To any who lives in the capital region, the WGY tower near the intersection of I-90 and I-88 in the town of Rotterdam is a familiar site. It is big, tall, and conspicuously marked with a huge “81 WGY” on the southwest face of the tower. At night the call letters used to be lit up by a spotlight but that may have been turned off in recent years.

In my time as chief engineer there, I found several file folders of memos and other materials about the building of the tower, which started in 1936. Prior to that, WGY used a T-top wire antenna, first from the General Electric plant in Schenectady (1922-25) and then from the current tower site in Rotterdam. Located with WGY were GE’s experimental shortwave stations W2XAF and W2XAD.

When the station increased power to 50,000 watts in 1925, many reports of fading were received from locations 20-50 miles away. WGY engineers studied the situation by doing a full proof on the antenna. They found an elliptical-shaped pattern with nulls to the north and south. This coincided approximately with the T arms of the T top antenna, likely due to the self-resonating effect of the support towers for the ends of the T.

NBC, then owners of WJZ (now WABC) in NYC had studied this problem for years and came up with a new antenna design for Standard Broadcast, the uniform cross-section guyed tower. Starting in 1935, WGY began to investigate installing such a tower in South Schenectady, as the transmitter site was then known. One report showed an efficiency gain of 430% over the T top antenna that was in use. The General Electric construction and engineering department raised several objects to the standard triangular tower then and now commonly used for AM radiators.

Much mechanical planning and effort went into the design of the tower, which is a square tower, a 9-foot face, 625 feet tall. During the planning phase, KDKA was installing a similar tower, which collapsed when it was being erected in 1936. An analysis of the failure showed that one of the guy anchor cable sockets pulled out of the concrete (which was improperly poured). This may also be the reason why the KDKA tower collapsed in 2003, although I never read the engineering report on that failure. Nevertheless, GE Engineering felt that forging the members of a triangular tower weakens them and was too risky, thus, a square tower was the solution.

Further, every component of the tower was tested individually. Often, two of a type were build, with one being tested to destruction. Two base insulators were made for this specific tower. The first was tested to destruction at the National Standards and Institutes laboratory in Washington DC. It was found that the insulator withstood slightly more than 1,200,000 pounds of pressure. The working load (tower dead weight) of the base insulator is calculated to be about 430,000 pounds, thus almost a 3:1 safety margin.

The wire rope used for the guy wires was also tested to destruction. The working load on the upper guy is about 24,000 pounds, the wire rope broke at nearly 120,000 pounds. The concrete, guy anchor sockets, T bars, and all other parts were likewise tested.

Electrically, the tower is 186 degrees (it was 180 degrees on 790 kHz, the former WGY frequency). It had a 40 X 40 foot ground mat with 120 buried ground radials. The ground radials were #4 hard drawn stranded copper. When we investigated the system in 1999, it was complete and unbroken. The radials, ground screen, strap and all other metal component showed no signs of deterioration. It helps that the soil surrounding the tower is a sandy loam and well drained.

The tower was fed with 600 ohm open transmission line, 180 degrees long. Initially, the system had been designed for high power operation up to 500 KW. However, when the transmitter was replaced in 1980, a new Harris ATU was installed, which can only handle 50 KW. I recall the base resistance to be 192 ohms with -j85 reactance.

A concrete wall surrounds the base insulator. This was installed in early 1942 to prevent the base insulator from being shot out by sabbators during WWII.

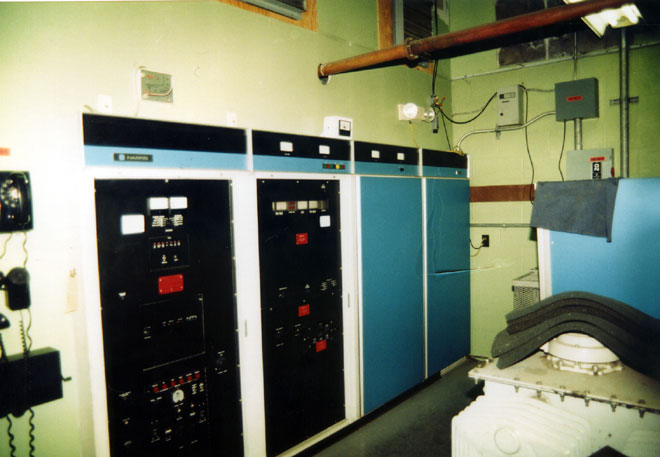

When I worked there, the station had a Harris MW-50B transmitter. This unit was in slightly better shape than its counterpart at WPTR across town. I did find some of the same quirky things with it, however. Our consulting engineer had a good line, “Harris, where no economy is spared…”

The site had a FEMA owned backup generator installed in the 60’s. This was an Onan 225 KW diesel powered unit. 225KW is likely a conservative estimate as those units were way overbuilt. The original fuel tank was buried out behind the building. FEMA contracted for it’s removal in 1995 because of concerns of leaks and soil contamination. When they dug it up, the primer was still on the tank. After getting the tank out of the ground, the contractor cut a large hole in it and lowered a person into the tank to clean it out. Something that should be profiled on the Dirties Jobs TV show.

The new tank was installed in the old outdoor transformer vault. It is a 5000 gallon double walled above ground tank with monitoring system.

It has been several years since I have been to this site. I know they installed a Harris DX-50 sometime in 2001 or so. They also may have replaced the open transmission line. WGY now transmits in HD radio, which they are able to do because the tower was well designed and installed.