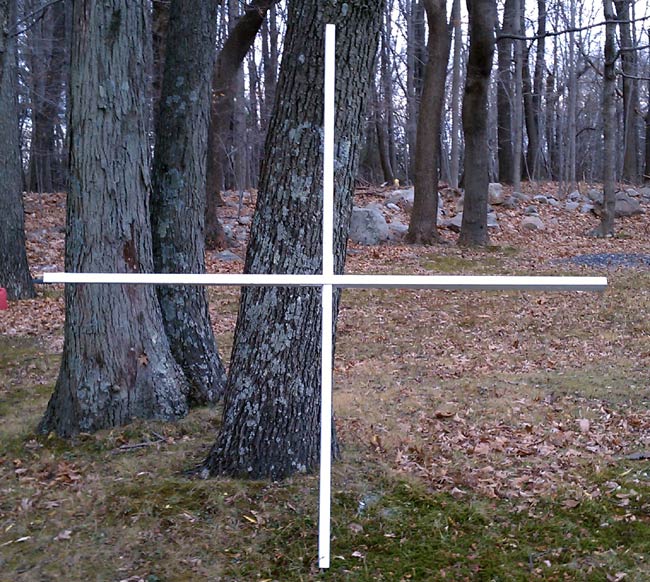

Once again, I felt that a non-conductive support was needed, so I used two by four by eight-foot lumber, but this time I painted them with oil-based paint. The side length worked out to be 5.7 feet per side, or 23 feet per turn for a total of 92 feet of wire.

I purchased 100 feet of PV (photovoltaic) wire (Alpha wire PV-1400), which is UV, heat, and moisture resistant and designed to last for 30 years in outdoor, exposed environments.

For the balun box, I used a metal outdoor electrical box with a metal cover. I put a ground wire jumper between the box cover and the ground common to maintain shielding. I used a water-tight bushing to feed the antenna wires and the ground wire into the box. I drilled a 3/8 hole for a type F chassis connector. Everything was given a little extra waterproofing with some silicone-based (RTV) sealant on all threaded junctions.

The spreaders for the wire windings are UV-resistant 1-inch PVC conduit. I drilled four holes, three inches apart in each spreader to run the loop wires through.

The balun is 7 trifiler turn of 24 AWG copper wire on an FT-43-102 toroid core. Trifiler means three wires twisted together before winding the toroid core.

I used all stainless steel screws and mounting hardware.

The loop is terminated with a 500 pF, 500-volt ceramic capacitor to ground. Once in place, I am going to experiment with this by jumping it out of the circuit to see what effect it has on noise and signal strength. I may also try replacing it with a 200-ohm resistor and or a 1000 pF capacitor.

The assembly was pretty easy, although time-consuming. My four-year-old son helped me paint the wood and string the wires through the spreaders.

I soldered all wire connections with 5% silver-bearing solder.

When the whole thing was assembled, I tested it out with my Drake R8 receiver. It performs much as expected, with low noise, directional away from the terminated wire loop. It does not appear to be too narrow-banded either, as the stations on the high end of the dial were also received with good signal strength.

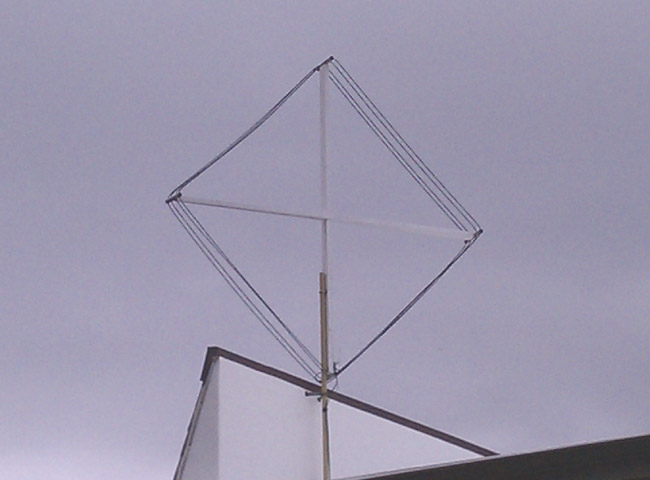

Next was loading it on the pickup truck, driving it in, and mounting it on the studio building. I got some funny looks from my fellow travelers, then again, I usually do.

For the ground, I purchased an eight-foot copper-clad grounding rod and pounded it into the ground at the corner of the building. This area is always wet as it is the lowest area around the building and all the gutters drain there. This is not best RF ground, but for the purposes of this antenna, it should work fine. I used about 28 feet of leftover #12 stranded wire from the ground rod up to the balun box and connected it to the common ground point inside the box.

The frame itself is mounted on a standard wall-mount antenna pole. Stainless steel clamps hold the wood frame to the pole.

Once it was installed, I used my Kenwood R-2000 receiver to find the best mounting azimuth and locked everything down. I also put a toroid on the RG-6 coax coming up from the rack room to keep any shield noise from getting into the antenna.

The tuning capacitor is in there too, behind one of the loop wires.

Antenna installed. I did try substituting the 500 pF capacitor with a 220 resistor. The signal strength came up somewhat, but the noise increased more, therefore the capacitor is a good termination for this antenna.

With this antenna, the signal from WABC is nice and clean and sounds good on the FM station when a monthly EAS test is retransmitted.

I had a similar problem about 20 years ago and constructed a loop out of 1/2 hard-drawn copper pipe and sweat (solder) fittings available at Ace Hardware. The “gap” used a PVC coupling epoxy-ed to the copper pipes. Wire inside was #14 AWG THHN stranded building wire. I used a Hubbell lighting weatherproof box with mounting ears as the base and fed it with 300 ohm TV “twin-lead”. Antenna is still in use today!

I too have had difficulty with the Belar LP-1A. Sometimes it works great and sometimes it’s less useful than jamming a paperclip into the coax screw. Indoors lately I’ve been using a Tecsun AN100, cheap and simple… my style.

hello, have a 1936 zenith am/shortwave radio,what is a good antenna set-up for me i’m new to radio and need help radio works good but need better reception for foreign broadcasts. thanks john

John, I would start with a simple wire, the longer the better. Keep wire away from AC lines, street lights, fluorescent lights, etc and it should work. After that, experiment with different designs, it is fun!

I know that this article is several years old but it has the info I need for a solution. But, I was wondering about the toroid you used and where to locate one. I have searched for that number you used (FT-43-102 toroid core) but have had no luck in location it. Any suggestions? I think that your design is exactly what I’m needing for my situation.